Rockwell Automation 440G-MT Diagnostic Guard Locking Safety Interlock Switch User Manual

Page 2

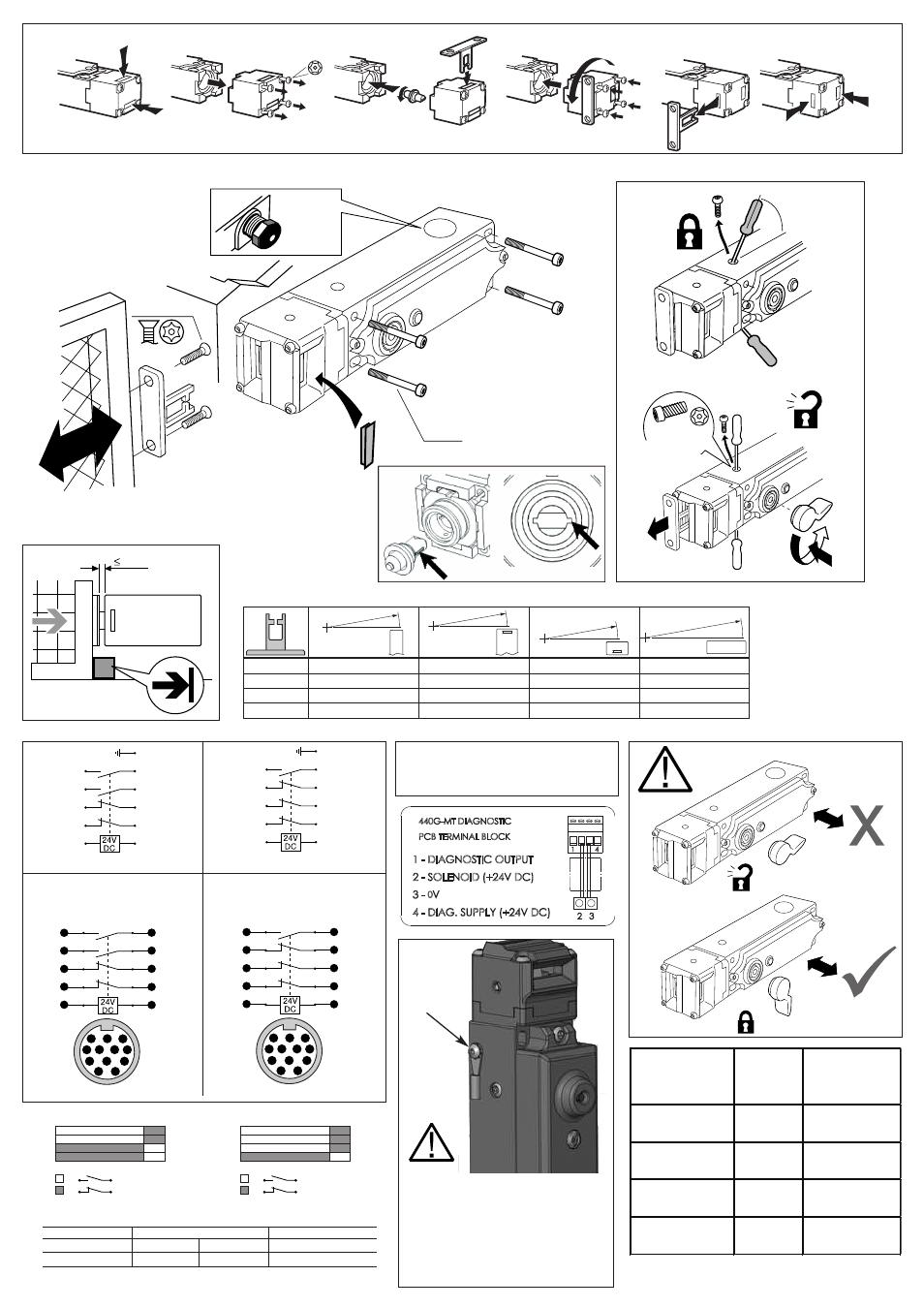

2 x M5 CSK

4 x M5

3 x M20

3 x 1/2" NPT

11

12

21

22

43

44

33

34

A1

A2

440G-MT

11

12

21

22

33

34

43

44

8

9

1

4

6

1

3

7

8

2

5

9

10

10

12

6

11

3

7

2

5

4

A1

A2

440G-MT QD

11

12

21

22

43

44

31

32

A1

A2

440G-MT

11

12

21

22

31

32

43

44

8

9

1

4

6

1

3

7

8

2

5

9

10

10

12

6

11

3

7

2

5

4

A1

A2

440G-MT QD

=

=

3.5mm

11/12

21/22

31/32

43/44

0mm

20

=

=

3.5mm

11/12

21/22

33/34

43/44

0mm

20

90

2 x M4

0.5 N m

(4.4 lb in)

5mm

440G-A27011

440K-A11112

440G-A27143

175mm

175mm

60mm

175mm

175mm

60mm

175mm

175mm

60mm

175mm

175mm

60mm

440K-A17116 175mm

175mm

175mm

175mm

C

A

B

D

1.6 N m (14.2 lb in)

45

Max. Ratings

AC

DC

Applicable

Standards

12-Pin M23

63 V, 6A

63 V, 6A

IEC 61984:2001

Connectors Ratings

Pin 11 - +24V Input (LED power)

Pin 12 - +24V Diagnostic Output

Pin 11 - +24V Input (LED power)

Pin 12 - +24V Diagnostic Output

FOR NON-QD VERSIONS

Terminal 1 to supply 24VDC to for LED power

Terminal 4 provides 24VDC Diagnostic Output Signal

Terminals 2 & 3 to remain the same as QD version

UNIT MUST BE EXTERNALLY GROUNDED

1. Locate grounding screw hole (both sides).

2. Place customer supplied grounding tab ring

(crimped to ground wire) over hole.

3. Place serrated washer over grounding tab.

4. Secure both to body casting with M4 screw,

torque to 1.4 N•m (12.4 lb•in).

5. Attach ground wire to chassis ground.

Ac tua tor &

sole noid

sta tus

LED

sta tus

Dia gnostic

output

sta tus

A c tu a to r o u t &

so le n o id O F F

F la sh in g

re d

+ 2 4 V D C

A c tu a to r o u t &

so le n o id O N

S o lid re d

+ 2 4 V D C

A c tu a to r in &

so le n o id O F F

S o lid

g re e n

0 V

A c tu a to r in &

so le n o id O N

S o lid

a m b e r

0 V