Retsch SR 200 User Manual

Page 16

2/8/2012

Retsch GmbH

16

0002

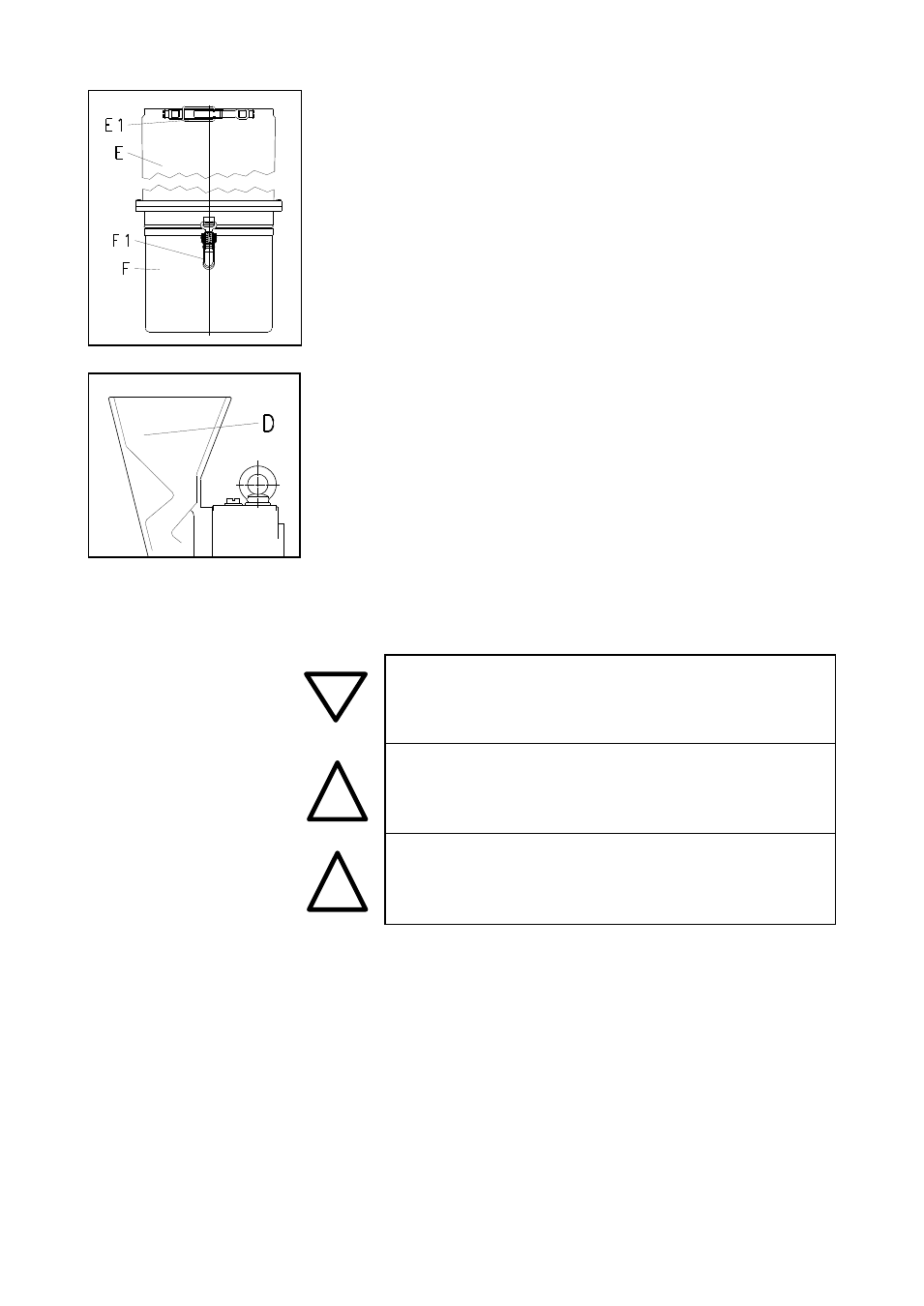

Filter hose and collecting pan

Fig.10

Fig.11

With the use of a cloth filter hose or a Conidur filter, available as

an accessory, between the SR 200 and the collecting pan, the air

stream caused by the rotating rotor is taken off and conveyed

downward to the material discharge. Furthermore, it accelerates

the material throughput and ensures a gentle crushing process.

Fig.10

* Push filter hose E over the flange while holding the clamping

clip at an angle.

* Clamp the lock E1

* Hang in the collecting pan F

* Clamp the locks F1

If the collecting pan is mounted without a filter hose, it can be

expected that dust will escape from the feed funnel D, and so you

should never operate the SR 200 without a filter hose or Conidur

filter.

Feed material to be crushed

The maximum feed grain size should not exceed 15mm.

For batch or continuous operation, the SR 200 can be retrofitted

with a 30l plastic collecting receptacle and a feed device of the

type DR 100/75, which are available as accessories.

* Close the SR 200 and switch on

* Slowly feed the material to be crushed into the feed funnel D

Fig.11

The rebound safeguard installed in the feed funnel D prevents the

feed material from bouncing back.

Fig.11

Only feed the material to be crushed into the feed funnel slowly and

continuously with the SR 200 running.

The material to be crushed or excessive feed quantity can bring the

SR 200 to a standstill and this may damage mechanical

components.

!

During crushing, material in dust form may escape from the feed funnel.

In the case of toxic or otherwise health-hazardous materials, use an

extraction device.

Danger from inhalation of health-hazardous dust.

!

Many materials form explosive air mixtures. Check the properties of the

material you are crushing.

Explosion hazard!