3mounting, Wiring, Accessories micron conversions – Rockwell Automation 45BRD Analog Laser Sensor User Manual

Page 3

3

Mounting

Securely mount the sensor on a firm, stable surface or support for

reliable operation. A mounting which is subjected to excessive

vibration or shifting may cause intermittent operation. The

following mounting brackets are available for installation

convenience and sensor protection. Once securely mounted, the

sensor can be wired per the attached wiring diagram.

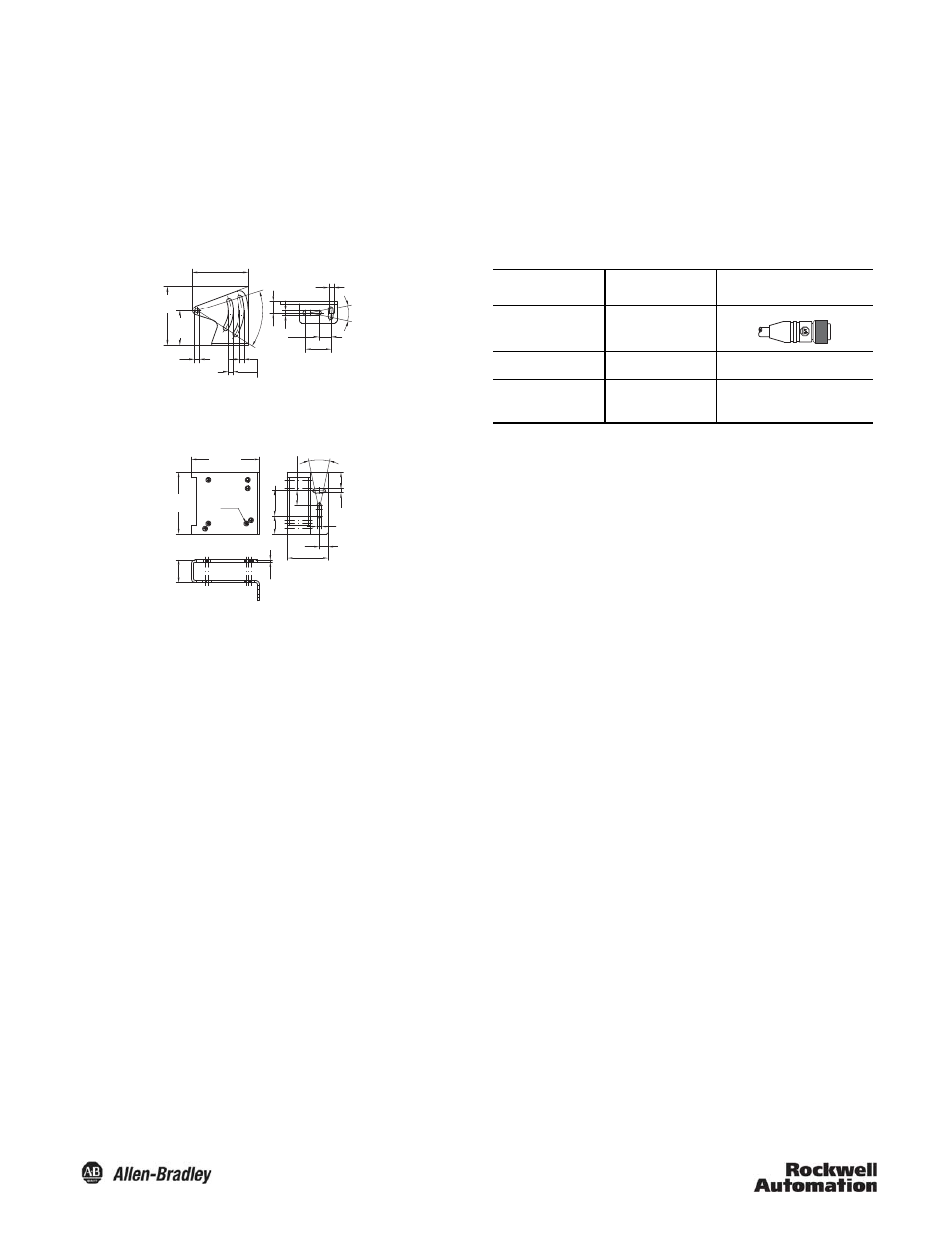

Mounting Bracket Dimensions—mm (inches)

45BPD-BKT1

45BPD-BKT2

Wiring

The 45BRD photoelectric sensor is available with a micro quick-

disconnect for ease of installation and maintenance. The connector

can be rotated up to 270º to accommodate the installation of the

sensor and its associated wiring. Rockwell Automation

recommends the use of the 889 Series of cordsets and patchcords

for quick disconnect model sensors. All external wiring should

conform to the National Electric Code and all applicable local

codes.

48.5 (1.9)

4.3 (0.169)

4.2

(0.165)

10.5 (0.41)

22 (0.86)

24˚

4.3 (0.169)

10.5

(0.41)

50˚

30

(1.18)

50.97

(2.0)

4.3

(0.169)

2

(0.07)

21.2

(0.83)

13.9

(0.54)

58

(2.28)

4.3

(0.169)

24˚

4.3 (0.169)

14.85 (0.58)

17

(0.66)

23.8

(0.93)

7 x M4

38.2 (1.5)

8.5

(0.33)

65 (2.55)

Application Notes

1. The sensor should be powered for approximately 5 minutes for

maximum precision.

2. The sensor indicator LED is green when the unit is powered.

3. The sensor indicator LED will be red if the lens becomes soiled

or contaminated.

4. The precision of the sensor is dependent on the combined

errors of linearity, resolution and temperature drift.

Accessories

Micron Conversions

Description

Cat. No.

2m (6.5ft) Micro

QD Cordset

889D-F4EC-2

Mounting Bracket

45BPD-BKT1

Protective

Mounting Bracket

45BPD-BKT2

1

μm

=

0.001 mm

1

μm

=

0.000039 inches

25.4

μm

=

0.001 inches (one thousandth)

20

μm

=

0.00079 inches (0.79 thousandths)