Minimum. 0.3mm, Cleaning and service – Retsch SM 200 User Manual

Page 35

Cleaning and service

35

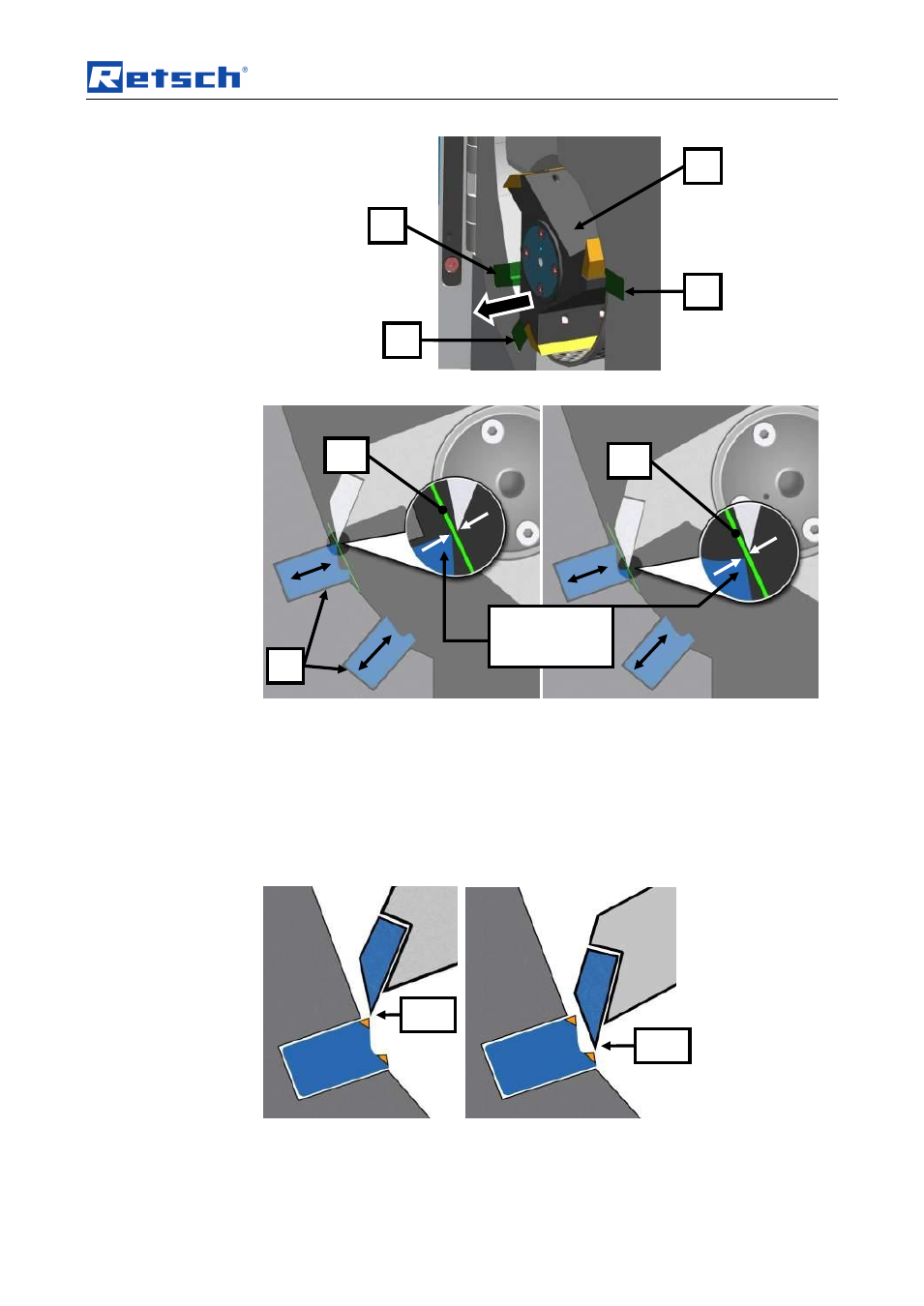

Fig. 27: Twist the rotor until it rotates freely

Fig. 28: Setting the cutting gaps

•

Use a (BL) feeler gauge to check the cutting gap between all three (SL)

cutting bars. The gap should be at least 0.3 mm.

The (BL) feeler gauge must be put on the two cutting surfaces as shown in the

illustration. The cutting gap must have the same spacing along its entire depth.

Check the cutting gap along its entire depth therefore.

The cutting edge with the smallest spacing from the knife marks the cutting gap

(SP1/2). The second cutting edge can have a larger cutting gap.

Fig. 29: Cutting gap

Minimum.

0.3mm

H

BL

H

BL

H

SL

H

SL

H

SL

H

H

H

SL

H

SP1

H

SP2

H

See also other documents in the category Retsch Equipment:

- BB 50 (41 pages)

- BB 100 (24 pages)

- BB 200 (24 pages)

- BB 300 (24 pages)

- Cryomill (68 pages)

- CryoMill Autofill 50l (28 pages)

- DM 200 (20 pages)

- DM 400 (60 pages)

- Emax (67 pages)

- GM 200 (44 pages)

- GM 300 (44 pages)

- MM 200 (32 pages)

- MM 400 (32 pages)

- PM 100 (44 pages)

- PM 400 (36 pages)

- PM GrindControl (48 pages)

- RM 200 (36 pages)

- RS 200 (32 pages)

- SK 100 (24 pages)

- SM 100 (48 pages)

- SM 300 (44 pages)

- Cyclone - SM 300 (20 pages)

- SR 200 (24 pages)

- SR 300 (24 pages)

- TWISTER (44 pages)

- ZM 200 (32 pages)

- AS 200 jet - Automatic Vacuum Regulation (6 pages)

- AS 200 control - natural frequency (32 pages)

- AS 200 (36 pages)

- AS 200 jet (56 pages)

- AS 200 jet (48 pages)

- AS 200 tap 30.025.0001 (28 pages)

- AS 200 tap 30.025.1001 (28 pages)

- AS 300 (32 pages)

- AS 400 (32 pages)

- AS 400 (28 pages)

- AS 450 basic (40 pages)

- AS 450 basic (44 pages)

- AS 450 control (52 pages)

- DR 100 (40 pages)

- DR 100 (28 pages)

- PP 25 (32 pages)

- PP 40 (28 pages)

- PT 100 (36 pages)