S&S Cycle Super E and G Series Shorty Performance Carburetors for 1936-84 Harley-Davidson Big Twins and 1957-85 Ironhead Sportster Models User Manual

Page 8

8

applicable.

G- Check fuel overflow hose routing. Avoid hot surfaces.

H- Test throttle to be sure it opens and closes freely. Turn

handlebars to extreme left and open and close throttle,

then turn bars to extreme right and check throttle. When

released, throttle should snap closed in all positions.

I- Reassemble components that were removed or

disassembled for carb installation. Consult authorized

Harley-Davidson® service manual for installation

procedure for stock parts not covered in S&S® carb

instructions.

J- Check fuel needle and seat assembly. Fill gas tank with

just enough fuel to test system. Lean motorcycle over

towards carburetor side, turn on fuel petcock, and wait

20 seconds. If gas runs out end of carb or out overflow

hose, turn off petcock and check needle and seat. See

"General Information."

K- Check fuel inlet fitting and fuel line connections for leaks.

Hose clamps must be tight.

NOTE: Fuel needle and seat assembly must completely shut off fuel

supply to carburetor bowl. Fuel inlet fittings and fuel line connections

must not leak.

Gasoline leaking past inlet needle may flood engine causing

contamination of oil supply and damage to engine.

Any gasoline leak represents a health and fire hazard.

L- Install air cleaner element. Insure that element goes

around outside edge of locating tang at 9 o'clock

position on backplate. Correctly installed element will

remain in place on backplate without support.

M- Apply blue tread locker to the three 3⁄4"-20 x 1"

mounting screws provided, and install air cleaner cover.

N- Fill gas tank.

INSTALLATION NOTES:

•

Due to the short installed length of the carb assembly, the

air cleaner cover may contact the gas tank of four-speed

shovelhead chassis with 5-gallon tanks. In such instances

an optional chromed, notched cover that will provide

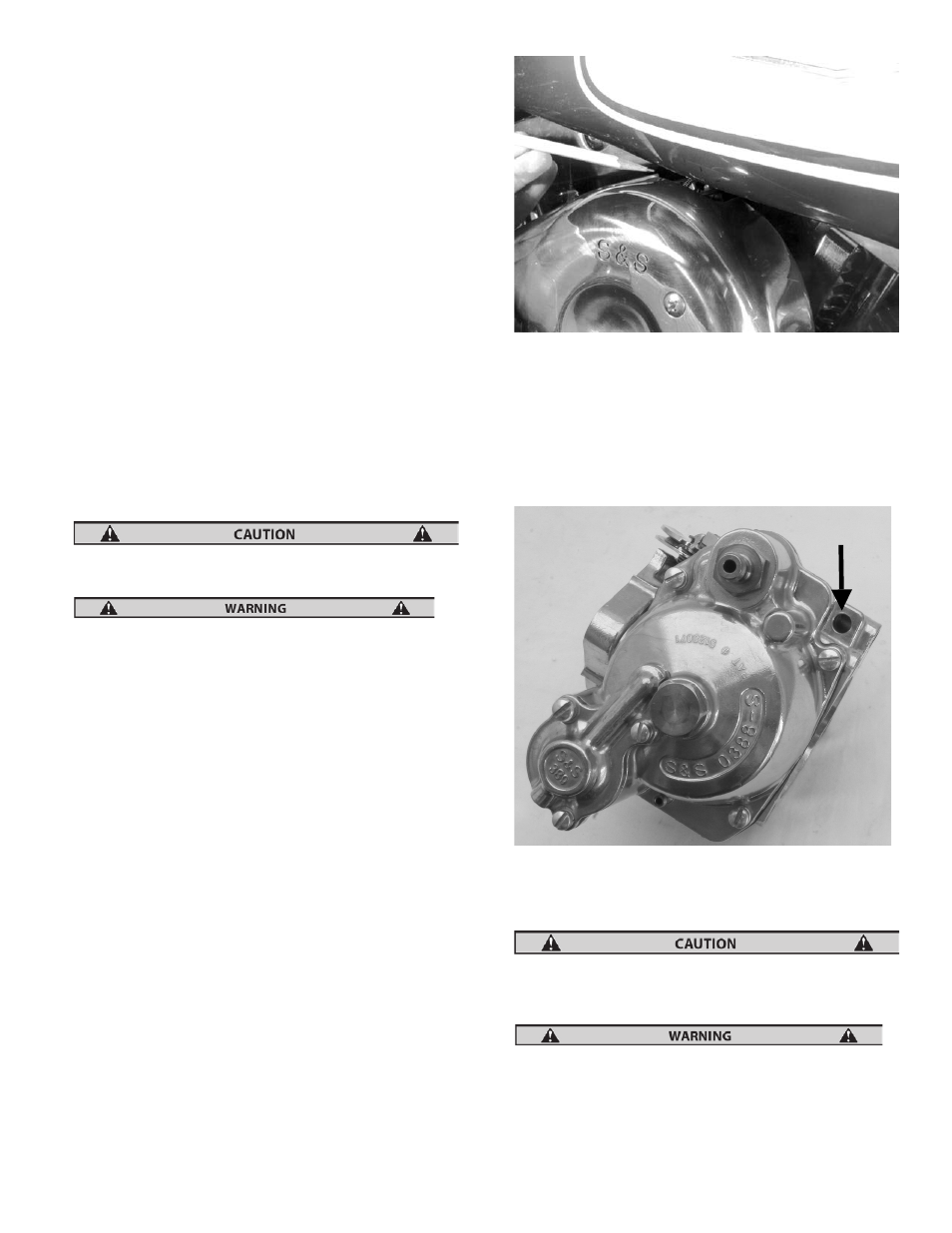

additional clearance can be ordered. See Picture 15.

Picture 15

•

An optional 1" spacer block can be installed between carb

and manifold as an alternative.

•

Bowl vent screw should be removed for any all-out racing

application, which includes use of air horn or air cleaner

without filter element. Exposed passage in carb body

maintains equal pressure between float bowl and

atmosphere. See Picture 16.

Picture 13

•

On any application where air horn is used instead of air

cleaner, S&S carb mounting bracket must be used to

securely fasten carb to engine. See line drawing on page XX

Improperly mounted carburetor may loosen from engine

resulting in gas or air leaks, poor performance and possible

damage to carburetor or other components.

Any gasoline leak represents a potential health and fire

hazard.

CARB OPERATION