S&S Cycle Super E and G Series Shorty Performance Carburetors for 1936-84 Harley-Davidson Big Twins and 1957-85 Ironhead Sportster Models User Manual

Page 4

4

remaining hole on left in Picture 5.

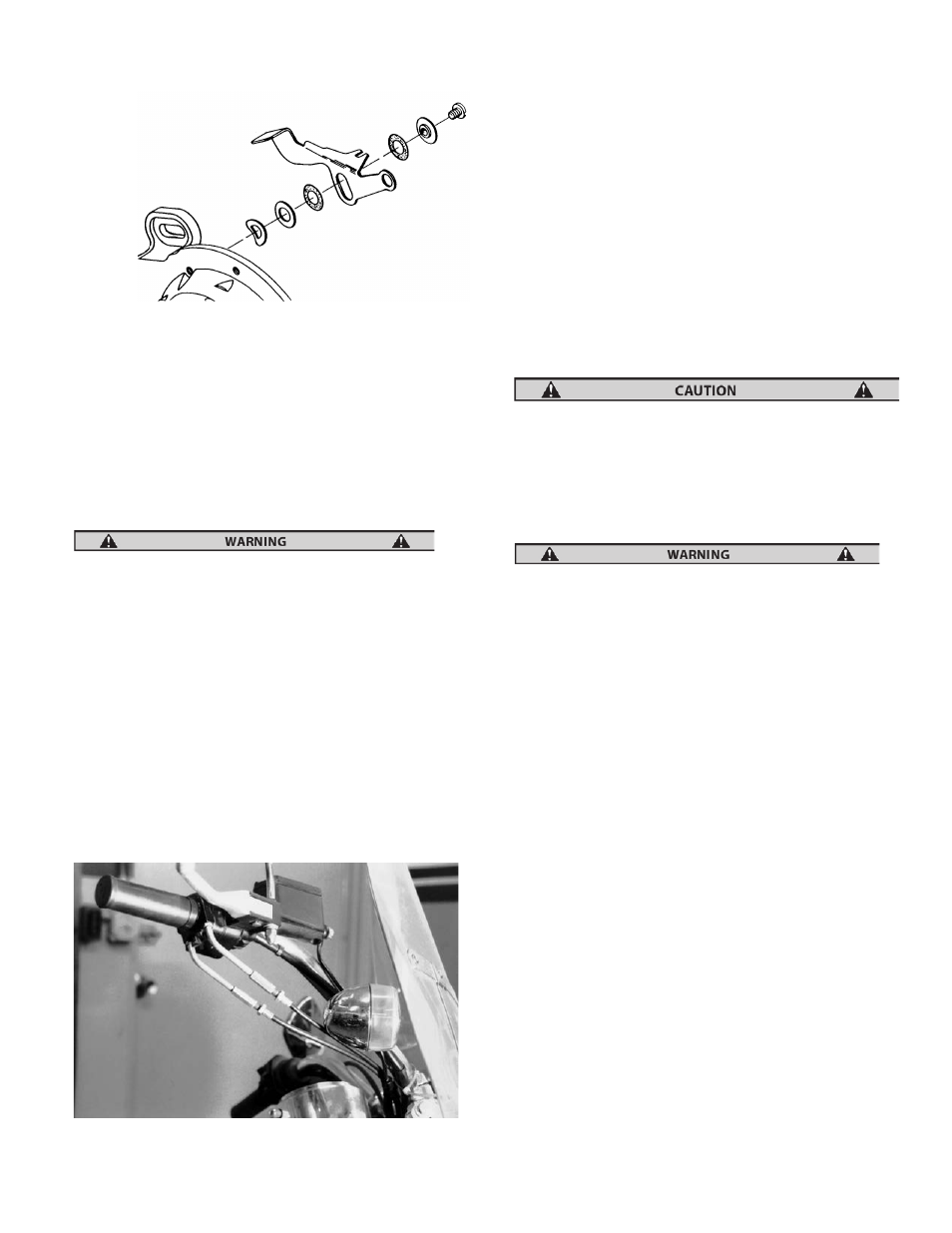

5- Assemble fast idle mechanism as shown in Figure A.

Figure A

On current backplates, the pivot point for the enrichener does

not have a screw holding it; a boss has been cast onto the

backplate to replace this.

3- Throttle Preparation

NOTE: Throttle grip assembly must be assembled correctly and work

freely to prevent possible sticking during operation. Throttle must

snap closed when released. Cable routing must be free of tight bends

to minimize friction between cable and housing.

If throttle does not work freely, it may inadvertently stick

open possibly causing loss of control of motorcycle and

personal injury to operator or others.

A- Install new throttle assembly - Motorcycles not equipped

with two cable pull open-pull closed type throttle

assembly.

1- Remove existing throttle cables and throttle grip

assembly. Note routing of stock cables.

2- Install new throttle assembly and throttle cables.

Position grip and cables so cables can be angled back

toward carb for easy adjustment and free operation.

3- Apply light coat of cable lubricant to cables/fittings.

4- Loosen cable free play adjustment locknuts and

thread adjusting screw so half of threads are

exposed. See Picture 6.

Picture 6

B- Prepare existing throttle assembly - 1981-1985 Harley-

Davidson® Sportster® and 1981-1984 big twin chassis

equipped with two cable pull open-pull closed type

throttle assembly.

1- Loosen cable free play adjustment locknuts and

thread adjusting screw so half of threads are

exposed. See Picture 6.

2- Clean grease and dirt off cables, cable housings and

cable fittings.

3- Apply light coat of cable lubricant to cables and

fittings.

4- Install New Manifold and Mounting Hardware

NOTE: When applicable, all carburetor mounting brackets and

hardware supplied in kit must be installed to secure carburetor and

air cleaner backplate assembly or air horn rigidly to engine.

Improperly mounted carburetor could loosen unexpectedly,

resulting in air leak, poor performance and possible damage

to engine or carburetor.

Incorrect combinations of mounting hardware may cause

mounting bolts to bottom out in holes or inadvertently

contact other parts possibly causing damage to engine or

carburetor components.

Improperly mounted carburetor may break free in event of

collision or other vehicle accident creating a fire hazard with

potential personal injury to operator/others.

A- All models: Clean intake ports on cylinder heads to insure

proper manifold to head seal.

NOTE: Cylinder heads for knucklehead engines 1936-'47 and

panhead engines 1948-'54 must be converted to o-ring style

manifold and seals. Conversion kits are available from S&S®. See the

Vintage section of the S&S Catalog.

B- All models: Install S&S® intake manifold. If applicable,

vacuum advance fitting must point upward. Do not

completely tighten manifold clamps.

C- Knucklehead and panhead engines - Remove center

crankcase stud nut between tappet blocks. Install

bracket, to connect crankcase stud to bottom carb-

manifold mounting bolt and reinstall nut. Do not tighten

at this time.

D- Shovelhead engines 1966 to 1982 - Bolt end of bracket

with sharp bend to front rocker cover using 5⁄16"-18 x

5⁄8" bolt, 5⁄16" flatwasher and 5⁄16" lockwasher provided

in kit. Do not tighten at this time.

E- Shovelhead engines 1983 to 1984 - Remove center

crankcase stud nut between tappet blocks. Install

adjustable bracket to connect crankcase stud to lower

carb-manifold mounting bolt and reinstall nut.

F- Sportster® models 1957 to 1985 - Bolt end of bracket with

sharp bend to front tappet guide using 5⁄16"-18 x 11⁄4 "

bolt, 5⁄16" flatwasher and 5⁄16" lockwasher provided in

kit. Do not tighten at this time.