Power wiring – Rockwell Automation 20GY PowerFlex 755 with OEM Liquid Cooling Frame 6 and 7 AC Drives User Manual

Page 11

Rockwell Automation Publication 20GY-IN001A-EN-P - June 2011

PowerFlex® 755 with OEM Liquid Cooling Frame 6 and 7 AC Drives

11

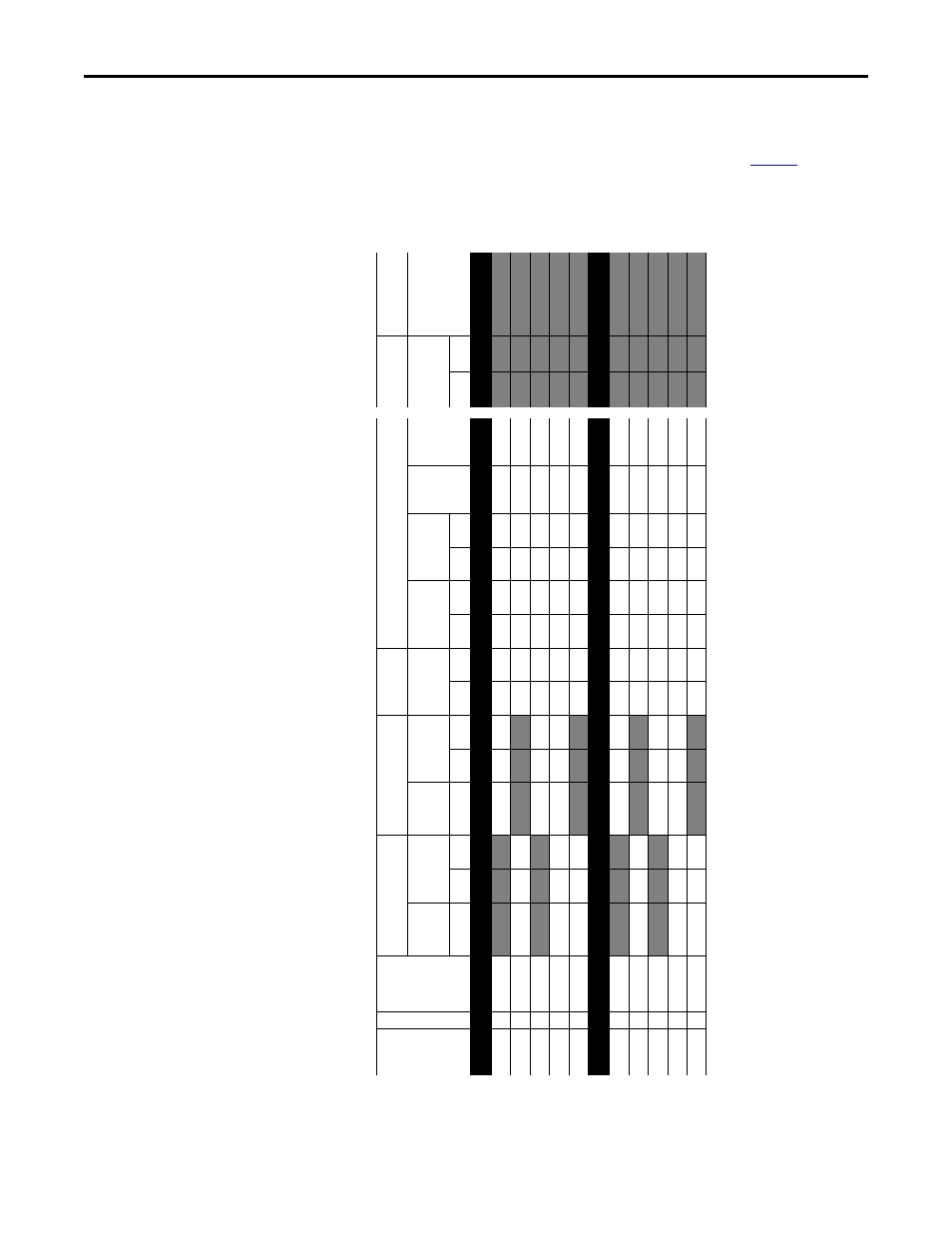

Power Wiring

Refer to the information in the

PowerFlex 750-Series AC Drive Installation

Instructions (publication 750-IN001) to wire power to the PowerFlex 755 with

OEM Liquid Cooling Frame 6 and 7 AC drives. However, see

for the

recommended AC line input protection devices to use instead of the protection

devices listed for the standard, air-cooled PowerFlex 755 Frame 6 and 7 drives in

the

PowerFlex 750-Series AC Drives Technical Data (publication 750-TD001).

Ta

ble

3 - Recom

men

ded AC Inp

u

t Pro

tec

tion

De

vice

s

Appl

ie

d

Rati

ng

(1

)

(1)

“Ap

plie

d Rat

ing”

r

ef

ers

to

the mot

or

that

will

be c

onnec

te

d t

o t

he d

riv

e.

F

or e

xamp

le

, a “

C

367

” d

riv

e ca

n be

used

in Nor

m

al

Du

ty

mode

on a

200

kW mot

or

, or

in Hea

vy D

uty

mode

on

a 16

0 k

W

mot

or

. A

“C

260”

d

riv

e ca

n b

e u

sed

in He

av

y Dut

y

mode

on

a

110

kW

moto

r

with

the s

ame

ra

tings

as

a

“C

205.

”

The

dr

iv

e

can

be

pr

og

ra

mmed

fo

r eit

her

mod

e.

W

ir

ing

and f

uses

c

an be siz

ed bas

ed on th

e pro

gr

am

med mode

. F

or an

y giv

en dr

iv

e cat

alog n

umb

er

, Nor

m

al Dut

y mode pr

ov

ides highe

r co

nti

nu

ous cu

rr

ent

b

ut

s

m

aller

o

ve

rlo

ad cur

rent

wit

h r

espe

ct

to

Hea

vy Dut

y

mo

de

. See pa

ra

met

er

306 [D

uty

R

ating

].

Frame

Conti

n

u

ous

Outp

ut

Amps

Driv

e Siz

ed

F

o

r

Normal

Duty

Drive Size

d

F

o

r

Hea

vy

Duty

Inpu

t

Q

u

antit

ies

A

C

Inpu

t Pr

otection

De

vices

In

pu

t

Q

u

an

ti

ties

DC Input

Pr

otectio

n

Catal

o

g

Number

Ou

tp

ut

Over

lo

ad

Amps

Catalog

Number

Ou

tput

Ov

erlo

ad

Amps

Co

ntinuou

s

A

C

I

npu

t

Du

al Elemen

t

Ti

me

De

la

y

Fu

se

No

n-Ti

me

Dela

y Fu

se

Cir

cui

t

Bre

aker

M

axim

u

m

Size

(4

)

(4)

C

ircu

it Bre

ak

er

- in

ve

rs

e t

ime

br

eak

er

. F

or

US NEC

, min

im

um

siz

e is 125% of

mot

or

FLA.

Ra

ting

s

sh

ow

n ar

e

ma

xim

um.

Mo

tor

Cir

cui

t

P

rotector

(5

)

(5)

R

eco

mmended

Mot

or

circ

uit

pr

ot

ect

or

-

In

st

an

ta

neou

s t

rip

circ

uit br

eak

er

. Th

e

tr

ip set

ting

s

hould be se

t to

the input

cur

re

nt

of

the

d

riv

e an

d

shou

ld

be

s

iz

ed

fo

r

the

c

ont

in

uous

cu

rr

en

t o

f t

he sy

st

em

.

Co

ntinuo

us DC

In

pu

t

No

n-Ti

me De

la

y

Fu

se

x

=

GY

1 m

in

3 s

e

c

1 m

in

3 sec

kV

A

Am

ps

Mi

n

(2

)

(2)

M

in

im

um pr

ot

ect

ion de

vi

ce siz

e is

the lo

w

est

r

at

ed de

vi

ce

th

at su

pplies maxim

um pr

ot

ect

io

n wit

hou

t n

uisa

nce t

rip

ping.

Ma

x

(3

)

(3)

M

axim

um

pr

ote

ct

io

n d

evic

e s

iz

e is

th

e

highes

t r

ated

d

evice

that

supp

lies

d

riv

e pr

ot

ect

ion.

F

or

U

S

NEC

, minim

um s

iz

e is

125

%

of

moto

r FLA.

Rat

in

gs sho

w

n ar

e maxim

um.

Mi

n

(2

)

Ma

x

(3

)

kW

Amps

400 V

o

lt

A

C

In

pu

t

540 V

o

lt D

C

Inp

u

t

110

k

W

6

205

20

x…

C

2

60

30

7.

5

39

0.

0

13

9.

1

2

00.

8

2

75

4

50

2

75

6

00

6

00

4

00

132

k

W

6

260

20x

…C2

60

28

6.0

39

0.0

17

6.

5

2

54.

7

3

25

5

75

3

25

7

50

7

00

4

00

160

k

W

7

302

20

x…

C

3

67

45

3.

0

55

0.

5

20

5.

0

2

95.

9

4

00

6

75

4

00

9

00

9

00

6

00

200

k

W

7

367

20x

…C3

67

40

3.7

55

0.5

20

x…

C

4

77

55

0.

5

68

4.

0

24

9.

1

3

59.

5

4

75

8

00

4

75

1

000

1

100

6

00

270

k

W

7

477

20x

…C4

77

52

4.7

71

5.5

38

8.

5

4

67.

3

6

00

1

000

6

00

1

200

1

200

6

00

480 V

o

lt

A

C

In

pu

t

650 V

o

lt D

C

Inp

u

t

150

Hp

6

186

20

x…

D

2

48

27

9.

0

37

2.

0

14

5.

2

1

74.

6

2

50

4

00

2

50

6

00

5

50

2

50

200

Hp

6

248

20x

…D2

48

27

2.8

37

2.0

19

3.

6

2

32.

8

3

25

5

50

3

25

7

00

7

00

4

00

250

Hp

7

302

20

x…

D

3

61

45

3.

0

54

3.

6

23

5.

7

2

83.

5

4

00

6

75

4

00

9

00

9

00

6

00

300

Hp

7

361

20x

…D3

61

39

7.1

54

1.5

20

x…

D

4

77

54

1.

5

64

9.

8

28

1.

8

3

38.

9

4

75

8

00

4

75

1

000

1

000

6

00

400

Hp

7

477

20x

…D4

77

52

4.7

71

5.5

37

2.

3

4

47.

8

6

00

1

000

6

00

1

200

1

200

6

00

Not

e

s: