Mounting the sensor, Wiring the sensor, Configuring the sensor – Rockwell Automation 42EF RightSight Photoelectric Sensors with Teach Function User Manual

Page 2: Short-circuit protection, Wiring diagrams, Dimensions—mm (inches), Accessories

Publication 75044–124–01(B)

November 2005

Printed in USA

PHOTOSWITCH

R

is a registered trademark of Rockwell Automation.

Visit our web site at www.ab.com.

Mounting the Sensor

Securely mount the sensor on a firm, stable surface or support. A mounting which is subject

to excessive vibration or shifting may cause intermittent operation. Refer to

www.ab.com/sensors for information on vertical and horizontal adjustment as well as fixed

mounting brackets. The sensor is supplied with a single 18mm mounting nut for either nose or

base mounting options.

Wiring the Sensor

The RightSight photoelectric sensor is available in either a 2m (6.5ft) cable or 4Ćpin micro

quick disconnect as identified on page 1. Rockwell Automation recommends the use of the

889D Series of cordsets and patchords for the QD models. All external wiring should

conform to the National Electrical Code and all applicable local codes.

Configuring the Sensor

These versions of the RightSight contain a teach function with pushbutton rather than a

manual adjustment knob for adjusting the sensors sensitivity level. This function allows the

sensor to learn" both a light and a dark condition (background/target) presented to it and

automatically adjusts sensitivity to its optimal level for the application. Follow the steps below

to configure the sensor for your specific application.

1. Ensure that the sensor is securely mounted and wired. The green LED will be illuminated

indicating that power is applied to the sensor.

2. With the sensor pointed at the light condition, press the pushbutton for five seconds and

then release. The green PWR/STAB LED will turn OFF and the orange SET/SCP LED will

turn ON to indicate that the sensor is learning the light condition. When this condition has

been learned, it will then flash prompting the user to present the dark condition.

3. With the sensor pointed at the dark condition, press the pushbutton for five seconds and

then release. The orange SET/SCP LED will turn ON to indicate that the sensor is learning

the dark condition. When this condition has been learned, it will turn OFF and the green

PWR/STAB LED will turn ON. The sensor is now ready for operation.

Note

S

The light condition must be presented first followed by the dark condition. Depending on

the operation, this may be either the background or target.

If there is no background, in the case

of a diffuse sensor, present the target first.

S

A flashing green PWR/STAB LED indicates an unstable application condition (little contrast

between the light and dark conditions). If this occurs, the sensor will provide reliable

detection of a target, but may deteriorate over time due to contamination (dirt/dust).

S

If insufficient contrast is present between both conditions, it may be necessary to skew the

sensor by up to 20_ or change the reflectivity of one of the conditions. For example, when

using a standard diffuse sense mode, painting a reflective background with a nonreflective

finish may help. With fixed focus sensing modes, it may be necessary to use a model with

different light source color to acheive maximum contrast.

Short-Circuit Protection

RightSight photoelectric sensors provide shortĆcircuit protection (SCP) on the output leads.

This feature is intended to protect the sensor from damage in the event that the output load is

shorted to ground. If this condition does occur, the SCP will activate and the orange LED and

green LED will flash until the source of the short is removed. The SCP limits are set to 100mA

over the entire voltage range.

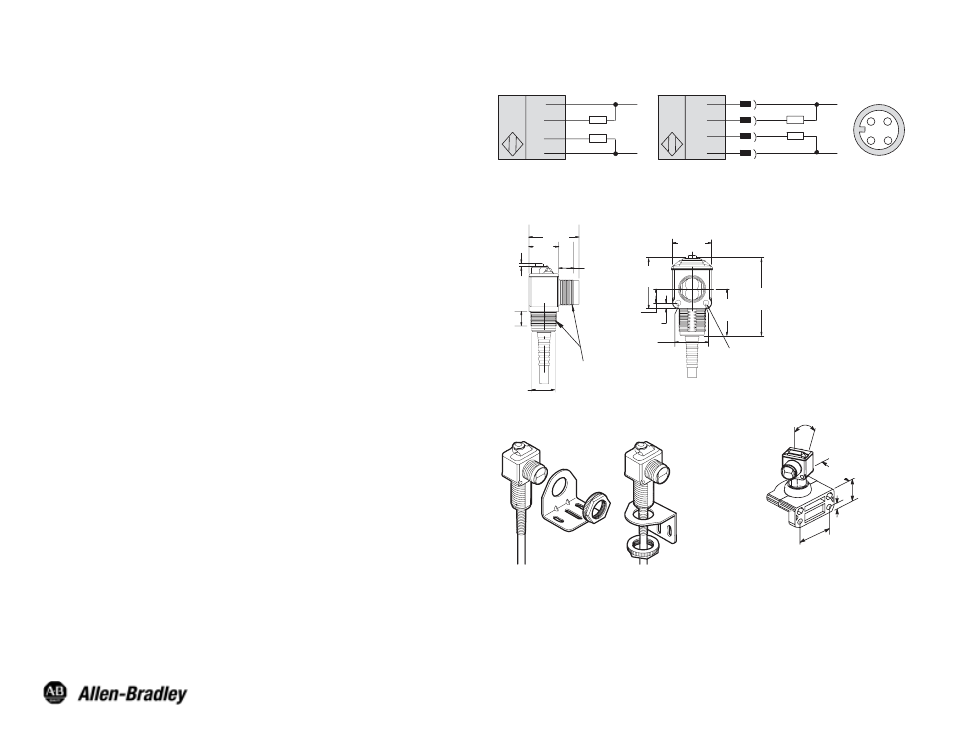

Wiring Diagrams

10.8–30V DC Sensors

Models with Dual NPN and PNP Outputs

Brown

Blue

White

Black

+

–

+

–

1

2

4

3

Cable

QuickĆDisconnect

Brown

White

Black

Blue

1

3

2

4

Load

Load

Load

Load

DC Micro

Note: All wire colors on quick-disconnect models shown refer to Allen-Bradley cordsets.

Dimensions—mm (inches)

10

(0.40)

16.5

(0.65)

10

(0.40)

19

(0.75)

20.5

(0.81)

4

(0.16)

9.6

(0.38)

3.6 (0.145) Diameter

Clearance for #6-32

Screw (2 Places)

M18 X 1.0 Thread

46.7

(1.84)

27.5

(1.08)

27

(1.06)

34.5

(1.36)

1.78

(0.07)

32.7

(1.29)

50.08

(2.0)

28.6

(1.125)

10_Adjustment in

Each Direction

Accessories

Right Angle Bracket #60–2657

Swivel/Tilt Bracket #60–2649

57.15

(2.25)

7.95

(0.31)

Notes

1. Damage may occur to sensor housing if torque above 20in-lb is applied to the 18mm locknut.

2. Optional mounting kit (60–2716) comes with two 75012–025–01, one 75012–097–01 locknut, internal tooth

star washer, and screws/nuts for through-hole mounting.