Maintenance/service – MacDon 802 Bi-Directional Adapter User Manual

Page 37

36

MAINTENANCE/SERVICE

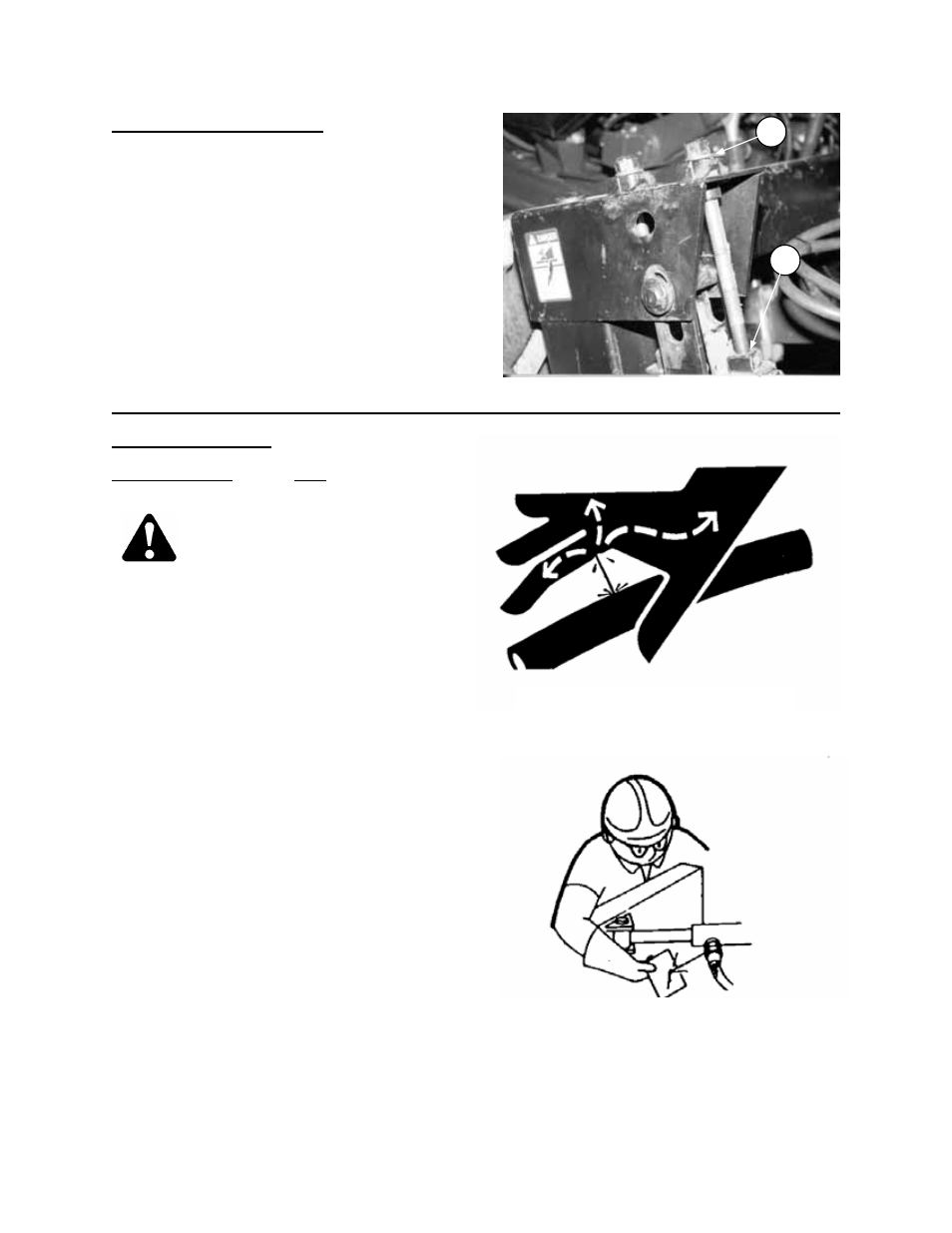

FLOAT SPRING HARDWARE

To prevent premature wear, apply an anti-seize/

lubricating compound to header float spring

adjustment bolt threads (A) and washers (B) (four

of each) before adjusting header floatation.

HYDRAULIC SYSTEM

Hydraulic Hoses - Check daily for leakage.

WARNING: Avoid high-pressure

fluids. Escaping fluid can

penetrate the skin causing serious

injury. Relieve pressure before

disconnecting hydraulic lines.

Tighten all connections before applying

pressure. Keep hands and body away from pin-

holes and nozzles which eject fluids under

high pressure. Use a piece of cardboard or

paper to search for leaks. IF ANY fluid is

injected into the skin, it must be surgically

removed within a few hours by a doctor

familiar with this type of injury or gangrene

may result.

IMPORTANT:

• Ensure all hydraulic couplings are properly

mated and fully engaged before operating

header.

• To avoid wasting oil, do not direct more flow to

the header drive hydraulic circuit than can be

handled by the adapter flow control (maximum

18 GPM). See "Header Controls" in Operation

section.

• Keep hydraulic coupler tips and connectors

clean. Dust, dirt, water and foreign material

are the major causes of hydraulic system

damage.

• To prevent improper mixing of oils: If header is

to be switched back and forth from combine to

Bi-Directional tractor, change oil in tractor

hydraulic system and in combine adapter

hydraulic reservoir to match combine system.

AVOID HIGH-PRESSURE FLUIDS

CHECK PROPERLY FOR LEAKS

LUBRICATE FLOAT SPRING HARDWARE

A

B