Pump service – TapeTech CTPMP Bazooka Continuous Flow Pump Repair User Manual

Page 7

Pump Service

3A0912A

7

Pump Service

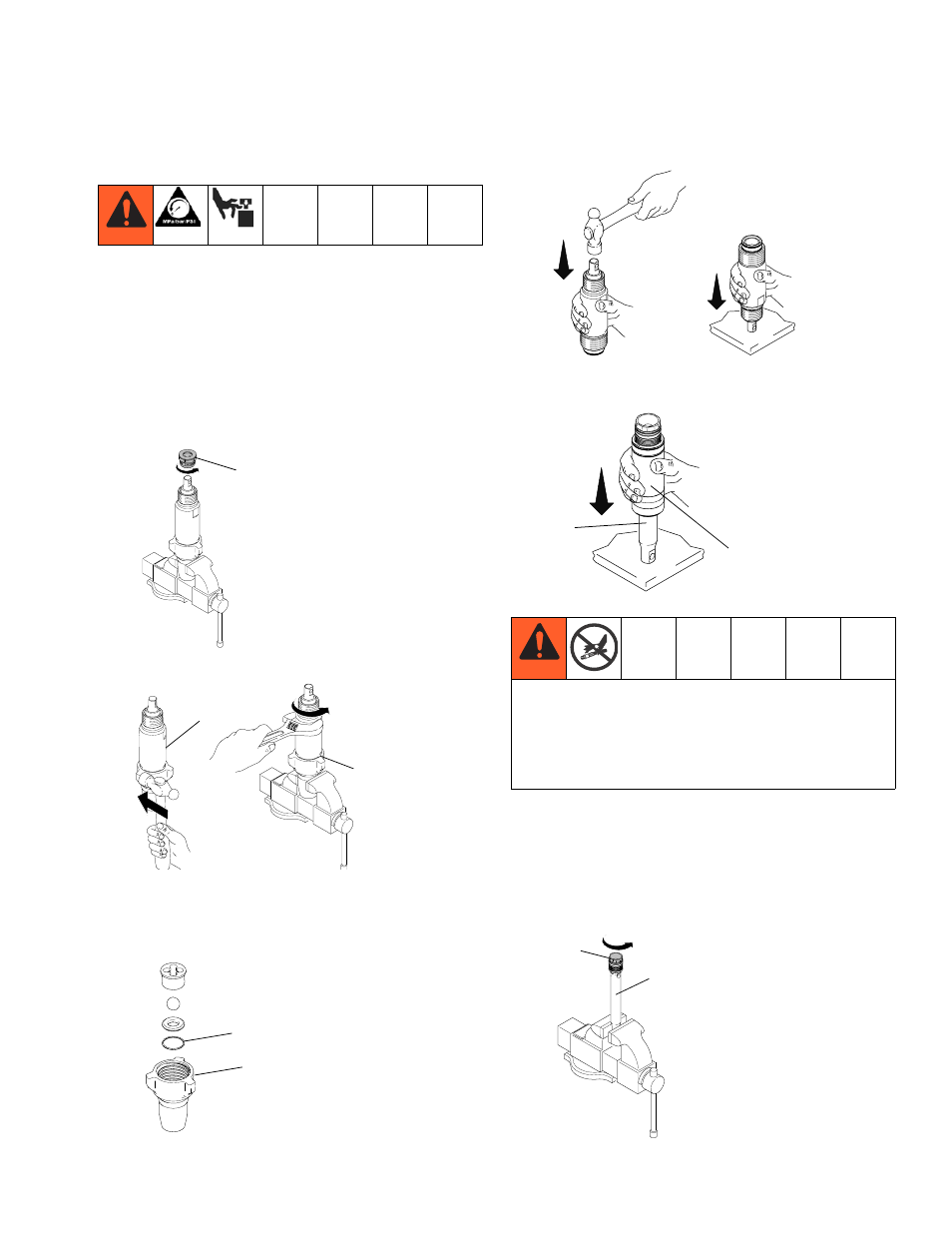

Disassemble the Pump

1.

Perform Pressure Relief Procedure, page 4.

2.

Perform Power Module Removal, page 4.

3.

Perform Pump Removal, page 5.

4.

Remove packing nut (312) and throat adjustment

spacer (302).

5.

Unscrew intake valve (319) from cylinder (304).

6.

Disassemble intake valve (319). Clean and inspect.

O-ring (315a) may require a pick for removal.

NOTE: if seat and ball need to be replaced, Carbide

Repair Kit 24F268 is available.

7.

Tap piston rod out of cylinder with a hammer or flip

over and tap piston rod out against a bench.

8.

Remove piston (311) from sleeve (306), or remove

sleeve from cylinder.

9.

Unscrew piston valve (313) from piston rod (311).

Clean and inspect parts. The piston has a special

thread locking/sealing patch. Do not remove the

patch. The patch allows four disassembly/assembly

procedures before it is necessary to apply sealant to

threads.

312

304

319

319

315a

COMPONENT RUPTURE HAZARD

Do not clean or wipe the piston valve threads. Cleaning

the piston valve threads could destroy the special sealing

patch and cause the piston valve to come loose during

operation, causing pump bursting and possible bodily

injury.

306

311

311

313