Wiring diagrams, Approximate dimensions [mm (in.), Mounting space – Rockwell Automation 871F Proximity Sensors Installation Instructions User Manual

Page 2: Conduit style 1/2 inch npt, Conduit style pg13.5

PN-131512

10000222192 Ver 00

November 2011

Printed in USA

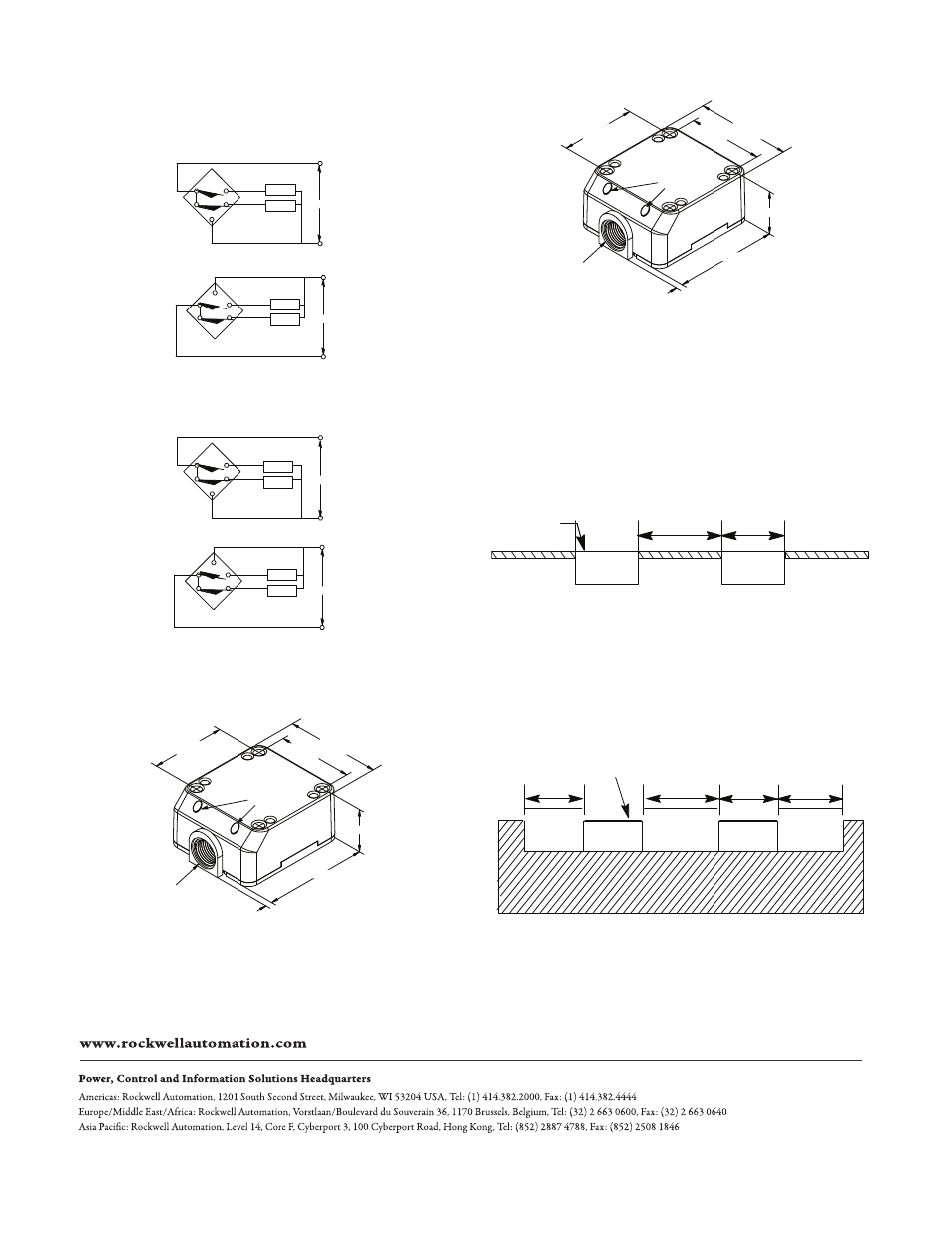

Wiring Diagrams

Conduit Style 1/2 inch NPT

Conduit Style PG13.5

Approximate Dimensions [mm (in.)]

Conduit Style 1/2 inch NPT

Suggested mounting: M5 or SAE#10 cap screw should be

used with a split lock washer to install the unit.

Complementary Normally Open and Normally Closed Outputs

PNP (Sourcing)

NPN (Sinking)

+

-

T4

T1

T5

T2

N.O.

+

-

N.C.

+

-

Load

Load

10…30V DC

+

-

T4

T2

T5

T1

N.O. +

-

N.C. +

-

10…30V DC

Load

Load

Complementary Normally Open and Normally Closed Outputs

PNP (Sourcing)

NPN (Sinking)

+

-

T4

T1

T5

T2

N.O.

+

-

N.C.

+

-

10…30V DC

Load

Load

+

-

T4

T2

T5

T1

N.O. +

-

N.C. +

-

10…30V DC

Load

Load

LEDs

65.0

(2.56)

44.0 (1.57)

83.0

(3.27)

65.0

(2.56)

6.0

(0.24)

94.0 (3.70)

Conduit opening

1/2 inch internal

thread

Conduit Style PG13.5

Mounting Space

Spacing Between Shielded Sensors (flush-

mountable) and Nearby Metal Surfaces

Shielded proximity sensors allow the electro-magnetic field to

be concentrated to the front of the sensor face. Shielded

construction allows the proximity to be mounted flush in

surrounding metal without causing a false trigger.

Flat Pack Style (871F)

Spacing Between Unshielded Sensors (nonflush-

mountable) and Nearby Metal Surfaces

Longer sensing distances can be obtained by using an

unshielded sensor. Unshielded proximity sensors require a

metal-free zone around the sensing face. Metal immediately

opposite the sensing face should be no closer than three

times the rated nominal sensing distance of the sensor.

Flat Pack Style (871F)

LEDs

44.0 (1.57)

94.0 (3.70)

6.0

(0.24)

83.0

(3.27)

65.0

(2.56)

65.0

(2.56)

Conduit opening

PG13.5 internal

thread

Active Face

d

d

d

d

d

4d

Active Face