Sensing/misalignment curve typical wiring diagram, Diagnostic, Sensaguard – Rockwell Automation 440N SensaGuard Rectangular Flat Pack Unique Coded Installation Instructions User Manual

Page 5: Installation instructions 5

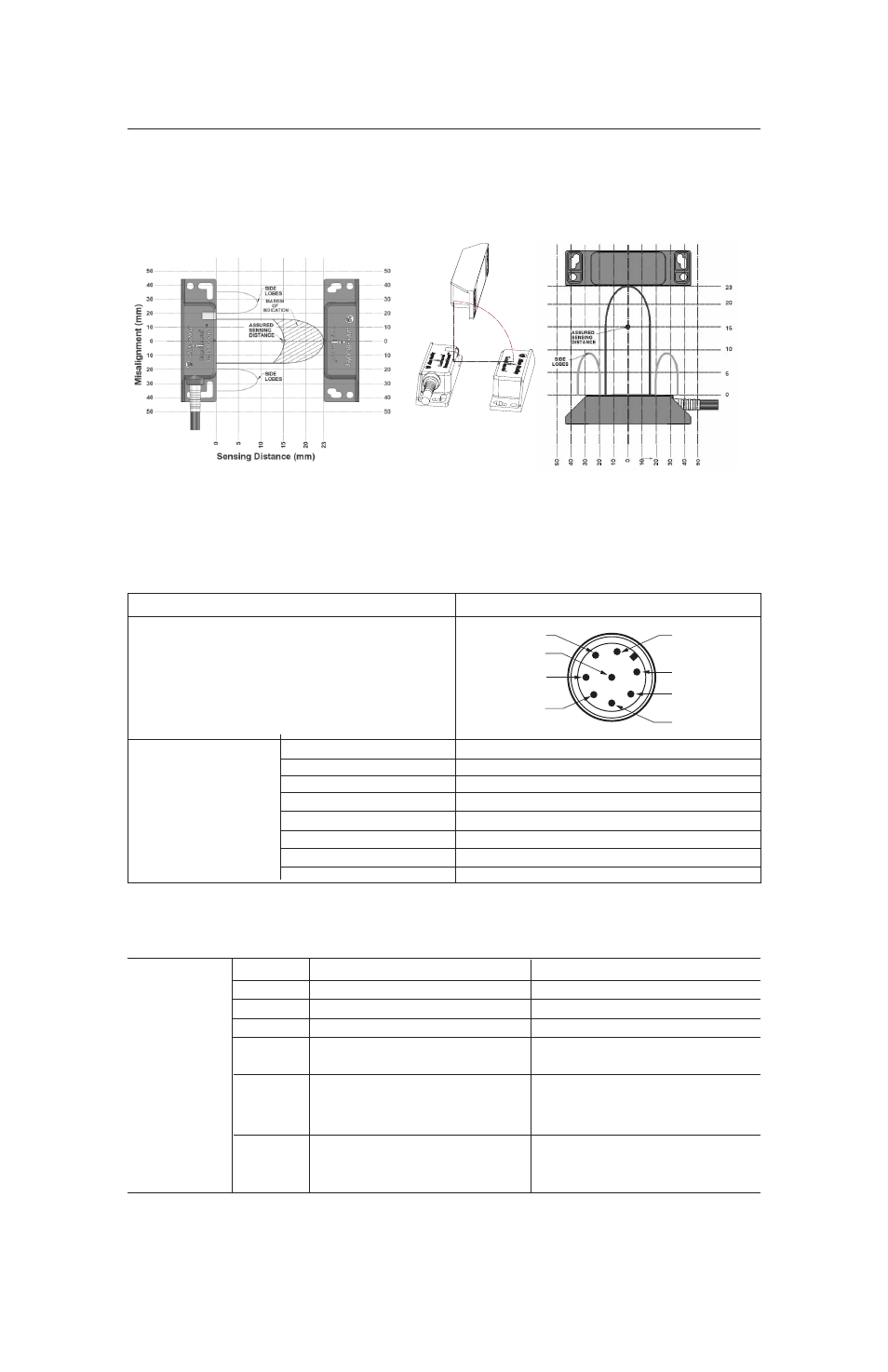

Sensing/Misalignment Curve

Typical Wiring Diagram

Description

Plastic

8-Pin Micro (M12)

Grey

Safety A

Red

Safety A+

Pink

Safety B

8-Pin Cordset

Yellow

Safety B+

889D-F8AB-*

White

Aux A

or cable version

Brown

24V DC+

Blue

Gnd

Green

N/A

* Replace symbol with 2 (2m), 5 (5m) or 10 (10m) for standard cable lengths.

Diagnostic

Unit Indicators (per IEC 60073)

State

Status

Troubleshooting

Off

Not Powered

NA

Status/Diag

Red

Not Safe, OSSD not active

NA

LED

Green

Safe, OSSD active

NA

Green flash

Power up test or OSSD

Check 24V DC or OSSD inputs

inputs not valid

(yellow and red wire)

Red Flash

1 Hz Flash Recoverable Fault

Recoverable fault —check OSSD

4 Hz Flash Non-recoverable Fault

outputs are not shorted to GND,

24V DC or each other. Cycle power.

Amber

1 Hz Flash margin indicator

Sensor is reaching max. sensing

Flash

safe, OSSD active

distance; re-align sensor

with actuator

PN-46047 10000054881 Ver 00 October 2009

SensaGuard

TM

Installation Instructions 5

2-24V DC+

1-Aux A

7-0V

6-Safety B

3-N/A

8-Safety A+

4-Safety B+

5-Safety A

Note: Refer to Technical Specifications for Certification information and ratings.

Sensinng Distance (mm)

Misalignment (mm)

Note: There must be a minimum spacing of 9mm (0.35”) if the actuator and sensor face approaches

laterally.This will prevent false triggering due to the side lobes areas.