Rockwell Automation 440P Bulletin 440P 2 N.C. Small Metal Safety Position Switches with 4-Pin Male Micro User Manual

Page 2

2

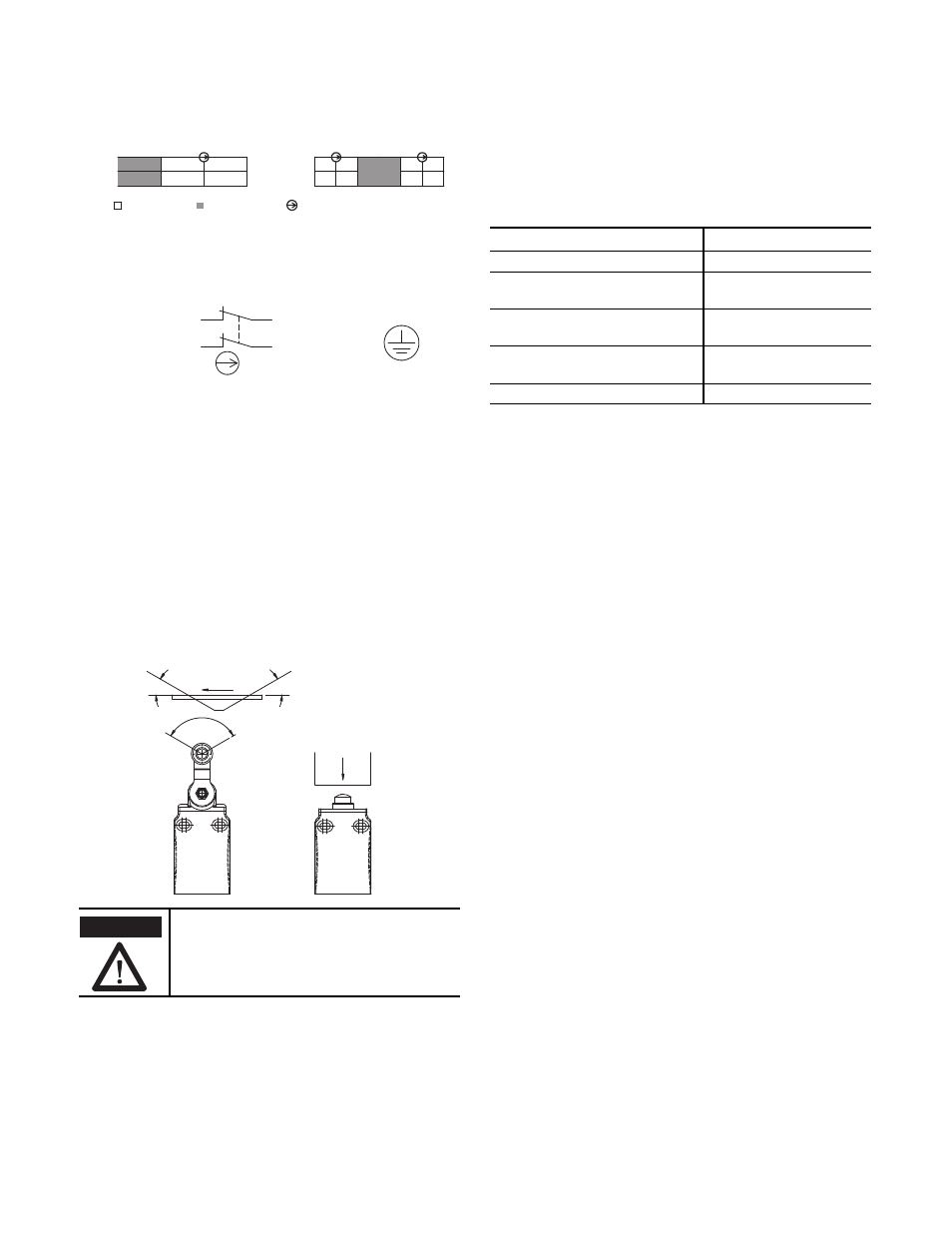

Contact Opening Characteristics

Wiring Diagram

Maintenance

These devices require little maintenance, but routine visual

inspection is recommended to keep foreign debris from

collecting on the exterior actuators and rollers. Removing the

operator head is not recommended as loose internal

components may be lost or improperly re-installed.

Actuation Guidelines

The method of actuation and over travel has significant

influence on the service life of the limit switch. To maximize

the service life, it is recommended to provide an actuator with

a 30° pressure angle and a surface hardness of Rc-45 max.

Under no circumstances must the switch be

actuated beyond the mechanical travel specified.

Serious damage to the device and property could

result.

Open

Closed

Positive Opening Point

Plunger Type

0 mm 1.4 mm 2.6 mm 5.5 mm

11-12

21-22

11-12

21-22

85° 41° 26° 0° 26° 41° 85°

Lever Type

Safety Input 1

Safety Input 2

Zb

Safety Output 1

Safety Output 2

Ground

60°

60°

30°

30°

ATTENTION

Lever Positioning

Some rotary switches are supplied with levers that are

mechanically coupled to the actuating shaft. The lever may be

removed and re-installed for cam tracking adjustment. See

table below for torque recommendations.

Torque Specifications

Location

Torque

3.5 mm Operator Head Phillips Screws

0.8 N•m (7.1 lb•in)

Short and Wide Roller Lever Arm

8 mm Hex Nut

1.0 N•m (8.85 lb•in)

Adjustable Lever Arm

4 mm Allen Head Screw

1.8…2.8 N•m

(15.93…24.78 lb•in)

Adjustable Lever Arm Collar

3 mm Allen Head Screw

3.2 N•m (28.32 lb•in)

12 mm Panel Mount Nut

1.5 N•m (13.28 lb•in)