Thermal Transfer Systems TEMA Designations of Heat Exchangers User Manual

Page 5

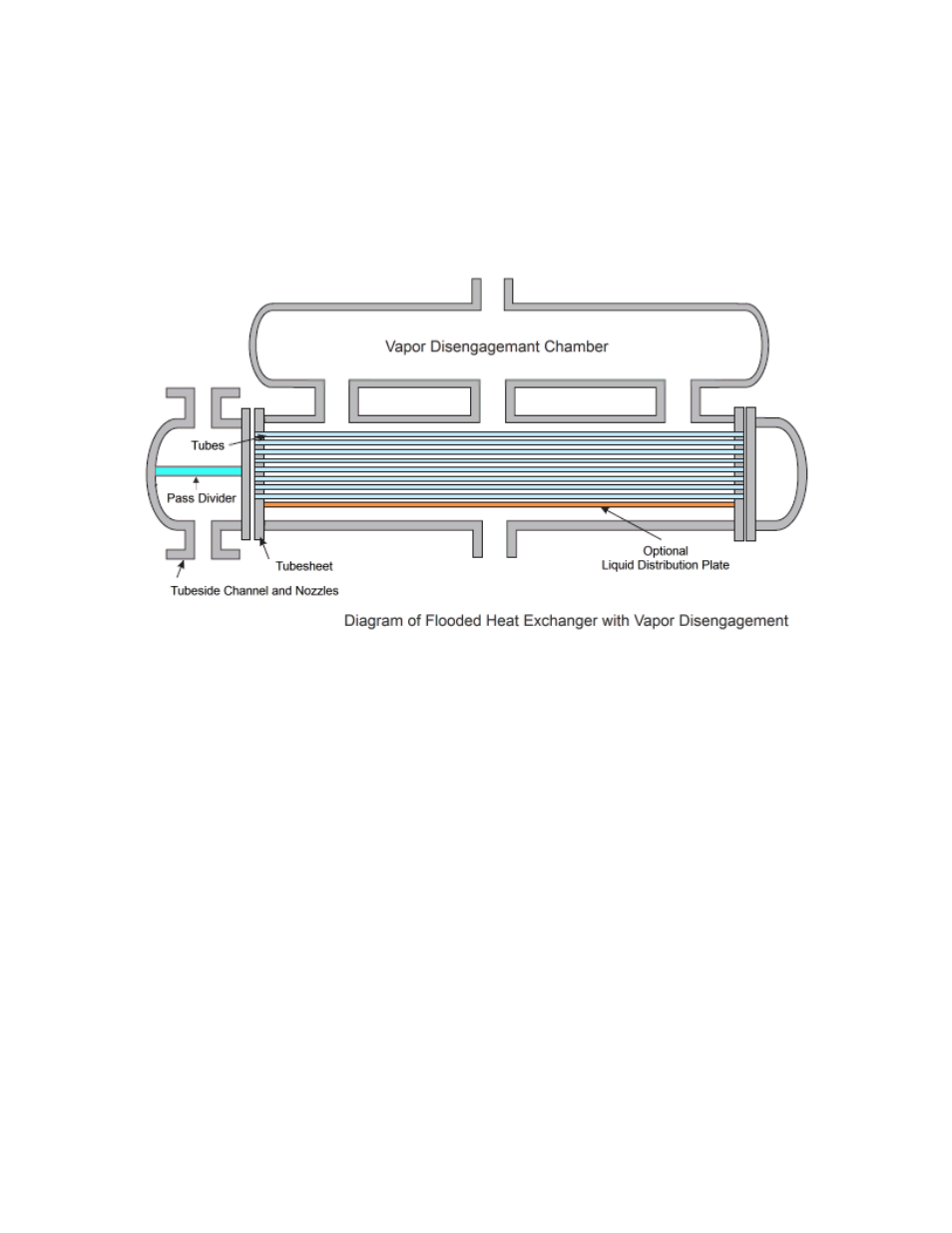

TEMA J Shells are typically specified for phase change duties where significantly reduced shell

side pressure drops are required. They are commonly used in stacked sets with the single

nozzles used as the inlet and outlet. A special type of J-shell is used for flooded evaporation

of shell side fluids. A separate vapor disengagement vessel without tubes is installed above

the main J shell with the vapor outlet at the top of this vessel.

The TEMA K shell, also termed a "Kettle Reboiler" is specified when the shell side stream will

undergo vaporization. The liquid level of a K shell design should just cover the tube bundle,

which fills the smaller diameter end of the shell. This liquid level is controlled by the liquid

flowing over a wier at the far end of the entrance nozzle. The expanded shell area serves to

facilitate vapor disengagement for boiling liquid in the bottom of the shell. To insure against

excessive liquid carry-though with the vapor stream, a separate vessel as described above is

specified. Liquid carry-through can also be minimized by installing a mesh demister at the

vapor exit nozzle. U-bundles are typically used with K shell designs. K shells are expensive for

high pressure vaporization due to shell diameter and the required wall thickness.