Rockwell Automation 25B PowerFlex 520-Series Incremental Encoder Input User Manual

Page 2

PowerFlex 525 Incremental Encoder Input

Publication 520-IN009C-EN-P - July 2014

Supersedes Publication 520-IN009B-EN-P - September 2013

Copyright © 2014 Rockwell Automation, Inc. All rights reserved.

Allen-Bradley, Rockwell Software, Rockwell Automation, PowerFlex, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

U.S. Allen-Bradley Drives Technical Support - Tel: (1) 262.512.8176, Fax: (1) 262.512.2222, E-mail: [email protected]

Online:

+V

Cm

B-

B

A-

A

12V

5V

5

6

No. Signal

Description

A

Encoder A

Single channel, pulse train or

quadrature A input.

A-

Encoder A (NOT)

B

Encoder B

Quadrature B input.

B-

Encoder B (NOT)

Cm Power Return

Internal power source 250 mA

(isolated).

+V 5...12V Power

(1)

(1) If Encoder requires 24V power, it must be supplied by an

external power source.

Output

DIP switch selects 12 or 5 volt

power supplied at terminals

“+V” and “Cm” for the encoder.

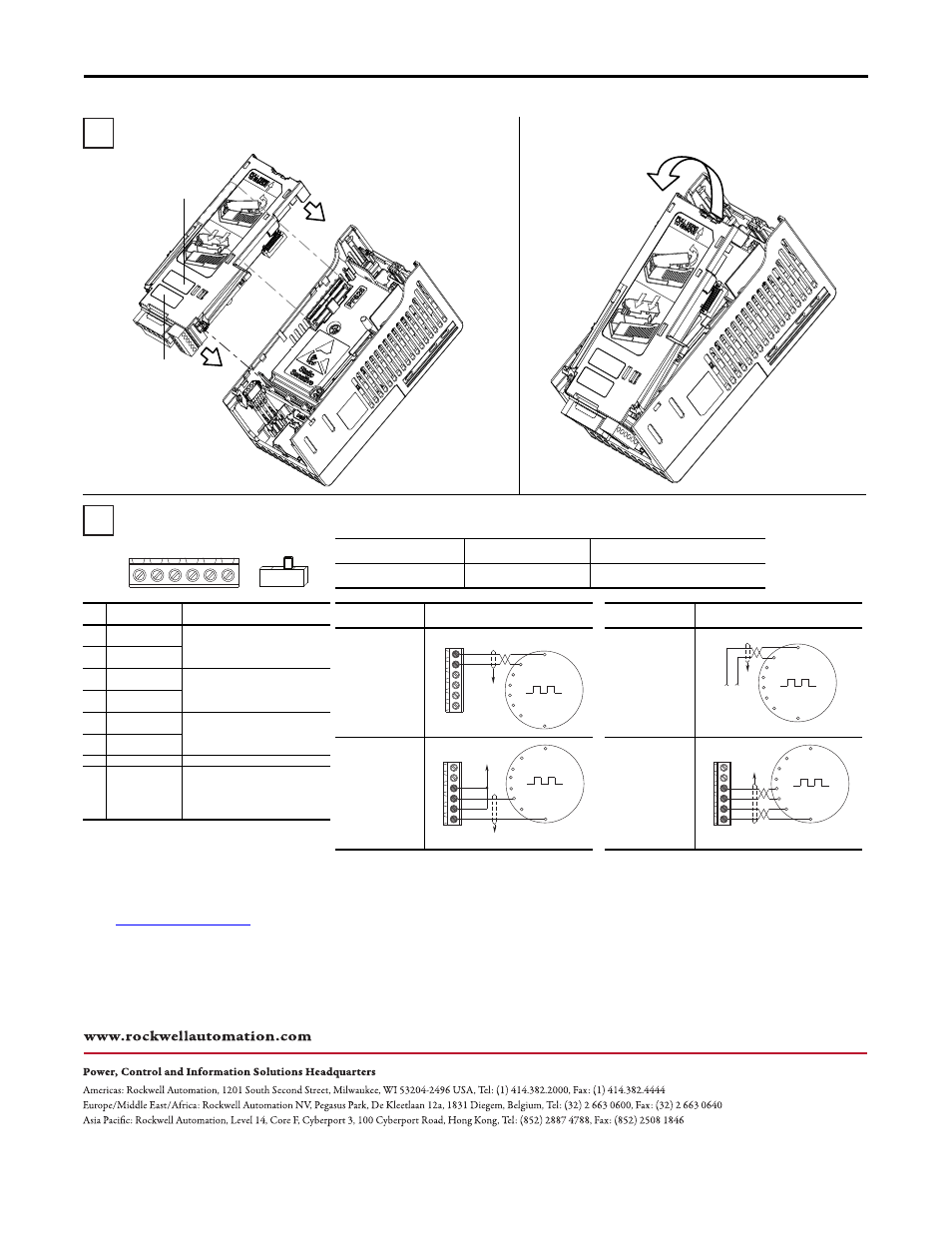

I/O

Connection Example

I/O

Connection Example

Encoder Power

– Internal Drive

Power

Internal (drive)

12V DC, 250mA

Encoder Power

– External

Power Source

Encoder Signal

– Single-Ended,

Dual Channel

Encoder Signal

– Differential,

Dual Channel

Common

+12V DC

(250 mA)

A

A-

B

B-

Cm

+V

to SHLD

+

Common

External

Power

Supply

to

SHLD

A NOT

A

B

B NOT

to SHLD

to Power Supply

Common

A

A-

B

B-

Cm

+V

to SHLD

A NOT

B

A

B NOT

A

A-

B

B-

Cm

+V

Wiring the Incremental Encoder

Attach the Control Module Back Cover

How to Remove the Control Module Back Cover if Required

Maximum Wire Size

Minimum Wire Size

Torque

2.08 mm

2

(14 AWG)

0.08 mm

2

(28 AWG)

0.18...0.22 Nm (1.56...1.9 lb-in)

Incremental Encoder Input with optional

25-COMM-D DeviceNet adapter shown

Incremental Encoder Input

label (pre-attached)

Space for optional

communication adapter label