Rockwell Automation 802T 802T 4-Circuit Direct Opening Action Limit Switch User Manual

Page 2

S

Grounding of switch should be achieved per National

Electric Code (NFPA 70) requirements. Grounding terminal

is located in the terminal block housing.

S

Arrange control wiring according to terminal markings.

S

Tighten terminal screws according to specifications.

S

Only use insulated connectors.

Important: Pay close attention to the terminal

numbering on the terminal block when

wiring this switch. Terminals 1 and 2 or 5

and 6 are normally open contacts.

Terminals 3 and 4 or 7 and 8 are normally

closed contacts.

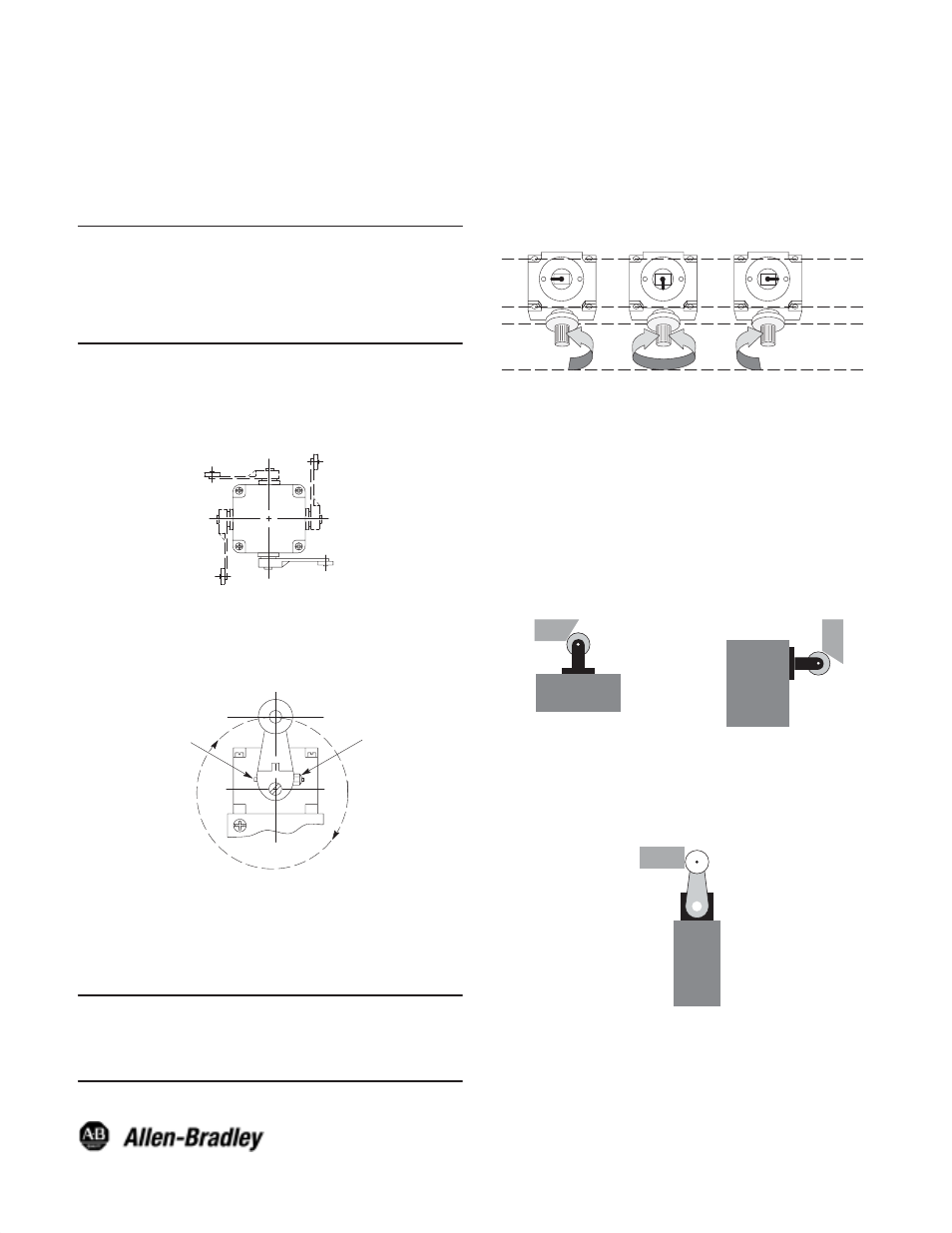

Actuator Head Positioning

The actuator head may be placed in any of four positions on

the switch body. Loosen the four captive screws. Place the

head in the desired position and securely retighten the four

screws (see figure below).

Lever Positioning

The lever on rotary actuated devices is adjustable to any

position through 360

_

around the shaft. Loosen the nut, move

the lever to the desired position and securely retighten the nut

(see figure below).

Lock Pin

Nut

Changing Direction of Actuation

The switch action of lever operated limit switches may be

adjusted to operate with either a clockwise, a

counterclockwise or both directions movement of the shaft.

To change the actuation direction, follow the steps below:

Important: This procedure must be performed in a

clean environment to avoid the

introduction of foreign material into the

operating mechanism.

Step 1: Loosen the four head mounting screws and remove

the operating head from the switch body.

Step 2: Locate the plunger on the underside of the operating

head.

Step 3: Pull the plunger outward and rotate it in steps of 90

_

to provide the operating mode desired. The

respective settings are shown in the figure below.

CCW Only

CW Only

CW & CCW

Plunger

Setting

Actuation

Required

Step 4: Make sure the plunger is pushed back inward and

the “O” ring is properly seated before the operating

head is reattached to the switch body.

Step 5: Securely retighten the operating head mounting

screws.

Step 6: Check for the desired actuation mode.

Methods of Actuation Examples

802T–KPD

Side Push Roller

30

_

Non-Overtravel Dog

802T–DPD

Top Push Roller

30

_

Non-Overtravel Dog

Vmax = 30ft/min @ actuator

F max = 150 cycles/min

802T–APD

802T–W1A 1.5

I

Long

90

_

Non-Overtravel Dog

Vmax = 30ft/min @ actuator

F max = 150 cycles/min

Publication 75023–092–01(A)

September 2002

Printed in USA