Rockwell Automation 842A Absolute Encoder User Manual

Rockwell Automation Equipment

Installation Instructions

Bulletin 842A Absolute Encoders

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

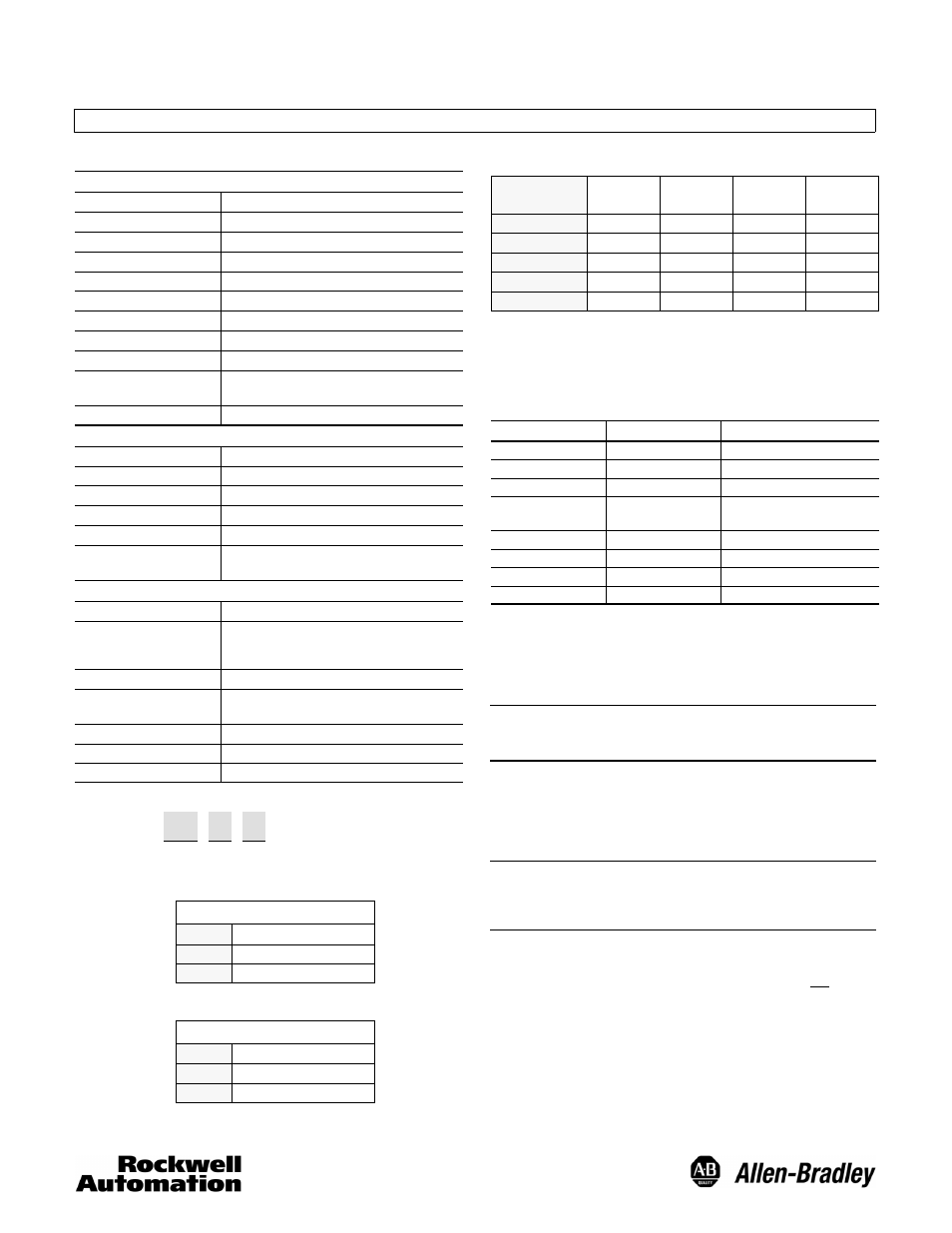

Specifications

Electrical

Code Format

Gray or Natural Binary

Code Direction

CW or CCW

Symmetry

40% to 60%

Operating Voltage

10–32V DC

Power Requirements

150mA @ 5V (no load)

Max # of Steps/Revolution

8192

Max # of Revolutions

8192

Position Forming Time

0.5msec

Delay on Power Up

1050msec

Clock +, Clock - , Data +,

Data -

Synchronous Serial Interface (SSI) RS--422

CW/CCW

“L” active (L = 0--0.9V, H = 1.9 – 24V))

Mechanical

Angular Acceleration

5 x 10

5

radians/sec

2

Moment of Inertia

5 x 10

--4

oz-in-sec

2

(35 gcm

2

)

Maximum Working Speed

6000 RPM at max shaft loading

Maximum Operating Speed

12,000 RPM

Starting Torque

3.5oz in (2.5 Ncm)

Shaft Loading

Axial 11lb (50N)

Radial 67lb (300N)

Environmental

Housing

Aluminum

Temperature

--20_C to 85_C (--4_F to 185_F) operating

--40_C to 100_C (--40_F to 212_F) max. working

--40_C to 125_C (--40_F to 257_F) storage

Humidity

98% noncondensing

Protection

NEMA Type 4, 13, IP67 (IEC 529): static shaft

NEMA Type 4, 13, IP66 (IEC 529): moving shaft

Shock

100g/6msec

Vibration

20g/58--2000Hz, 1.5mm displacement (10--58Hz)

Approximate Weight

0.5kg (18oz)

Selection

842A — 31

G B

a

b c

a

Code Type

Code

Description

31

36mm Pilot, 10mm Shaft

56

50mm Pilot, 6mm Shaft

b

Code Type

Code

Description

G

Gray Code

N

Natural Binary

c

A-B

Code

Pulses

Per Rev.

SSI Bits

MSB- LSB

No. of

Revs.

SSI Bits

MSB- LSB

A

8192

12--24

2048

1--11

B

4096

13--24

4096

1--12

C

2048

14--24

8192

1--13

D

4096

13--24

512

4--12

E

4096

13--24

256

5--12

Electrical Connections

The 842A comes with an M23 connector. The mating

connector, 845--12P, or pre-wired cable and connector

assembly 845--CA--G--* must be ordered separately. See

Encoder Accessories in the Sensors catalog.

Function

Pin Number

Description

DC Return

1

Ground

Data +

2

SSI

Clock +

3

SSI

DC + Input

8

10--32V DC

150mA no load

Reset

9

Data --

10

SSI

Clock --

11

SSI

CW/CCW

12

See below

Reset to zero is enabled when Pin 9 is momentarily connected to DC+ Input.

When pin 12 is connected to DC + (or left floating), the 842A will count UP when

the shaft is turned CW when looking at the shaft. When pin 12 is connected to DC

return, the 842A will count UP when the shaft is turned in the CCW direction when

looking at the shaft.

IMPORTANT: Wiring must be in accordance with the

National Electric Code and applicable local

codes and ordinances.

Mounting Instructions

1. Be sure to select the proper size flexible coupling clamp to

mate to the encoder shaft, e.g., 845--FC--*--*. See

Encoder Accessories in Sensor catalog.

IMPORTANT: Do not rigidly connect the encoder shaft to

the machine; this will cause premature

failure of the encoder or machine bearings.

Always use a flexible coupling.

2. Use the dimension drawings to determine the encoder

mounting hole locations.

3. Slide the flexible coupling onto the shaft, but do not tighten

the set screws.

4. Mount the encoder and tighten with three size M4

mounting screws (not supplied).

5. Center the flexible coupling and tighten the set screws.

6. Rotate the machine slowly and verify that the flexible

coupling is not deforming beyond specifications.

7. Align machine to its mechanical zero or home position.

Remove slotted cover located on the back of the encoder

and press the Reset button to make the encoder count

zero. Replace cover.