Rockwell Automation 42GNC_NF_NL_NP_NR_NU SmartSight DeviceNet PHOTOSWITCH Photoelectric Sensors User Manual

Page 3

3

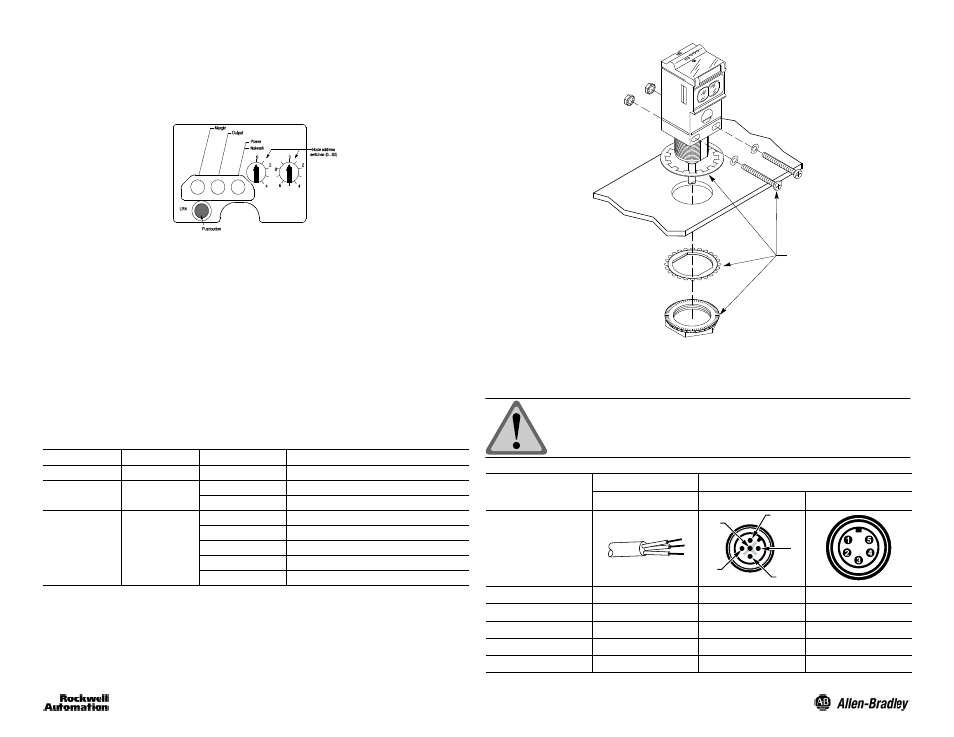

User Interface

Using an instrument screwdriver, open the top cover of the sensor to gain access to the user interface

panel. This panel contains a pushbutton, node-address switches, and LED indicators for configuring and

viewing the sensor’s operation and status. A more complete description of each item is described below.

SmartSightt Sensor—Top View Detail

Node

Address

Pushbutton

A single momentary pushbutton, labeled LRN, is used to “teach” the sensor the application presented to it.

Refer to the Self-Teach in this document for complete instructions on using this feature.

Selector Switches

Two selector switches are provided for setting the sensor node address on the network. Possible addresses

range from 063. The node address may also be set over the network using the RS Networx configuration

tool.

LED Indicators

Three LED indicators are provided to indicate a variety of conditions making it easy for installation and

troubleshooting. The function of each is described in the table below. The LEDs also work together as

indicated on page 5 when used in the self-teach mode.

Table 1. LED Function

Label

Color

State

Status

Output

Yellow

ON

Target detected

Margin

Orange

OFF

Margin < 2.5

ON

Margin 2.5

Network

Red/Green

OFF

Sensor not powered

Green ON Steady

Sensor active and allocated by master

Green Flashing

Sensor active but not allocated by master

Red Flashing

Minor correctable fault (baud rate)

Red ON Steady

Major fault (possible duplicate address)

Note

: LED indicators are used during the Self-Teach operation of the sensor. Refer to the Self-Teach

section for complete instructions on using this feature.

Mounting the Sensor

Securely mount the sensor on a firm, stable, surface or support using one of the many mounting brackets

available from Rockwell Automation/Allen-Bradley. The sensor is supplied with hardware kit #129--130

which contains a plastic mounting nut, lock washer, 2 M5 x 0.8 x 53 screws and nuts. Excessive vibration or

shifting may cause intermittent operation of the sensor.

Hardware Kit

(Supplied)

Wiring the Sensor

Models of SmartSight are available in one of three different connection types as identified in the following

table. Rockwell Automation/Allen-Bradley recommends the use of the 1485R Series of cordsets and

patchcords on the quick-disconnect models.

ATTENTION: All external wiring should conform to the National

Electric Code and all applicable local codes.

Designation

Lead Color

Cordset Pin Assignment

2 m Cable

5-Pin Micro QD

5-Pin Mini QD

5

4

3

1

2

V+

Red

2

2

V--

Black

3

3

CAN +

White

4

4

CAN --

Blue

5

5

Drain

Bare

1

1