Installation instructions – Rockwell Automation 871P Inductive Proximity Sensor User Manual

Page 2

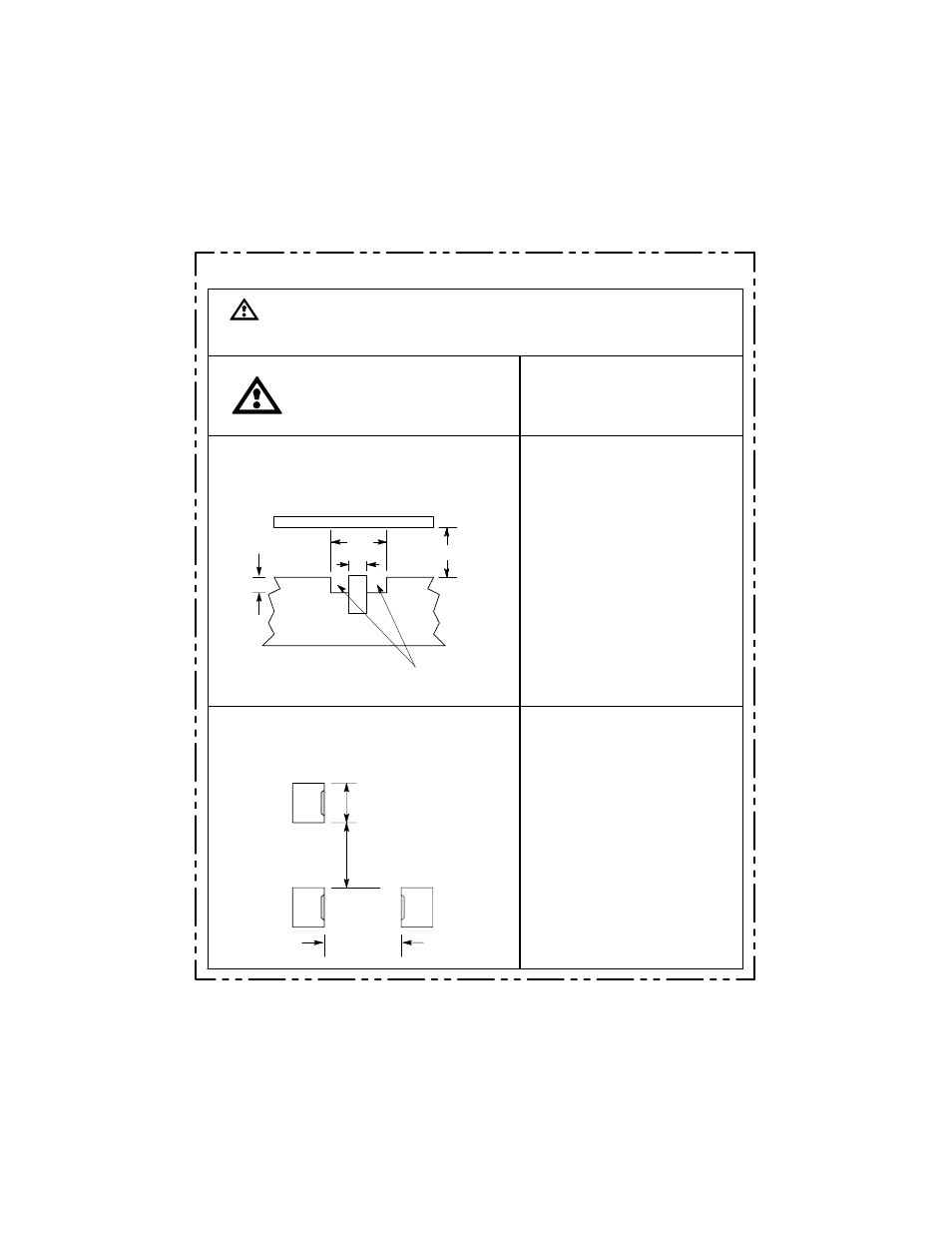

EFFECTS OF NEARBY METAL SURFACES

SPACING BETWEEN SENSORS

WARNING: Do not let METAL objects

that are not to be sensed come within

three times the sensing distance of this

device. Unintended process activation

may result in a hazardous condition.

CAUTION; Solid state devices can be susceptible to radio frequency (RF) interference, depending on the

frequency of the transmitting source. If RF transmitting equipment is to be used in the vicinity of the solid

state devices, thorough testing should be performed to assure that the transmitter operation is restricted

to a safe operating distance from the control equipment and wiring.

INSTALLATION INSTRUCTIONS

SENSING DISTANCE

CORRECTION FACTORS

The standard target is a square of mild steel

(ST37), 1mm thick. The side of the square is

equal to the diameter of the sensor. Targets

smaller than standard size may shorten the

sensing distance. Targets larger than

standard may lengthen the sensing distance.

To determine the sensing distance

for materials other than the standard

mild steel, multiply the sensing

distance by the factor given below:

SERIES CONNECTED SWITCHES

PARALLEL CONNECTED SWITCHES

When connected in series, the operating

load voltage must be less than or equal to

the minimum supply voltage, minus the

voltage drops across the proximity switches

connected in series. The load will energize

when the connected outputs of all proximity

switches are energized.

To determine the maximum number of

switches for an application, the sum of the

maximum OFF-state currents of the

switches connected in parallel must be less

than the maximum OFF-state current of the

load device. The load will be energized when

the output of any proximity switch energizes.

NOTE: Parallel operation of switches does

not provide higher load current capability.

IMPORTANT: Save these instructions for

future use. For additional information and

proper operating guidance, refer to the

Allen-Bradley Proximity Catalog 871-1.2 or

the product data sheet.

When installing side by side, the minimum spacing

distance should be maintained. When mounting face

to face, use two times the diameter.

Metals immediately opposite the sensing face

should be no closer than three times the rated

operating distance of the sensor.

133–551(C)

ЙЙЙЙЙЙЙ

ЙЙЙЙЙЙЙ

ЙЙЙЙЙЙЙ

ЙЙЙЙЙЙЙ

3 Sn

ЙЙЙ

ЙЙЙ

ЙЙЙ

ЙЙЙ

≥

3

d

ЙЙЙЙЙЙЙЙ

ЙЙЙЙЙЙЙЙ

d

25mm

Sn = nominal sensing distance

METAL FREE

ZONE

d

2 x d

4 x d

Steel

1.0

. . . . . . . . . . . . . . . . .

Stainless Steel

0.7 to 0.8

. . . . . . . . .

Brass

0.4 to 0.5

. . . . . . . . . . . . . . . . .

Aluminum

0.3 to 0.4

. . . . . . . . . . . . .

Copper

0.3 to 0.4

. . . . . . . . . . . . . . .