Rockwell Automation 1326AB, 1394, 842A Absolute Encoder Feedback Adapter Kit User Manual

Page 2

2

1326AB Absolute Encoder Feedback Mounting Adapter Kit

Publication 1326A-5.29 February 2000

Installing the Encoder Feedback

Mounting Adapter Kit

Important: This adapter is designed to accept Allen-Bradley 842A

encoders only.

To install the encoder feedback mounting adapter kit:

1. Remove the back plate and gasket from the end of the motor

(discard the old gasket). Refer to Figure 3 for an overview of the

installation.

2. Thoroughly clean the shafts, coupling bores, and mounting faces

to remove oil or any other substance that may be present.

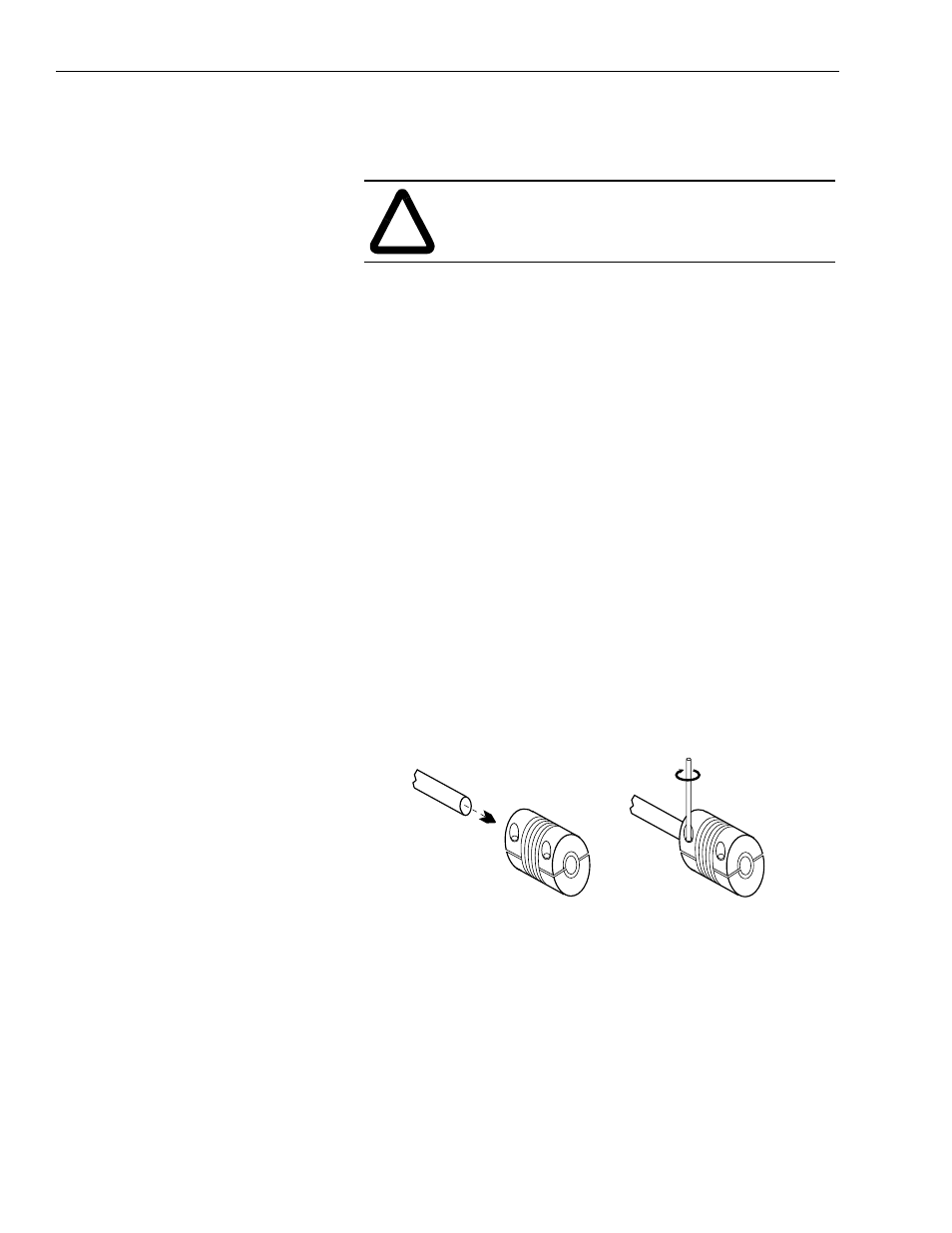

3. Using the allen wrench supplied in the kit, attach the flexible

coupling to the stub shaft of the motor (refer to Figure 1 below).

When tightening, use no more than 1.8-2.0 N-m (16-18 lb-in.) of

torque. The shaft must be visible through the spacings in the

coupling.

Important: The flexible coupling contains an insulating sleeve

on one end. The sleeve guards against motor

generated heat migrating to the encoder. The

coupling end with the insulating sleeve must be

positioned towards the encoder.

Figure 1

Attaching the Coupling to Motor Shaft

Important: The coupling is a flexible type that must be installed

in a relaxed state (not compressed or stretched).

Installation in the compressed state will limit the

ability of the coupling to flex adequately.

Installation in a stretched condition might exceed

the couplings yield point when flexed. Either

condition will shorten the life of the coupling.

4. Attach the encoder to the adapter using the screws supplied.

Tighten the screws using no more than 2.3-2.8 N-m (20-25 lb-in.)

of torque.

!

ATTENTION: To avoid a shock hazard, ensure that

all power to the motor is removed before installing the

adapter.

Coupling

Motor Shaft