Maintenance/service – MacDon 802 Bi-Directional Adapter User Manual

Page 36

35

MAINTENANCE/SERVICE

GREASING THE ADAPTER

Use an SAE Multi-Purpose High Temperature

Grease with Extreme Pressure (EP) Performance

and containing at least 1.5% molybdenum

disulphide. Also acceptable is an SAE Multi-

Purpose Lithium Base Grease.

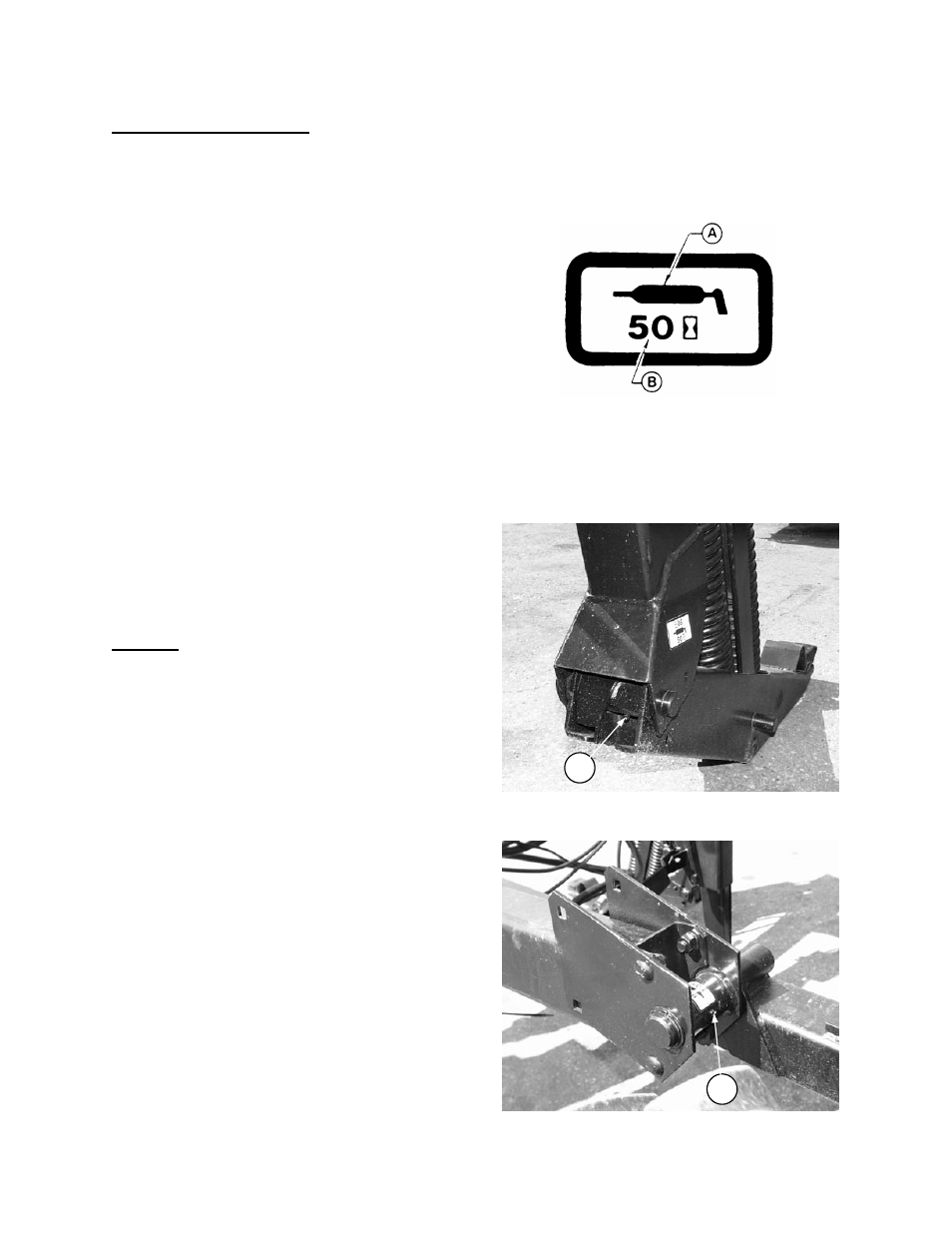

The following greasing points are marked on the

adapter by decals showing a grease gun (A), and

grease interval (B) in hours of operation. Use the

hour meter in the tractor cab and the "Maintenance

Checklist" provided in the Header Operator's

Manual to keep track of scheduled maintenance.

Procedure:

1. Wipe grease fitting with a clean cloth before

greasing, to avoid injecting dirt and grit.

2. Inject grease through fitting with grease gun

until grease overflows fitting.

3. Leave excess grease on fitting to keep out dirt.

4. Replace any loose or broken fittings immedi-

ately.

5. If fitting will not take grease, remove and clean

thoroughly. Also clean lubricant passageway.

Replace fitting if necessary.

50 Hours

1. Lower Link Bushings (C) - two fittings

2. Upper Arm Bushings (D) - two fittings

NOTE: Add these grease points to the

Maintenance Checklist in the Header Operator's

Manual.

SAMPLE GREASE DECAL

LOWER LINK BUSHINGS

C

UPPER ARM BUSHINGS

D