S&S Cycle Super E and G Series Shorty Performance Carburetors for 1936-84 Harley-Davidson Big Twins and 1957-85 Ironhead Sportster Models User Manual

Page 13

13

or horsepower.

d- Continue procedure until mph/horsepower falls

off.

e- Decrease or lean main jet size by .002" to gain

best rpm and mph. When making runs on drag

strip, strive for consistent miles per hour, not

lowest ET.

2- Street Procedure - S&S uses "rpm" method to

determine main jet size. Under racing conditions this

level is where horsepower peaks and begins to taper

off and is where gear shifts occur. Main jet that

makes engine accelerate strongest or rpm through

gears quickest is correct.

NOTE: Placing engine under load by accelerating uphill may make

result of jet change more pronounced and easier to interpret.

a- Warm engine to operating temperature.

b- Accelerate rapidly through gears noting how

quickly and smoothly engine reaches rpm level

where pull of engine begins to fade and gear shift

occurs.

c- If engine backfires in carburetor and sputters or

"breaks up"and/or dies during acceleration,

increase or richen main jet size .004" larger and

road test again. Note engine smoothness and how

easily engine reaches rpm where gear shift occurs.

d- If engine runs flat and sluggish or "blubbers" or

will not take throttle, decrease or lean main jet

size .004" smaller and road test again. Note

engine smoothness and how easily engine

reaches rpm where gear shift occurs.

e- Continue changing main jets until jet which

makes engine accelerate or rpm through gears

quickest and smoothest is identified. S&S's®

experience is that jetting about .006" smaller

(leaner) than correct will make engine break up

and quit. Jetting about .006" larger (richer) will

make engine blubber and miss.

NOTES:

•

Correct carb jetting is essential for optimum performance

on street, strip and dynamometer. Other common causes

of poor performance in modified engine are inappropriate

exhaust and incorrect ignition timing.

•

S&S special main jet tool is extremely handy for changing

main jets. Try it, you'll like it!

E- Troubleshooting Tips for Intermediate and High Speeds

Engine will not run at steady speed or rpm or quits for no

apparent reason:

1- Restriction in fuel supply system - Gas tank vent

plugged, needle and seat not working properly (See

"General Information"), gas petcock too small, or

defective vacuum petcock. Stock petcock is generally

adequate, but may require running on reserve to

provide sufficient fuel for big inch engines. If fuel

delivery to carb is questionable, S&S recommends an

aftermarket high flow petcock.

2- Faulty ignition/electrical system - Fouled plugs, worn

points or condenser, defective coil or solid state

module, improper ignition timing, loose wire, faulty

circuit

breaker

or

ignition

switch.

Many

ignition/electrical problems occur repeatedly at same

rpm because of vibration specific to that rpm.

3- Incorrect intermediate and/or high speed jetting. See

"Adjusting Carb - Intermediate System" and "High

Speed Circuit or Main Jet."

4- Foreign material in air or gas passageway in carb

causing

flow

restriction.

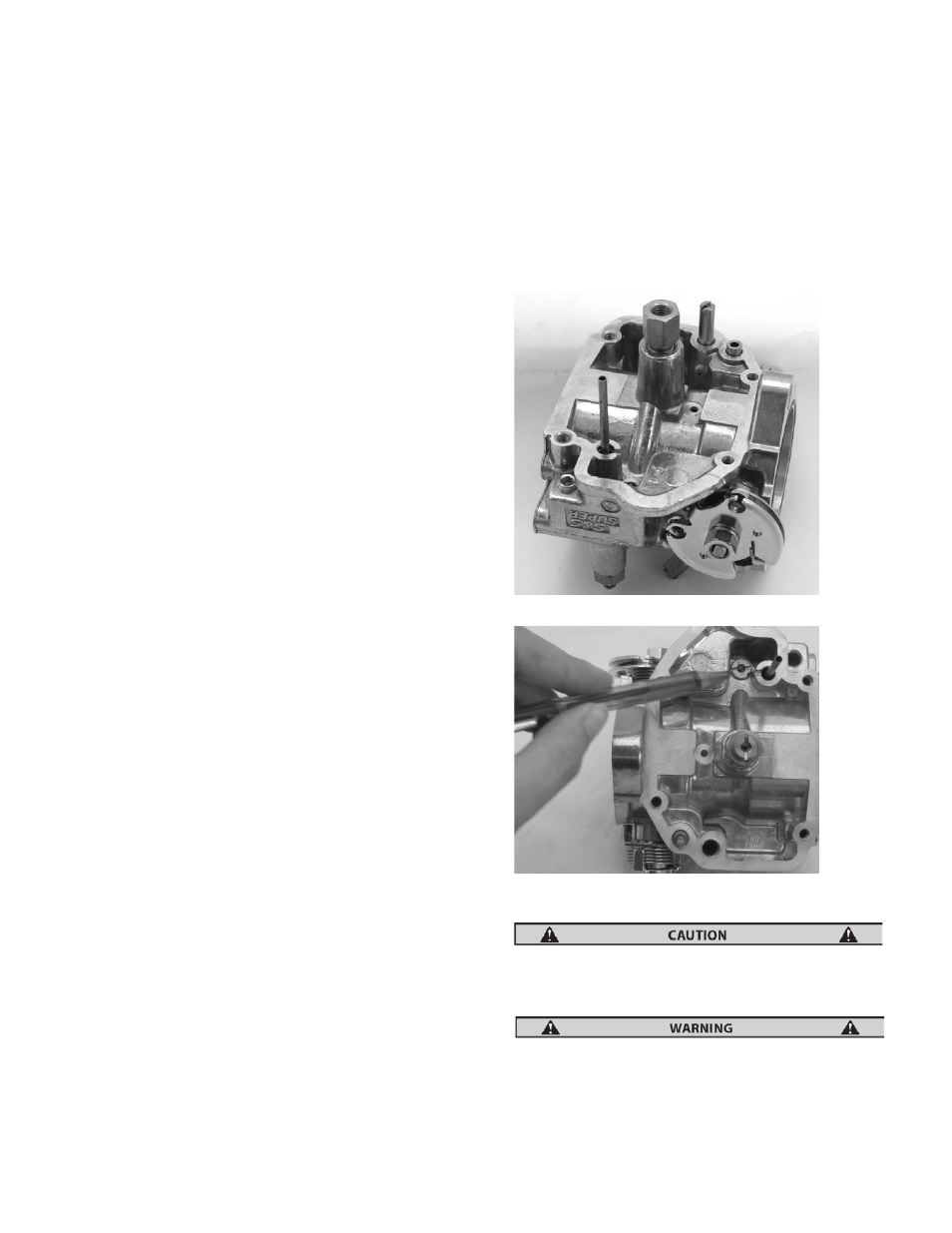

Picture

24shows

intermediate air bleed metering hole. Picture 25.

shows main discharge air bleed metering jet. Use

compressed air to clear holes

Picture 24

Picture 25

.

Do not use wire or drill to clear hole in carb bowl. If size of

hole is altered, starting system will be altered and carburetor

bowl irreversibly damaged.

Compressed air and particles dislodged by compressed air are

potentially harmful to eyes and body. Wear protective

goggles when using compressed air and always direct air

stream away from yourself and others nearby.