Operating current adjustment, Series b relay or series b dashpot, With series b fluid – Rockwell Automation 810 5.0: Inverse Time Current Relays User Manual

Page 2: With series a fluid, Series a relay or series a dashpot

OPERATING CURRENT ADJUSTMENT

- stamped on the nameplate. After the

(Not necessary if factory set to user’s core and dashpot assembly is removed,

specified value). The minimum operat- the core is turned up or down on the

ing current (100% on the time-current piston’s threaded stem till the line cor-

characteristics graph) is adjusted by responding to the desired operating cur-

changing the vertical position of the core rent is in line with the top edge of the

within the operating coil. Calibration dashpot Currents other than those indi-

lines on the core correspond to current cated by the lines are possible by

and interpolation.

NOTE:

If electrical tests are made of cur-

rent calibrations they should be done

without fluid in the dashpot (clean

and dry.)

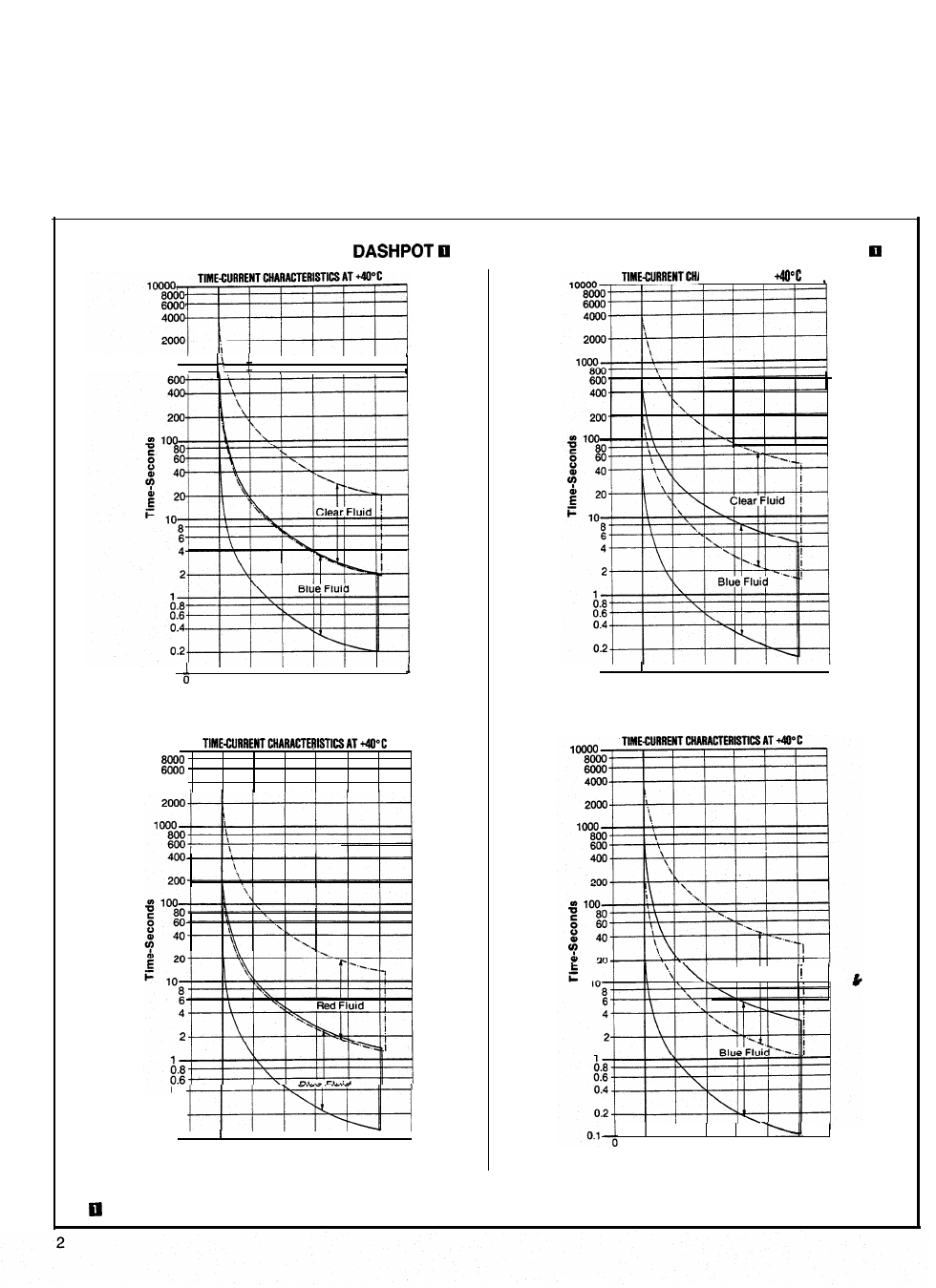

SERIES B RELAY OR SERIES B

SERIES A RELAY OR SERIES A DASHPOT

ARACTERISTIC AT

000

I

I I

800

1

i

I

I

I

0.1

I

I I

I

0 100

Percent

of Minimum Operating Current

200 300 400 500

600

0.1

I I

I

I

100 2 0 0 3 0 0 400 5 0 0 6 0 0

Percent of Minimum Operating Current

With Series B Fluid

With Series B Fluid

10000

4000

Red Fluid

i

\ .

0.2

0.1

I

I

I

I

I

0 100 200 300 400 500 600

Percent of Minimum Operating Current

With Series A Fluid I

With Series A Fluid

100 2 0 0 3 0 0 4 0 0 5 0 0 6 0 0

Percent of Minimum Operating Current

Series B Dashpots are identified by the rib along the side of the dashpot. Refer to photo on back page. Series A

do not have this rib.