Rockwell Automation 802B Compact Limit Switch User Manual

Rockwell Automation Equipment

1

Installation and Operating Instructions

Bulletin 802B Compact Limit Switch

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

This publication does not include specifications, dimensions, and other installation considerations.

Refer to the product catalog pages for additional information.

!

WARNING:

To avoid electrical shock and/or unintended operation of equipment, disconnect all power to the limit

switch and the controlled equipment before proceeding with any repair or adjustment of the limit

switch.

Overview

Limit Switches are used in electrical control systems to sense

position. They are actuated by the predetermined motion of a

cam, machine component, or piece part. This mechanical

motion is then converted to an electrical signal through the

actuation of a set of contacts. These signals can be used in

the control circuits of solenoids, control relays, and motor

starters to control the operation of conveyors, hoists,

elevators, machine tools, etc. They are not to be used to

directly control a motor.

General Data

•

Enclosure Rating: NEMA 1,3,4,6,12,13 and IP67

•

Mechanical Life: Approx. 10,000,000 operations

Ê

•

Electrical Life: Approx. 200,000 operations (3A 250V AC,

resistive load)

Ê

•

Operating Speed

G

Top Push: 0.1mm to 0.5m per second

G

Side Rotary: 1mm to 1m per second

•

Operating Frequency:

G

Mechanical: 120 operations/minute

G

Electrical: 30 operations/minute

•

Operating Temperature: –10

°

C to 70

°

C (14

°

F to 158

°

F)

with no icing

•

Short Circuit Protection: Quick blow fuse suitable for rated

current is recommended.

Ê

Life expectancy has been calculated at an operating temperature

of 5

°

C to 35

°

C (41

°

F to 95

°

F) and an operating humidity of 40% to

70%.

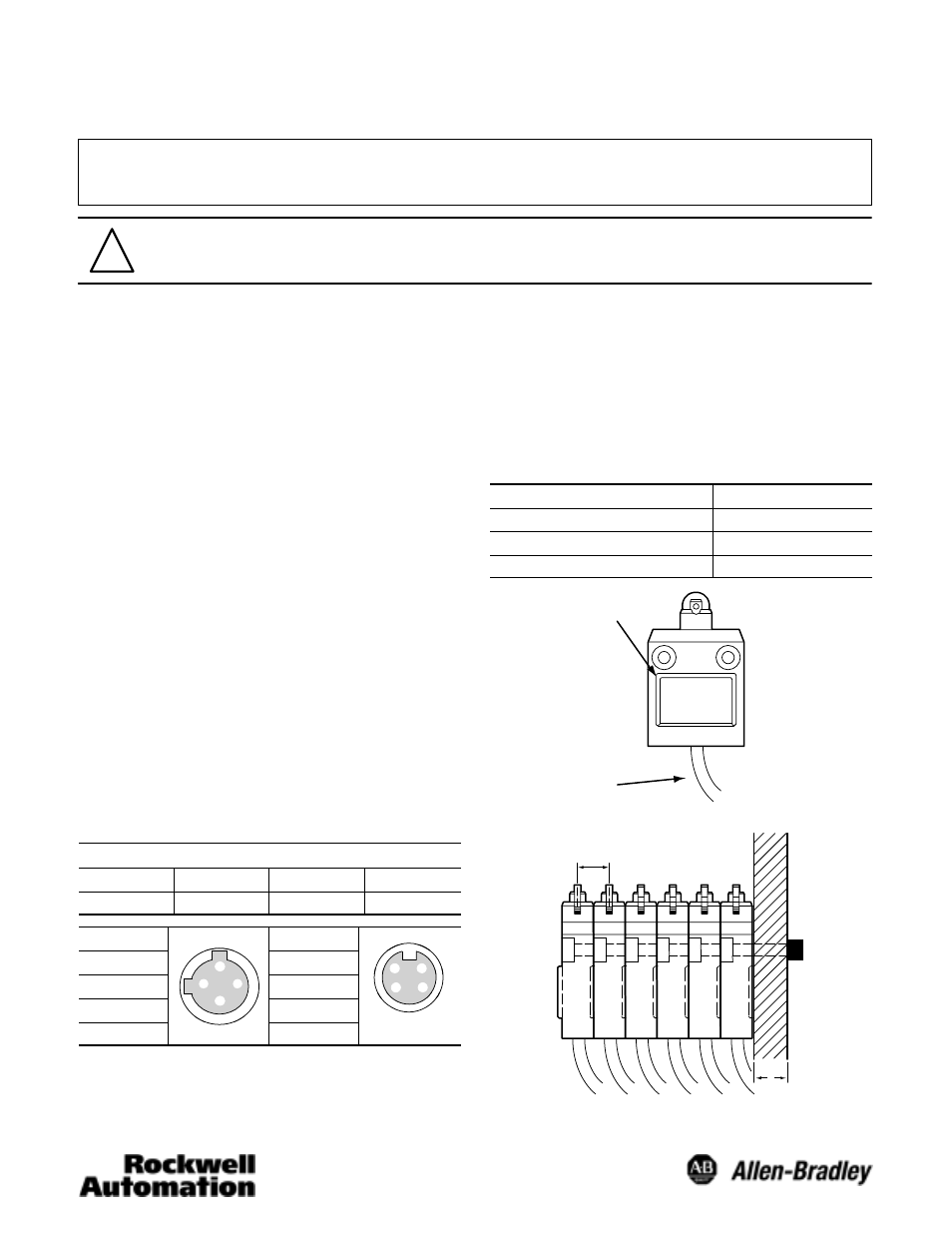

Wiring

PreĆLeaded Models

COM

NO

NC

G

Black

Blue

Brown

Green/Yellow

AC QD Pin-out:

DC QD Pin-out:

Pin 1 = Common

2

Pin 1 = N/O

2

1

Pin 2 = N/O

2

1

4

3

Pin 2 = Common

4

3

2

1

Pin 3 = N/C

4

Pin 3 = Grnd.

M l R

t l

Pin 4 = Grnd.

Pin 4 = N/C

Male Receptacle

Mounting

Units should be mounted using the mounting holes provided.

These mounting holes are counter boarded to help contain

the bolt heads. The use of M5 Cap Screws, (Hex head), and

washers is recommended. Mounting bolts should be torqued

to a value between 4.90 and 5.88 Nm. These units have been

designed to enable gang mounting. In the case of ganged

mounting, the installer should fit the convex part of the gang

mount guide into the concave guide of the adjacent switch. A

maximum of six switches may be ganged. Special units that

have been designed for panel mounting will be provided with

a threaded head. These switches will also have washers and

a mounting nut included with the switch.

Hardware

Torque

Head mounting screw

0.78 to 0.88 N@m

Side rotary shaft bolt

4.90 to 5.88 N@m

Unit mounting screw

4.90 to 5.88 N@m

GangĆmounting guide

(convex front and

concave rear)

Mounting Panel

16mm

45mm

bend radius

6mm