Rockwell Automation 140U Q, M Frame CB Drilling and Assembling Rotary Handle Mechanism User Manual

Rockwell Automation Equipment

Q and M-Frame Circuit Breakers

Instruction Leaflet for Drilling and Assembling

Rotary Handle Mechanism

DO NOT ATTEMPT TO INSTALL OR PERFORM

MAINTENANCE ON EQUIPMENT WHILE IT IS ENER-

GIZED. DEATH, SEVERE PERSONAL INJURY, OR

SUBSTANTIAL PROPERTY DAMAGE CAN RESULT

FROM CONTACT WITH ENERGIZED EQUIPMENT.

ALWAYS VERIFY THAT NO VOLTAGE IS PRESENT

BEFORE PROCEEDING WITH THE TASK, AND

ALWAYS FOLLOW GENERALLY ACCEPTED SAFE-

TY PROCEDURES.

THE ALLEN-BRADLEY CORPORATION IS NOT

LIABLE FOR THE MISAPPLICATION OR MISIN-

STALLATION OF ITS PRODUCTS.

The user is cautioned to observe all recommendations,

warnings and cautions relating to the safety of person-

nel and equipment as well as all general local health

and safety laws, codes and procedures.

The recommendations and information contained herein

are based on Allen-Bradley's experience and judg-

ment, but should not be considered to be all-inclusive or

covering every application or circumstance which may

arise. If any questions arise, contact Allen-Bradley for

further information or instructions.

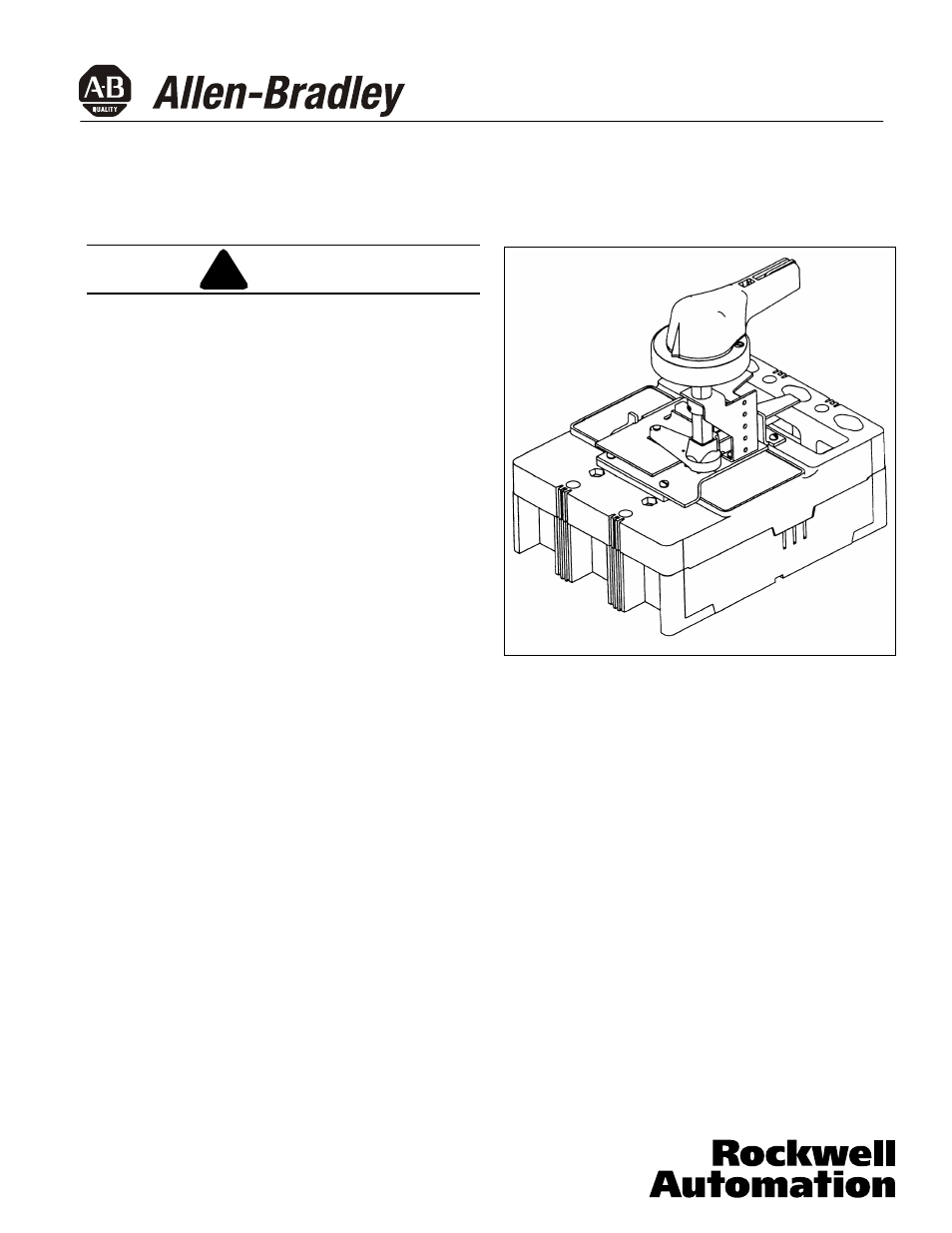

1-0 DESCRIPTION

The Allen-Bradley general purpose rotary handle

mechanism is suitable for use with NEMA 1, 3R, 12 and

4, 4x fabricated enclosures. For NEMA 4 and 4x enclo-

sures the rotary handle is labeled and gasketed for these

applications. It is designed for use with

Q-Frame and M-Frame Circuit Breakers, Molded Case

Switches and HMCP’s up to 800 amps (Figure 1-1).

Required for a standard application are the operating

handle, shaft, and mechanism.

The rotary handle mechanism is Underwriters

Laboratories, Inc. listed for field installation.

The operating handle has been designed to meet NFPA

79 requirements. It may be mounted in either the horizon-

tal or vertical direction. The handle was ergonomically

designed with extra clearance for a "gloved hand" to

!

WARNING

operate. It may be padlocked in the OFF position utilizing

3 padlocks (.312 Max).

The standard label in the operating handle indicates ON/

Tripped/OFF/Open/Reset. To fulfill international require-

ments, an alternate handle may be ordered which indi-

cates (1)/Tripped/(O)/Open/Reset.

To meet the various enclosure depths, four variable depth

shafts are offered (6", 12", 16", and 24"). Each shaft

includes a support brace to ensure proper alignment. In

addition, the 16" and 24" extra long shafts include an

adjustable support bracket.

The standard mechanism located on the breaker does

include means for internally locking the breaker in the

"OFF" position with up to 3 padlocks each with a maxi-

mum diameter of .312".

As an option, an auxiliary switch is offered so that the

control panel builder may electrically indicate the status of

the breaker. This accessory would be mounted on the

mechanism and comes with 24" pigtail leads.

Figure 1-1 Handle Mechanism Assembly (Q-Frame

Shown

40752-073(1)

Effective 6/02

Bul. 140U