S&S Cycle VFI Induction System User Manual

Page 5

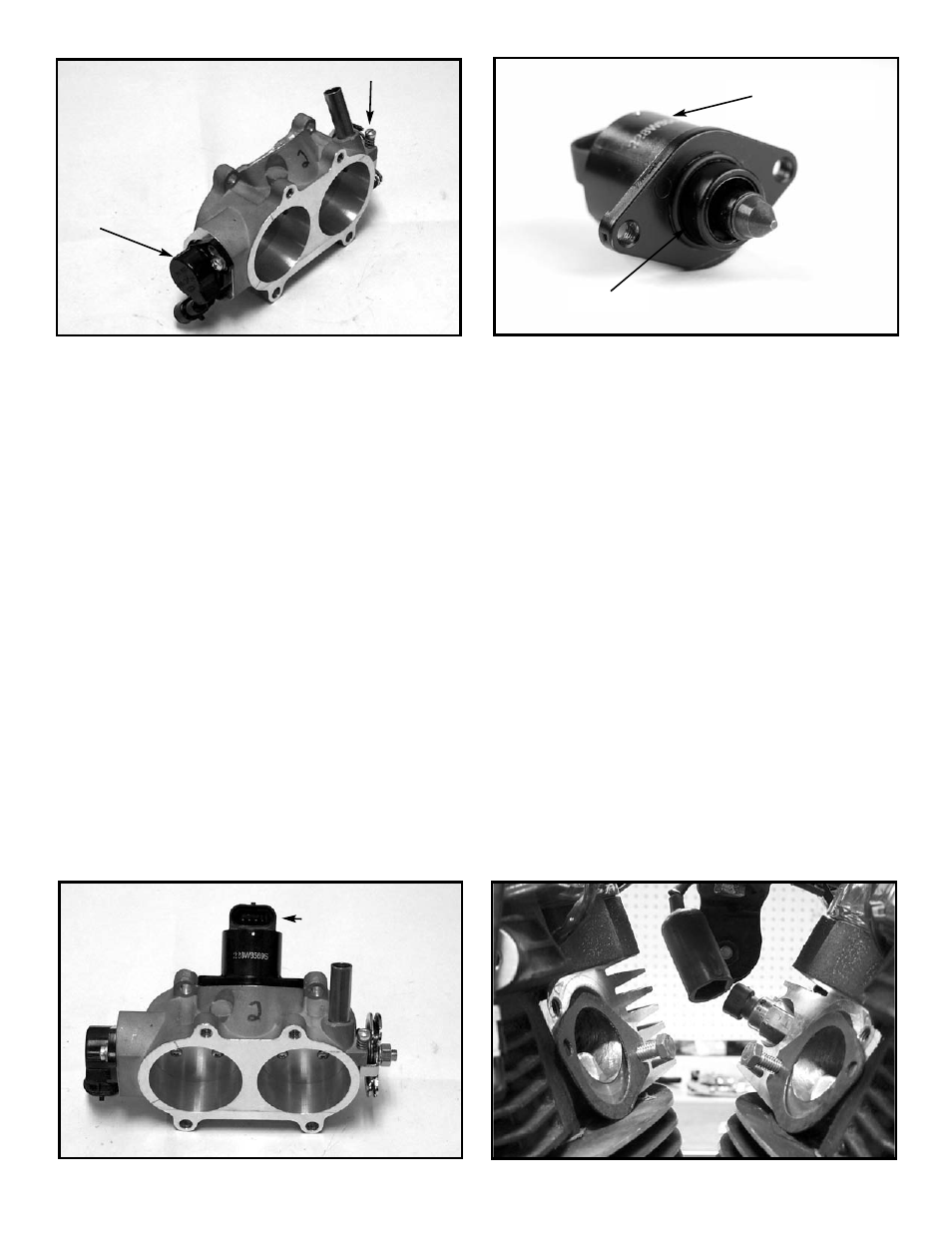

NOTE: Do not change position of the TPS or the throttle stop

screw at assembly. They have been changed at S&S

®

. Any

re-positioning will throw off calibration.

See Picture 8.

1.

Install Idle Air Control (IAC) Motor

a.

Slide a new O-ring (included with the kit), over the

end of IAC motor (also included in the kit), and be

sure Vaseline or clean engine oil is applied to the

O-ring prior to assembly.

See Picture 9.

b.

Install the IAC motor onto the S&S VFI throttle

body. Do not tear the O-ring during assembly,

and be sure Vaseline or clean engine oil is

applied to the O-ring prior to assembly. Orient

the electrical connector so it points away from

the engine and throttle body.

See Picture 10.

c.

Coat the threads of the hex head M5x.8

screws included in kit with Loctite

®

222

(Purple). Use Loctite

®

242 if 222 is not

available. Fasten IAC motor to throttle body

and tighten screws to 20-24 in-lbs.

D. Install Fuel Rail, Manifolds and Throttle Body

1. Attach Fuel Rail/Manifolds Assembly to Engine

a.

Partially thread the two provided

5

/

16

" -18 hex

head screws into the tapped holes where the

open-ended slots on the manifolds flanges will go.

NOTE: Verify that the provided

5

⁄

16

"

-18 x 1.00 screws will not

bottom out in the heads when attaching the manifolds. If the

screws provided are too long, use the original screws from

the old induction module assembly.

b.

Apply a thin coating of silicone sealer on both

sides of manifold flange gaskets. Place a

manifold flange gasket on each port surface, with

the flat edge up. (The same gasket part number

is used for both front and rear ports). The

mounting holes/intake port alignment should be

verified before continuing.

See Picture 11.

5

Picture 8

Throttle Position

Sensor (TPS)

Picture 9

Idle Air Control Motor

(IAC)

O-ring

Picture 10

Throttle position screw

Picture 11

Connector pins face

away from engine.