MacDon 872 Combine Adapter User Manual

Page 71

71

SHIM STORAGE

Installing Float Range Limiters for John Deere 50 Series,

Contour Master & New Holland TR Combines

Float range limiter shims must be installed on the adapter

when used with John Deere 50 Series* & Contour Master*

or New Holland TR** Model Combines to prevent damage

to retracting tine drum and/or header side drapers caused

by contact when operating at flat header angles.

* NOTE: John Deere 50 Series and Contour Master have

one float limiter shim per side factory installed.

** NOTE: On the New Holland TR, the tine drum can be

moved back toward the feeder house to reduce the number

of shims required to eliminate the contact noted above. If

this is done, check clearance to the feed chain before

operating. (See initial positioning of tine drum in the

Assembly section.)

Install float range limiter shims as follows:

1. Remove the adapter from the header with the leaf

springs unloaded (stored energy released). Follow the

procedure detailed in Steps 1 – 11 on previous two

pages.

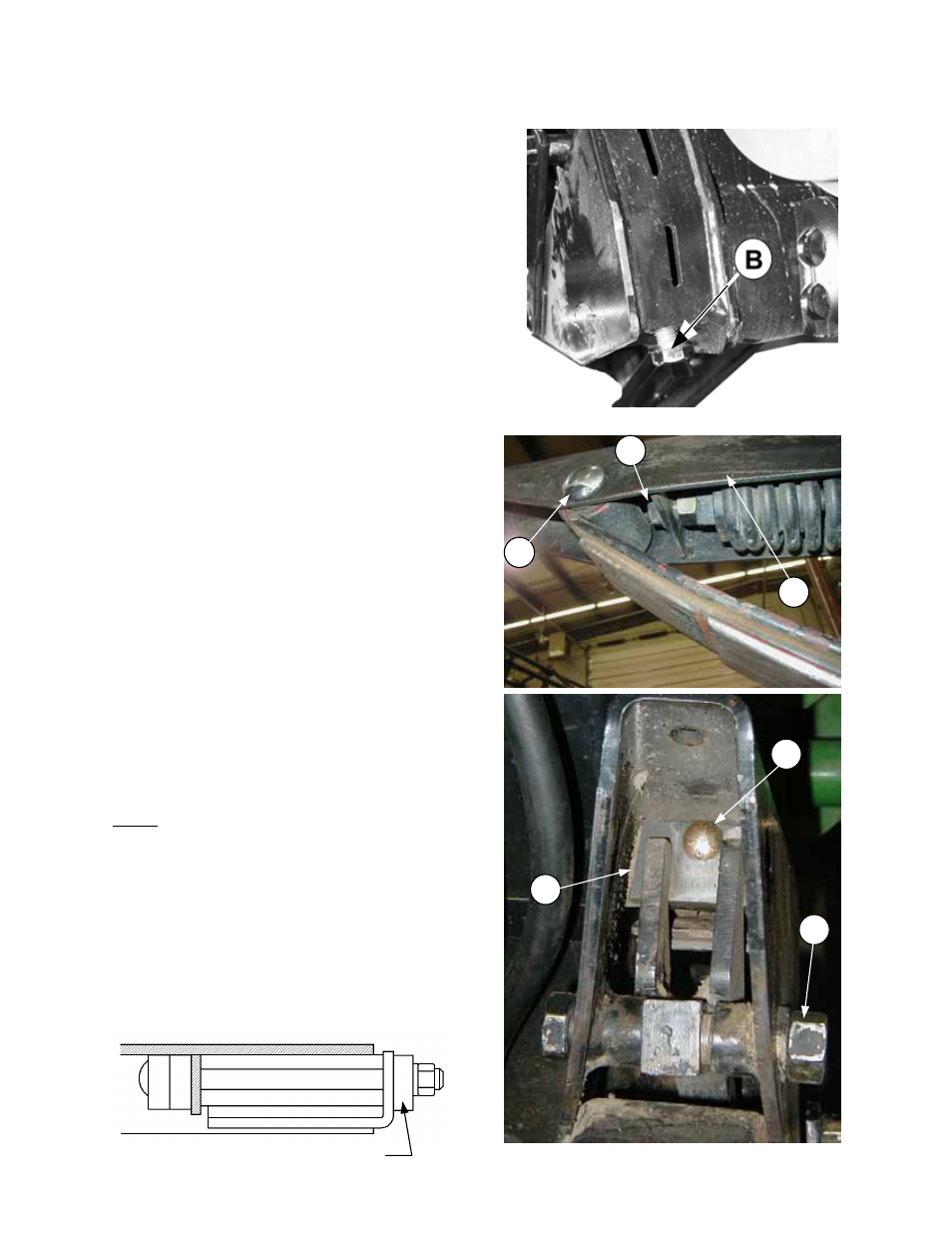

2. Back off the float adjustment screw (B) until

hardware (A) at front of springs loosens.

3. Remove hardware (A), and raise float leg (G) away

from the leaf spring assembly.

4. Loosen coil spring by removing front bolt (C).

5. At back end, remove hardware securing top end of

float arm at (D).

6. Remove 4 ½” long bolt at (E) retaining the angle

which captures the rubber upper stops.

7. Install two or three shims (F) as desired (see note

below for details) and reassemble the upper stop

assembly using the 5 ½” long bolt at (E) in place of

the 4 ½”.

8. Reassemble top end of float arm, ensuring bushing

remains in hole in arm.

9. Reassemble coil spring and leaf springs to float leg.

10. Repeat procedure at other adapter float leg.

11. Engage float lock-out pins by installing adapter into

header or compressing leaf springs. See spring

compression procedure in Tech Manual.

NOTE:

•

Two shims provides 6 inches (150 mm) of float, but when

operating at flat header angles (less than 1” (25 mm) of

thread at both ends of mechanical center link), damage

can occur to the side drapers from contact with the

retracting tine drum supports. This will occur when the

drum is moved forward because of the dust shield on

the feeder house.

•

Three shims limits the float to 4” (100 mm) and ensures

no contact between drum supports and side drapers at

the flattest header angles.

•

If two shims are used, store the third shim between the

nut and upper stop angle as shown below.

E

F

D

A

C

G