Thermal Transfer Systems TEMA Designations of Heat Exchangers User Manual

Page 2

NEN- Tubesheets are welded to both the Shell & Bonnets. Access to the tubes is through

covers on the channels. These units are favored in very high pressure designs as their

construction minimizes the tubesheet thickness and number of high pressure retaining flanges.

AEM/BEM/AEL-Shell side is completely welded up, however, the bonnets are removable.

Chemical, mechanical, and water blast cleaning of the tubes is possible, however you do not

have access to the shell.

You should avoid using Steam cleaning on a fixed tube sheet unit unless the unit has a shell

side expansion joint. The steam will cause the tubes to expand and pull out of the Tube Sheet

causing failure at startup.

DIFFERENTIAL THERMAL EXPANSION

Since the duty of heat exchangers includes the handling of fluids of differing temperature, flow

rate and thermal properties, differential expansion of the metals will take place.

When the terminal temperature difference between the fluids is substantial, over 50-60

degrees, these stresses can become severe, causing shells to become deformed and damage

mounting supports, tubes to deform the tube sheet or tubes to become broken or dislodged

from the tube sheet.

Fixed tube sheet designs are most vulnerable to differential thermal expansion, because there

is no inherent provision to absorb the stresses. One approach in common use is installing an

expansion joint in the shell pipe of such designs. This is a cost effective approach for pipe-size

shells. An expansion joint can also be installed in the tube side of floating head designs, but

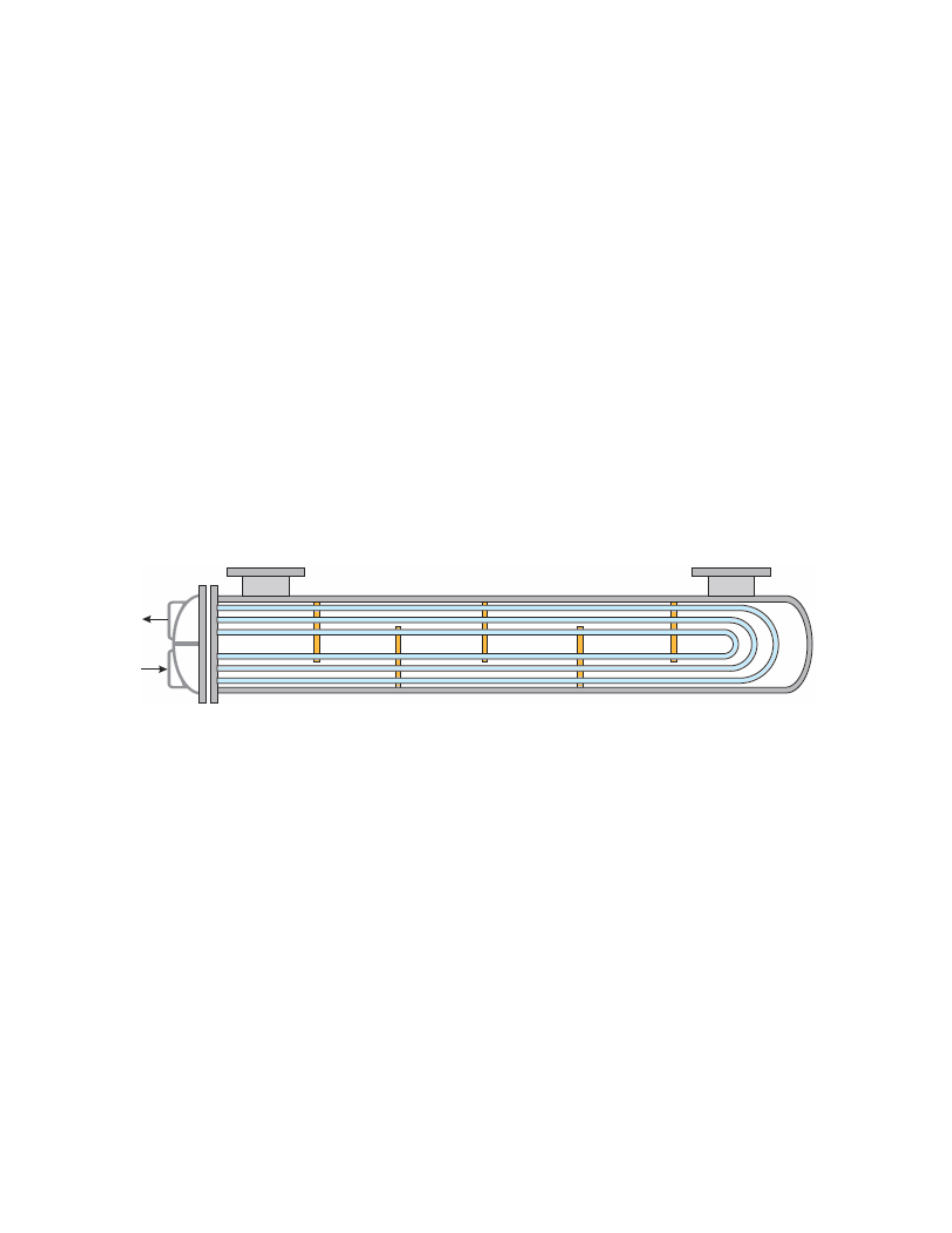

Diagram of U-Tube Heat Exchanger

manufacturing costs are much higher. Alternative approaches involve the design of a U-tube

bundle so that each tube can independently expand and contract as needed or by using a rear

floating internal tube sheet design which allows the entire bundle as a unit to expand and

contract. The floating head is typically sealed against the interior of the shell by means of

packing or O-ring designs.

U-tube designs while offering the best answer for differential thermal expansion have some

drawbacks. Individual tubes can be difficult of expensive to replace, especially for interior

tubes. Also, the tube interior cannot be effectively cleaned in the u-bends. Erosion damage is

also frequently seen in the u-bends in high tube side velocity applications. In large diameter

shells, the long length of unsupported tube in the u-bends of outer tubes can lead to vibration

induced damage.

FLOATING HEAD DESIGNS OF HEAD EXCHANGERS

In an effort to reduce thermal stresses and provide a means to remove the tube bundle for

cleaning, several floating rear head designs have been established.

The simplest is a "pull-through" design which allows the tube bundle to be pulled entirely

through the shell for service or replacement. In order to accommodate the rear head bolt

circle, tubes must be removed resulting in a less efficient use of shell size. In addition, the

SOURCE: WWW.WERMAC.ORG/