S&S Cycle Super E and G Series Shorty Performance Carburetors for 1936-84 Harley-Davidson Big Twins and 1957-85 Ironhead Sportster Models User Manual

Page 11

11

Picture 20

1- Start engine and run until slightly warm

(approximately 1 to 2 minutes).

2- Turn RPM adjustment screw to obtain idle of

approximately 1000 RPM.

3- Turn idle mixture screw clockwise, slowly leaning

mixture until engine starts to stumble. Next, turn

screw counterclockwise, slowly richening mixture,

until engine RPM rises and then falls off. Mixture

adjustment is correct when screw is positioned about

halfway between these points, or generally 1⁄4 to 1⁄2

turn out from lean side of adjustment range.

NOTE: Turning screw out (counterclockwise) makes idle mixture

richer. Turning screw in (clockwise) makes mixture leaner. Normally,

correctly adjusted screw will be between 11⁄4 and 3⁄4 turns out from

bottom if intermediate jet size is correct. Note that mixture screw

must be adjusted according to Step 3 above. Do not leave screw at

initial 11⁄2 turn setting without fine tuning.

4- After initial idle mixture adjustment, reset engine idle

to approximately 1000 RPM. Lower idle speed can

cause hard starting, poor throttle response, erratic

idle and unnecessary engine wear.

5- After engine has reached normal operating

temperature, repeat Steps 3 and 4.

IDLE CIRCUIT NOTES:

•

If idle adjustments are made before engine is fully warmed,

idle mixture will be rich when engine reaches operating

temperature. If ambient temperature is below 60 degrees,

engine may require 10-15 minutes of normal riding to

reach operating temperature.

•

Whenever intermediate jet change is made, idle mixture

screw must be readjusted.

•

If the idle mixture screw is more than 13⁄4 turns out after

idle mixture is correctly adjusted, it is a fairly good

indication that the intermediate jet may be too small and

should be changed to the next larger size. If the idle mixture

screw ends up less than 11⁄4 turn out, the intermediate jet

may need to be changed to the next smaller size. Be aware

that idle mixture screw adjustment can be effected by other

factors, but can quite often indicate rich or lean

intermediate jetting.

•

If idle mixture screw is turned completely in, engine should

not run at idle. If engine continues to run at idle with idle

mixture screw seated, recheck initial setting of idle speed

screw, and make sure enrichment plunger is seated. This

may also indicate damage to the idle mixture screw needle

and/or its seat.

B- Troubleshooting Tips - engine will not idle:

1- Improper idle mixture or rpm setting.

2- Intake manifold air leak.

3- Incorrect ignition timing, malfunctioning automatic

advance mechanism, or other ignition problem.

4- Foreign material in air or gas passageway in carb

causing gas flow restriction to idle or intermediate

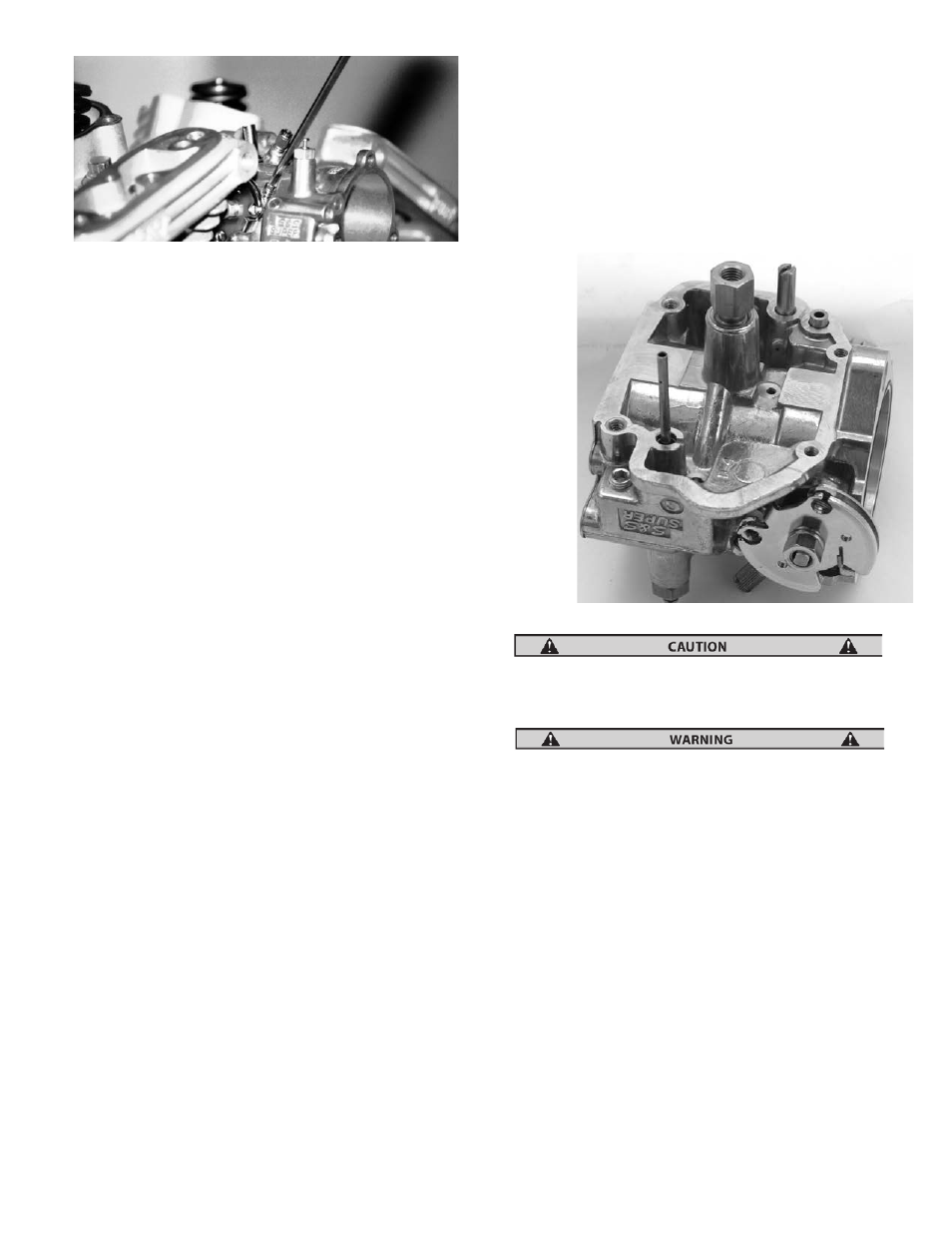

circuit. Picture 21 shows intermediate air bleed

metering hole. Clear holes with compressed air.

Picture 21

Do not use wire or drill to clear hole. If size of hole is altered,

starting system will be altered and carburetor bowl

irreversibly damaged.

Compressed air and particles dislodged by compressed air are

potentially harmful to eyes and body. Wear protective

goggles when using compressed air and always direct air

stream away from yourself and others nearby.

5- Enrichment/fast idle plunger not seated causing

excessively rich mixture. Be sure enrichment lever is

fully disengaged (in down position) allowing plunger

to bottom and seal passageway. Remove air cleaner

backplate. Lift and release plunger several times,

letting it "snap" closed to fully seat against carb body.

When backplate is reinstalled on carb, be sure lever is

engaged in plunger properly and that plunger is not

lifted as mounting screws are tightened. See Picture

17 on Page x.

6- 1⁄4" insulator block between carb and manifold

omitted. Heat transfer from manifold to carb may

cause temporary rich condition at idle and low rpm

when engine restarted after being shut off for a short

time. Install insulator block to minimize heat transfer.

C- Adjusting Intermediate System - (See Jetting Chart Page

XX) Intermediate rpm range is used most often under