Rockwell Automation 440P-WM4 Metal Spring Rod Installation/Operating Instructions User Manual

Rockwell Automation Equipment

Installation and Operating Instructions

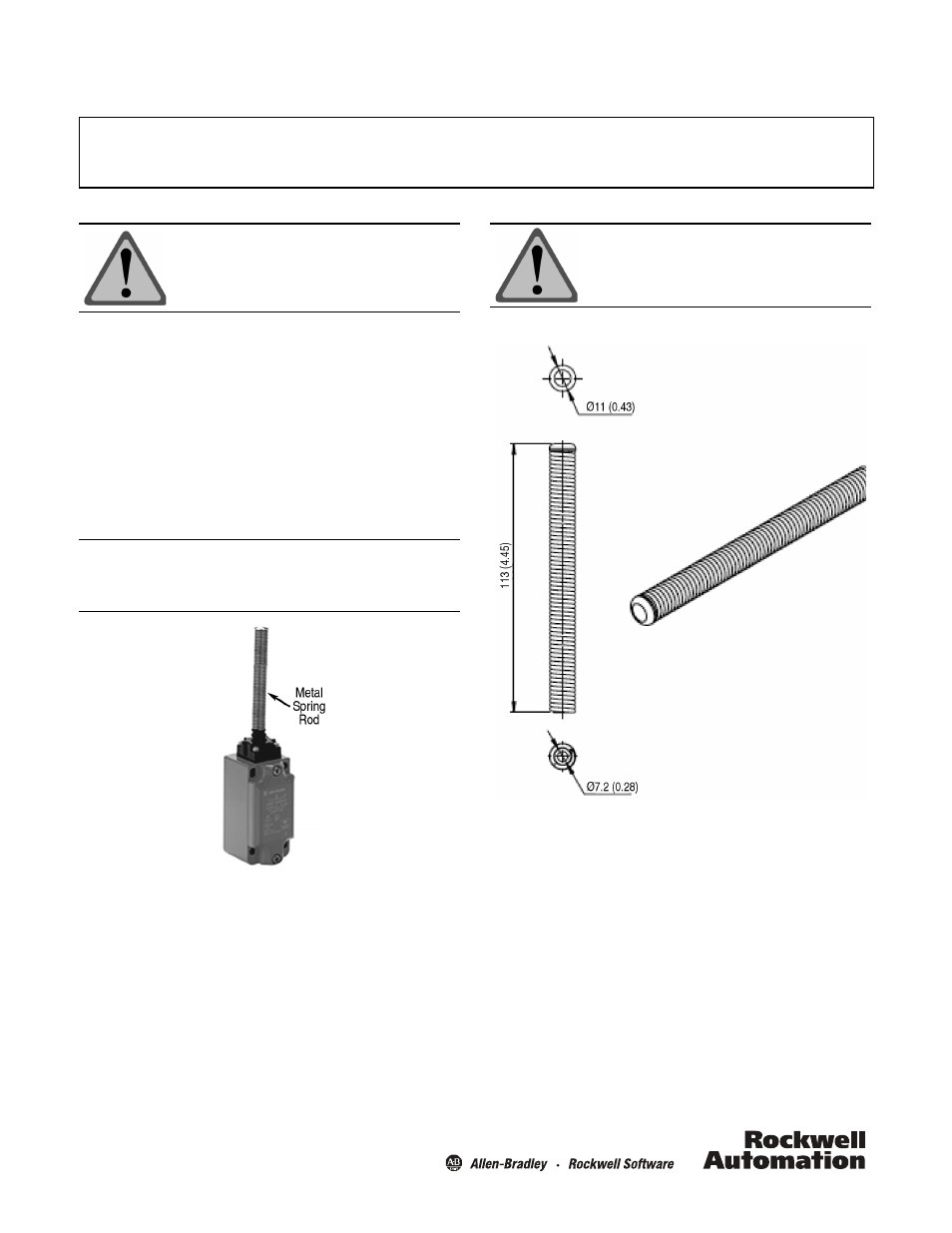

Bulletin 440P-WM4 Metal Spring Rod

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

This publication does not include all specifications, dimensions, or any special installation considerations.

Refer to the product catalog pages for additional information.

General Data

• Designed for 440P-M metal spring rod limit switches

• Spring rod diameter 11 mm (0.43 in.)

• Spring rod length 113 mm (4.45 in.)

Principles, Standards, and Implementation

Operating specifications must be followed. Actuators should

be displaced beyond the point where direct opening action

occurs. If adjustable actuators become loose they may defeat

the direct opening action feature of the limit switch. These

devices are not to be used to directly control a motor.

ATTENTION: To avoid electrical shock and unintended

operation of equipment, disconnect all

power to the limit switch and the controlled

equipment before proceeding with any

repair or adjustment of the limit switch.

IMPORTANT: Installation of Allen-Bradley limit switches should be in

accordance with local and/or national codes. Servicing

energized industrial control equipment can be hazarous if

not in accordance to recommended safety procedures.

Metal spring rod shown installed.

Approximate Dimensions [mm (in.)]

Instructions

1. Remove old spring rod by holding the rubber gasket at the

base of the spring rod and turning the spring rod counter-

clockwise.

2. Thread the replacement spring rod onto the threaded post

shaft extending vertically from the operator head.

3. While holding the rubber gasket at the base of the spring

rod torque the spring rod clockwise to 1…1.4 N•m

(8.85…12.39 lb•in).

ATTENTION: Operator heads with adjustable actuators

should

NOT be used for safety

applications.