Rockwell Automation 845GM Size 20 Absolete Encoder Installation Instructions User Manual

Rockwell Automation Equipment

Installation Instructions

Size 20 Absolute Encoder, Bulletin 845GM-NXC8024

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

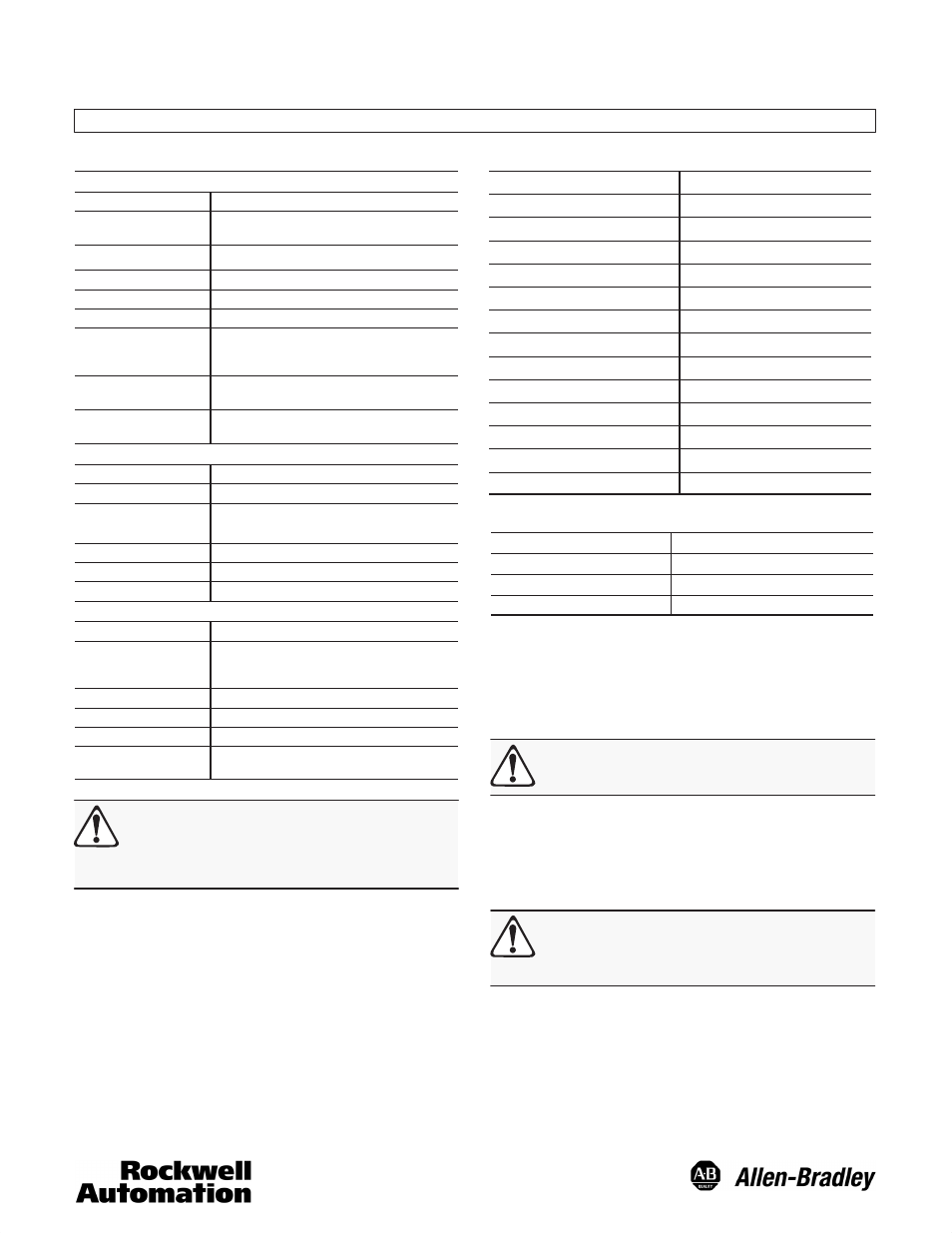

Specifications

Electrical

Code Format

Gray Code

Resolution

Counts per Rev. (CPR)

256 CPR (8 bit)

Accuracy

"1 bit

Requency Response

16K words/sec

Power Requirements

8-24V DC @ 150mA maximum

Output Drive Capability

16mAĊNPN Open Collector

Output Logic

High True

Logic 0" = 0.0 to 0.6V DC

Logic 1" = 24V DC maximum (Open Collector)

Direction Control

Field selectable for increasing counts

(CW or CCW)

Reset

Reset position value to zero. Only with shaft staĆ

tionary.

Mechanical

Starting Torque

3.5in-oz. Typical [0.025 NDm]

Running Torque

3.5in-oz. Typical [0.025 NDm]

Shaft Loading

Axial 40lbs [178N]

Radial 40lbs [178N]

Shaft Size

9.517mm (3/8in) w/flat

Moment of Inertia

0.30oz-in

2

(54gcm

2

) maximum

Slew Sped

5000RPM

Environmental

Housing

NEMA Type 4, 13; IP66

Temperature

0°C to +85°C (+32°F to +185°F)ĊOperating

-20°C to +85°C (-4°F to +185°F)ĊMax Working

-40°C to +100°C (-40°F to +212°F)ĊStorage

Humidity

90%, Noncondensing

Shock

50g (11ms duration)

Vibration

20g (58-150Hz), 1.5mm displacement (10-58Hz)

Appoximate

Shipping Weight

1lb (0.45kg)

ATTENTION: The shielded cables, output devices,

and power supplies must be properly grounded. All

National Electric Code and applicable local codes

and ordinances must be observed when wiring the

system.

Electrical Connections

Wire Color

Function

Black

DC Common

Red

+DC

White

Reset to Zero

Green

MSBC

Orange

Bit 0

Blue

Bit 1

Brown

Bit 2

Yellow

Bit 3

Violet

Bit 4

Gray

Bit 5

Pink

Bit 6

Tan

Bit 7

Shield

Not Connected

Accessories

Description

Part Number

High Performance Flexible Coupling

845-FC-*-*

Measuring Wheels

845-MW-A-*

Servo Clamps

845-SC

*See Sensors catalog for selection.

Direction Control

Ê

Counterclockwise rotation of the shaft will produce increasing

counts. For increasing counts with a clockwise rotation, use

the Most Significant Bit Complement instead of the Most

Significant Bit. See Electrical Connection table for wire

designation.

ATTENTION: For parallel gray code: connecting the

MSB or MSBC to +DC will result in permanent

damage to the encoder.

Reset Pin

The shaft must be stationary before using the reset function.

Connecting the Reset Wire to +DC will reset Gray Code

position value to maximum (e.g., 255) if MSBC is used, to

zero if MSB is used. The reset function requires a connection

to +DC for 0.1 seconds or longer.

ATTENTION: Activating the Reset results in a

change of position reading. This can cause

unexpected motion which could result in damage to

the product, equipment, or personal injury.

Ê Rotation is viewed from the end of the encoder shaft.