Maintenance mode – RKI Instruments SD-705EC User Manual

Page 20

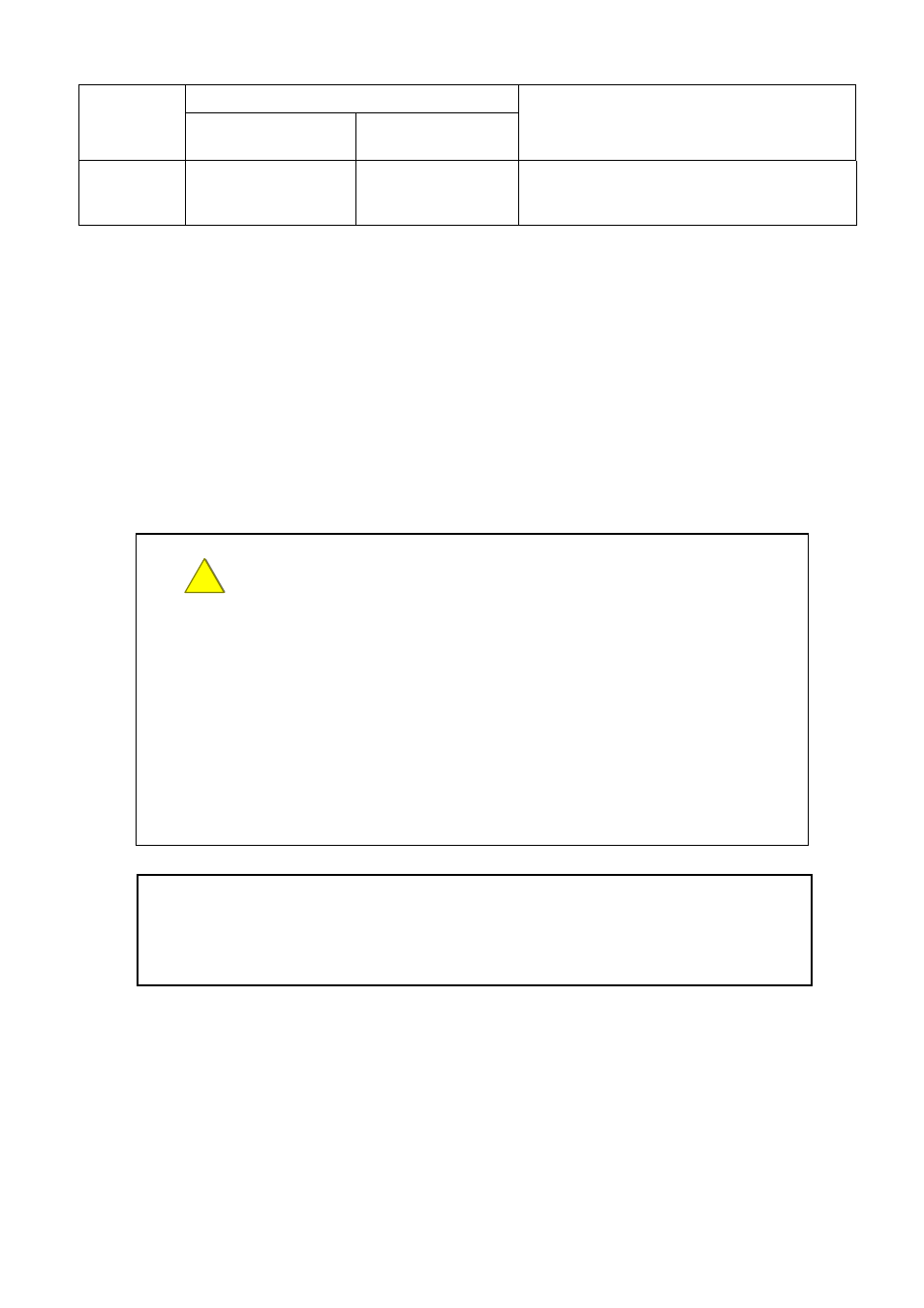

PT2E-1140

Contents of inspection

Inspection

point/item

Inspection by every 6

months

Yearly inspection

Judgment

Sensor

sensitivity

Calibration with gas

Sensor replacement

and calibration with

gas

Adjust zero and span according to Gas

Sensitivity Calibration Method

6 months inspection and yearly inspection include daily and monthly inspection respectively.

Following items are performed in periodical inspection.

①Daily check

②Cleaning of device ③Calibration

④Function check ⑤Parts replacement ⑥etc.

☆To keep the safety performance of the instrument, recommend to make maintenance

contract concerning to regular inspection, adjustments, repairing, etc. including gas

calibration.

!

・This is a safety instrument and the inspection every 6 months or more is

mandatory to ensure the safety. If the unit is used by continuously without

inspection, the sensor sensitivity may change, resulting in failure of correct

detection.

・Before zero adjustment, confirm with a portable gas detector that there is no

gas in the neighborhood. If zero adjustment is made in an atmosphere

containing gas, no correct calibration is expected. If gas leakage actually

occurs, the unit shows the low concentration value, possibly leading to a

hazardous state.

WARNING

Be sure to inform sections concerned beforehand when performing

adjustment of the gas sensitivity

REMARKS

*

4−2 Maintenance Mode

Adjustment is performed by control key in maintenance mode without opening the lid.

Following is a menu of maintenance mode and common operation method.

In maintenance mode, 4-20mA output becomes 2.5mA and SKIP light is flickering.

All operation performed by control key.

19