Unloading & assembly – MacDon 974 FlexDraper User Manual

Page 83

Form # 147083

Issue 01/07

81

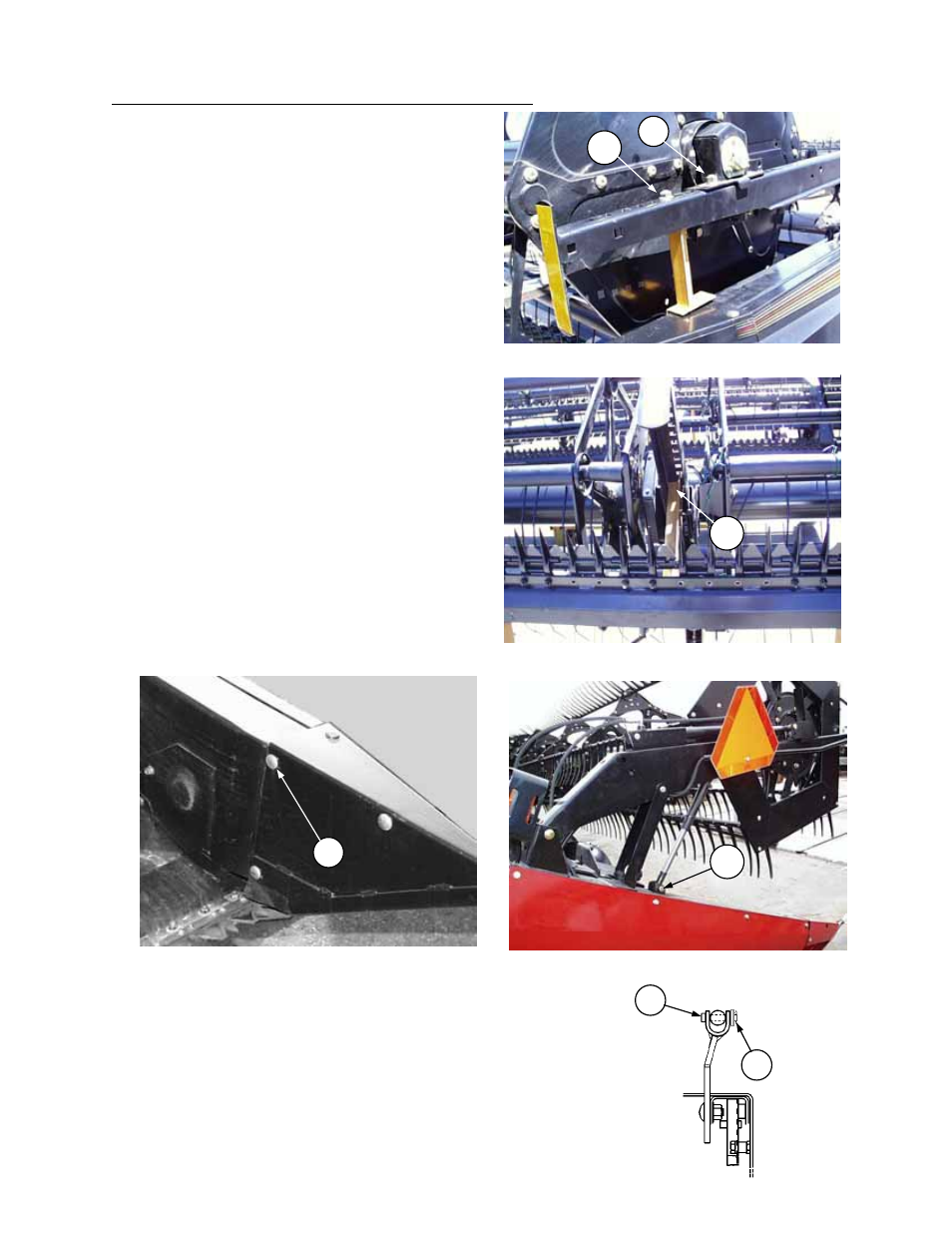

REEL LIFT CYLINDERS WORKING POSITION

B

UNLOADING & ASSEMBLY

REEL SUPPORT ARMS – 30’, 36’ & 39’ Split Reel Headers

1. Drive forklift to front of header, centered on the R/H

reel. Remember L/H and R/H designations are

determined from the rear of the header, facing

forward. Place a lifting strap around reel main tube and

attach to forklift.

NOTE: To avoid damage to tube, do not lift with

forks directly under reel tube.

2. Remove nuts (A) securing yellow shipping supports

to L/H & R/H reel support arms.

3. At center of header, remove nut securing yellow

shipping support (C) to center reel support arm.

4. Raise the forks slowly to raise R/H reel. Engage reel

props at R/H end and center support arms and

lower forks until reel rests on props.

5. Disengage center reel arm shipping support from

cutterbar and discard.

6. Drive the forklift to L/H end of left reel. Place lifting

strap around reel main tube and attach to forklift.

Raise the forks slowly to raise L/H reel. Engage reel

prop at L/H end and lower forks until reel rests on

prop. Back the forklift away.

7. Remove the bolts securing left and right end

shipping supports to header frame. Discard straps

and re-install hardware. Hardware at (F) is installed

reversed for ease of access when removing

shipping supports. To prevent damage to reel end

shields and /or discs, always install carriage head

bolts to the inside of header as shown for field use.

8. Cut shipping wire securing reel lift cylinders. At outer

arms, attach rod end of reel lift cylinder to header

at (B). At center arm, attach rod end of cylinder to

reel support arm. Bleed air from cylinders per

instructions on page 85.

974 Reel Fore-Aft Cylinders:

1. Cut shipping wire securing reel fore-aft cylinders. Prior to attaching fore-

aft cylinders, bleed air per instruction on page 85.

2. After bleeding, attach cylinders to fore-aft supports at end of reel arms. At

center arm, install clevis pin with head at (D) as shown, and use 21/32

ID washer(s) as required to maximize clearance between pin head

and reel end shield. Secure clevis pin with cotter pin (E). Move reel

manually to line up pinholes

3. Remove bolt (G) (see photo top left) securing reel end supports to reel

arms.

CENTER REEL SUPPORT ARM

C

REEL SUPPORT ARMS SHIPPING POSITION

A

G

INSTALL HARDWARE WITH HEADS IN

F

E

D