TapeTech CTPMP Bazooka Continuous Flow Pump Repair User Manual

Page 9

Pump Service

3A0912A

9

6.

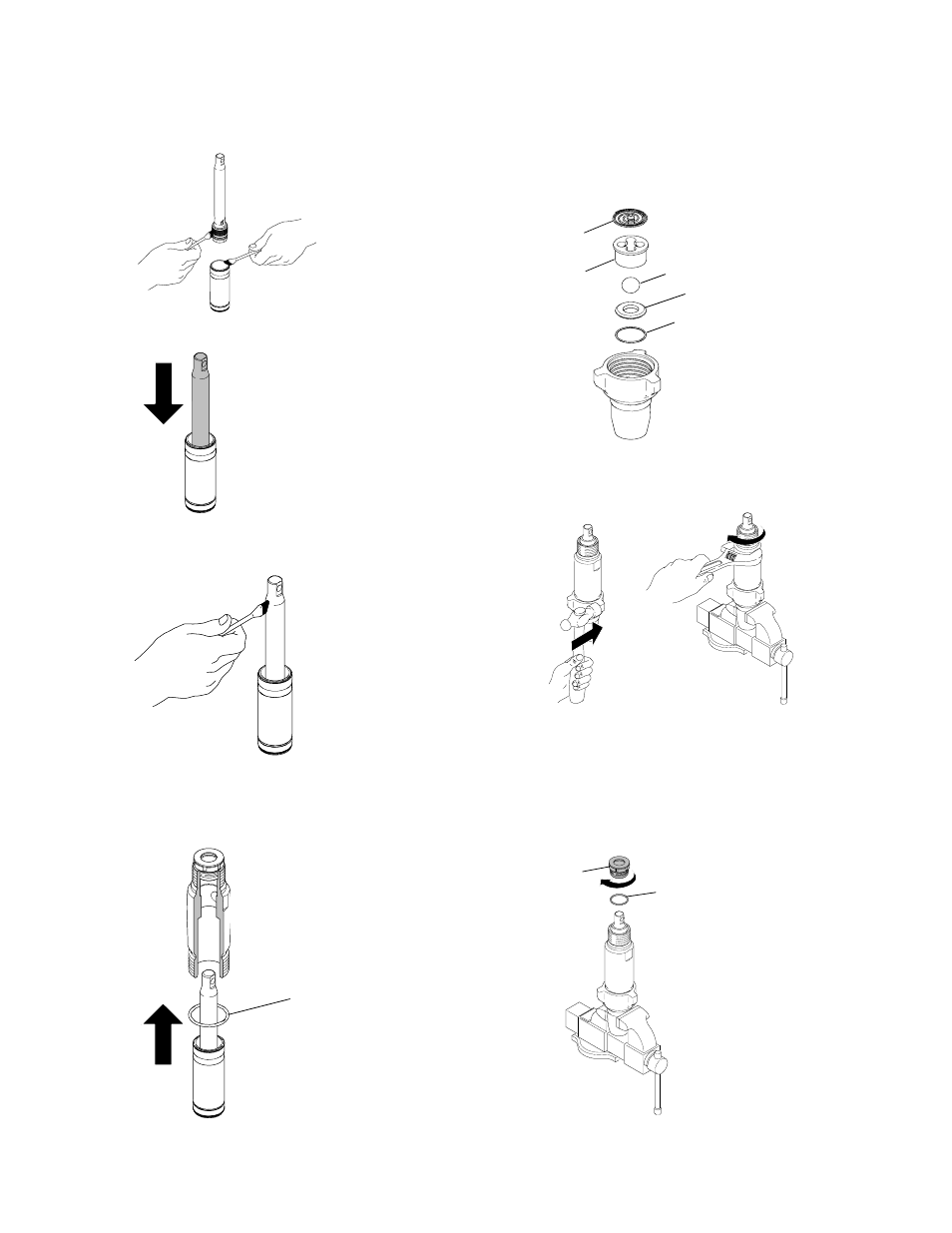

Grease piston packings and sleeve top edge.

7.

Carefully slide piston assembly into top of sleeve.

8.

Grease top inch or two of piston rod that will go

through the cylinder throat packings.

9.

Grease o-ring (315m) and place on sleeve. Slide

sleeve/piston rod assembly into bottom of cylinder.

Replace o-ring (315n) if desired. NOTE: O-ring

(315n) is not required for safe pump operation.

10. Reassemble intake valve with new o-ring (315a),

seat (309a) and ball (315b). Seat may be flipped

over and used on other side. Clean seat thoroughly.

Place intake spring (315r) on top of ball guide (317).

11. Install intake valve on cylinder. If a wrench is used,

torque to 200 +/- 15 ft-lb. If a wrench is not used, be

sure intake valve is tight against cylinder.

12. Torque seal and packing nut (312) down onto throat

adjustment spacer (302) to 140 +/- 10 in-lb. Remove

throat adjustment spacer (302) when pump pack-

ings begin to leak after too much use. Then tighten

packing nut down until leakage stops or lessens.

This allows approximately 100 gallons of additional

operation before a repacking is required.

315m

315b

309a

315a

317

317r

312

302