S&S Cycle Super E and G Series Shorty Performance Carburetors for 1936-84 Harley-Davidson Big Twins and 1957-85 Ironhead Sportster Models User Manual

Page 14

14

6-

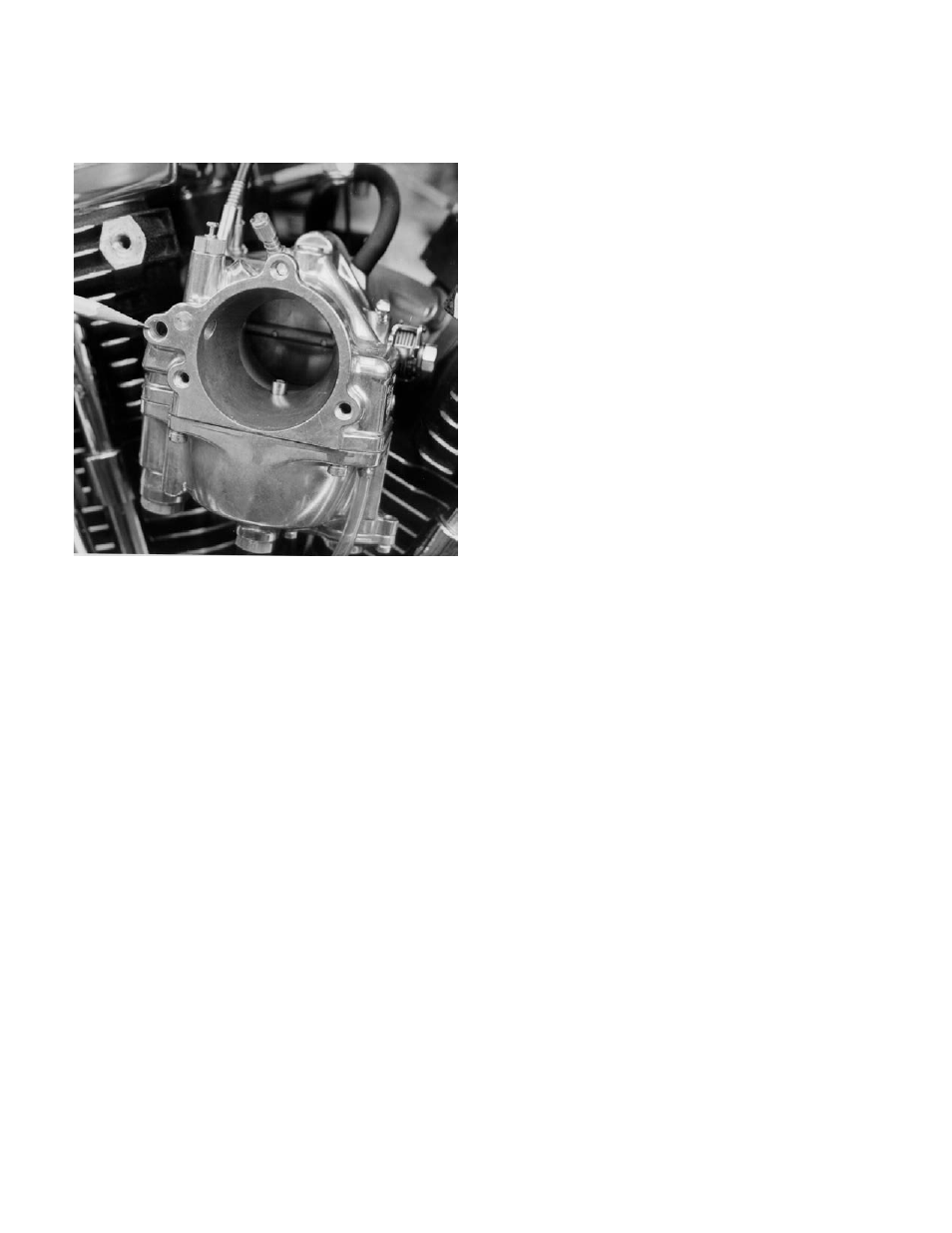

No air cleaner used or air cleaner used is brand other

than S&S. Some air cleaners restrict air flow so that carb cannot

draw air as freely as needed. Also, some air cleaners may

obstruct bowl vent hole on inlet end of carb and change bowl air

pressure. See Picture 27.

Picture 27

NOTE: Bowl vent hole passage leads to cavity above fuel in bowl.

Passage equalizes bowl pressure and atmospheric pressure. If high or

low bowl pressure relative to atmospheric pressure develops, engine

may run erratically.

7- Insulator block between carb and manifold not used.

Heat transfer from manifold to carb may cause

temporary rich condition at idle and low rpm when

hot engine is restarted after being shut off for a short

time. Install insulator block to reduce heat transfer.

8- Air cleaner without element or air horn used without

removing bowl vent screw located in downward

facing boss on throttle cable side of carburetor body.

See Picture 15 on Page XX.

9- Poor engine condition - Leaking or sticky valves,

weak or broken springs, pushrod flex, improper

clearances for high lift cam, or defective camshaft

with improper valve timing.

10- Inappropriate exhaust system.

NOTE: S&S® has found that long, large diameter exhaust pipes, either

baffled or unbaffled, may present insurmountable tuning problems

when combined with S&S carburetor. If engine equipped with such

pipes does not respond to normal tuning procedure, contact exhaust

manufacturer for his tuning suggestions or call S&S for exhaust

recommendation.

11- Too much gear- Horsepower insufficient to pull

gearing.

12- Incorrect float setting - Setting float too high will

cause engine to run rich at idle and at low speeds,

and may prevent jet change from correcting over rich

mixture. Float setting too low will cause poor off idle

response and may cause mixture to "lean out" at high

speed or when motorcycle leaned over in curve due to

insufficient fuel reserve in bowl. See General

Information on Page XX for float jetting instructions

and specifications.

13- Fuel standoff - Occasionally, fuel may be seen misting

out carburetor at full throttle when air cleaner is

removed. Because carburetor is simply a conduit

through which air and fuel enter engine, it does not

cause fuel standoff. Usual cause is cam timing and

exhaust reversion.

14- Overflow hose missing from the carb bowl can cause

engine to miss and break up at high speeds. This

problem will more than likely not occur on the dyno

because the motorcycle is not moving through the

air.

Adjustable Air Bleed for Super E and G Carburetors

The main air bleed passage in S&S Super "E" and "G"

carburetors is fitted with a replaceable .040" jet. See Picture

26 on Page XX. The replaceable jet allows changing the size of

the main air bleed. Carburetors with this feature can be

identified by a serial number that begins with the letter E or

higher.

NOTES:

•

The standard .040" diameter air bleed is the optimum size

for most engine combinations, and should not be changed

under most circumstances, regardless of intermediate and

main jet selections.

•

Changing the main air bleed size should be done only after

determining a mid range driveability problem cannot be

corrected by changing the intermediate and main jets.

•

For tuning the main air bleed, S&S® recommends an initial

increase from the standard .040" jet to a .048" jet as a

starting point. Available jets and part numbers are listed in

the S&S

catalog.

•

It is never necessary to reduce the size of the main air bleed

below .040".

•

Shifting the start of main jet operation to a point higher up

the rpm scale can lessen the effects of mid rpm driveability

problems caused by mismatched cam and exhaust

systems, but will not allow the engine to perform as well as

it would with a well designed exhaust system.

INTERMEDIATE AND HIGH SPEED NOTES:

•

Carburetor jetting and spark plug color - While spark plug

color may be used to help determine carburetor jetting,

S&S recommends that our instructions be used as primary

jetting guide and that plug color indications be used as

secondary aid. Different brands of gasoline, gasoline

additives, engine heat, type of plugs, and spark plug heat

range can effect plug color making plug reading difficult

for average tuner. Also, new plugs usually require road test

of 10 miles or more to properly develop color. This means

that quarter mile tests may not be long enough to be a

good indication of carb jetting. It is best to use

recommended spark plug type and to consult spark plug

manufacturer with questions.