Direction pin, Direction control ê – Rockwell Automation 845G Absolute Encoder, Size 25 User Manual

Page 3

3

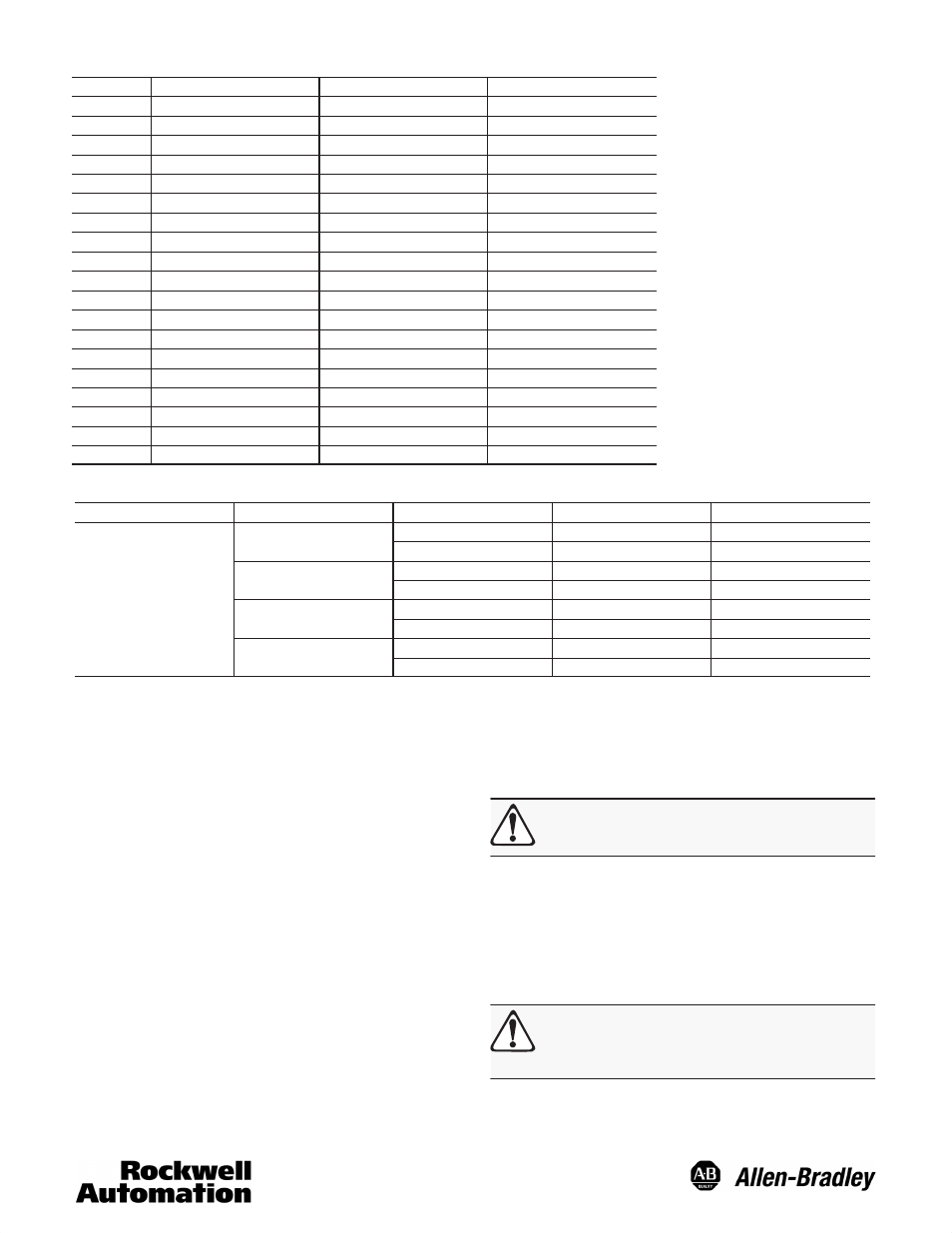

Electrical Connections—19 Pin Connector (Binary Coded Decimal)

Pin

845-CA-D-___ Wire Color

1000 BCD (12 Bit)

360 BCD (10 Bit)

V

Red

+DC

+DC

A

Brown

1

1

B

Orange

2

2

C

Yellow

4

4

D

Green

8

8

E

Blue

10

10

F

Violet

20

20

G

Gray

40

40

H

White

80

80

J

White/Orange

100

100

K

White/Brown

200

200

L

White/Red

400

N/C

M

White/Yellow

800

N/C

N

White/Green

N/C

N/C

P

White/Blue

N/C

N/C

R

White/Black

Direction Control

Direction Control

S

White/Violet

Reset

Reset

T

Black

DC Common

DC Common

U

White/Gray

Latch Control

Latch Control

Electrical Connections for SSI Output—12 Pin Connector

Catalog Number

Wire Pair

Wire Color

Function

Pin

Red/Black/Shield

Red

+DC Input

8

Red/Black/Shield

Black

DC Common

1

White/Black/Shield

White

Clock +

3

845-CA-G-__

White/Black/Shield

Black

Clock -

11

845-CA-G-__

(With 12 pin connector

Blue/Black/Shield

Blue

Data +

2

Blue/Black/Shield

Black

Data -

10

Green/Black/Shield

Green

Direction Control

12

Green/Black/Shield

Black

Reset

9

Direction Pin

The Direction Pin can change function with code type. In

parallel type Gray Code encoders, its function is Most

Significant Bit Complement or MSBC for short. In Natural

Binary, Binary Coded Decimal and Gray Code SSI encoders,

its function is Direction Control.

Direction Control

Ê

Natural Binary and BCD

A logic “1” (+DC or open) on the direction control pin will

produce increasing counts with a counterclockwise rotation of

the shaft. A logic “0” (DC common) on the direction control pin

will produce increasing counts with a clockwise rotation of the

shaft.

Gray Code (SSI)

A logic “1” (+DC or open) on the direction control pin will

produce increasing counts with a clockwise rotation of the

shaft. A logic “0” (DC common) on the direction control pin will

produce increasing counts with a counterclockwise rotation of

the shaft.

Ê Rotation is viewed from the end of the encoder shaft.

Gray Code (parallel)

Counterclockwise rotation of the shaft will produce increasing

counts. For increasing counts with a clockwise rotation, use

the Most Significant Bit Complement Pin instead of the Most

Significant Bit Pin. See Electrical Connection table for pin

designation.

ATTENTION: For parallel gray code: connecting the

MSB or MSBC to +DC will result in permanent

damage to the encoder.

Reset Pin

The shaft must be stationary before using the reset function.

Connecting the Reset Pin to +DC will reset Natural Binary and

BCD position value to zero. Connecting the Reset Pin to +DC

will reset Gray Code position value to zero if MSB is used or

to maximum, (e.g., 255, 511, 1023, etc.) if MSBC is used. The

reset function requires a connection to +DC for 0.1 seconds or

longer.

ATTENTION: Activating the Reset Pin results in a

change of position reading. This can cause

unexpected motion which could result in damage to

the product, equipment, or personal injury.