Operation – MacDon 974 FlexDraper User Manual

Page 25

Form # 147083

Issue 01/07

23

OPERATION

HEADER FLOTATION ADJUSTMENT – 974 FLEX

HEADERS

Cutting on the Ground (Operating Tips continued)

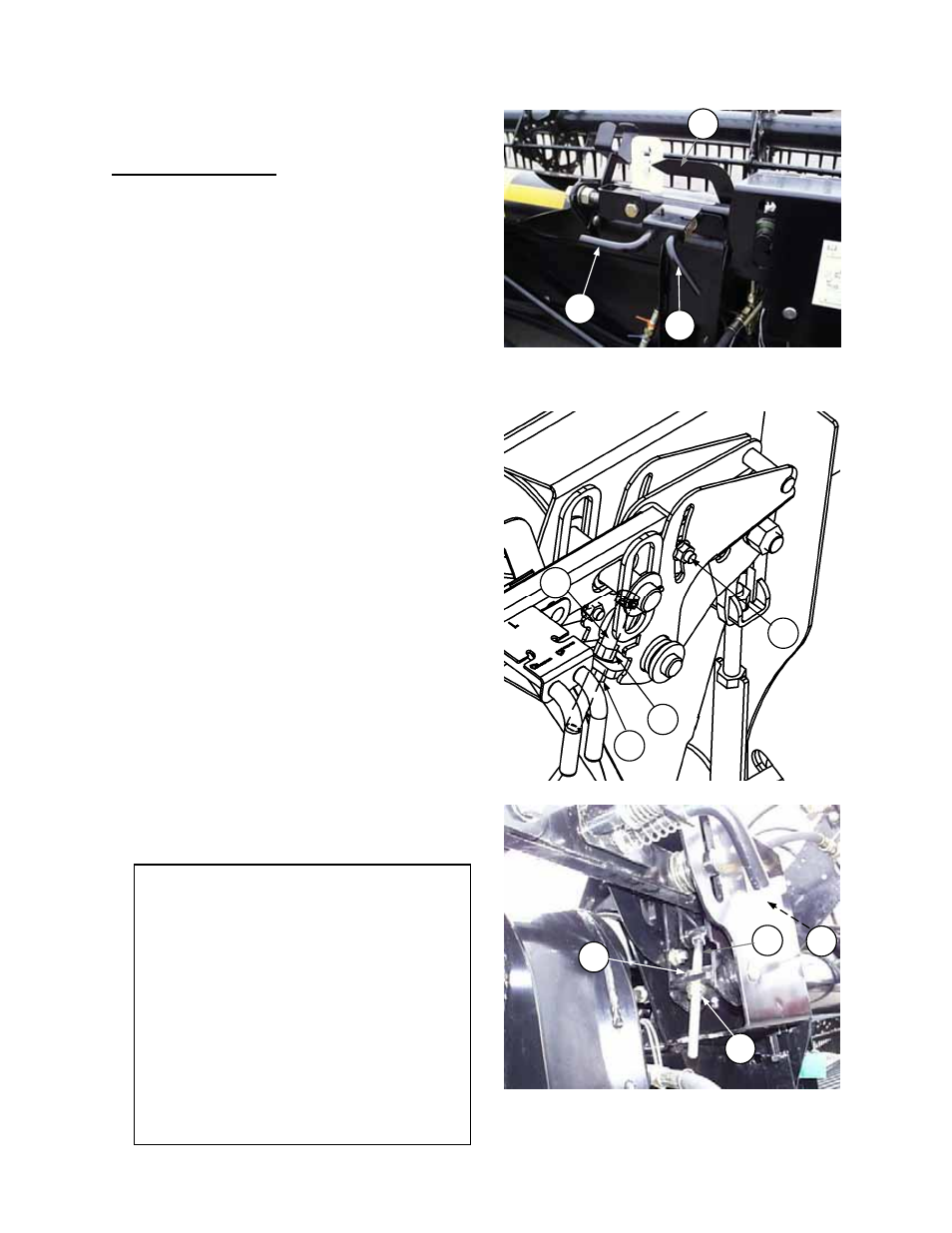

3. Disengage wing float lock pins (Position (B), two

per side) to allow wings to float.

4. Adjust float optimizer while watching float indicator

to set desired cutterbar down force (flotation).

5. Adjust header angle to achieve desired stubble

height. NOTE: Use steps 4 and 5 to fine tune the

header to achieve the shortest stubble height

without pushing dirt

6. In rocky fields, adjust skid shoes down. This raises

guards when operating at the flattest header angle

to minimize scooping rocks.

7. If cutterbar begins to push dirt during operation,

adjust header height (with optimizer or feeder

house height control) to minimize pushing.

8. Header angle and reel fore-aft position can be

changed without significantly effecting header

flotation.

Adjust Wing Downforce To Correct Uneven Float:

1. If stubble at dividers is longer than at center, or if

cutterbar pushes dirt in the center section of the

header, adjust to transfer weight from the center

section to the wings as follows:

• Loosen bell crank clamp bolt (C), located inside bell

crank housing.

• Loosen nut (D) and turn nut (E) to raise bell crank

bolt (F).

• Tighten clamp bolt (C).

• NOTE: Make small adjustments in position of tee

bolt (one or two turns) followed by field test. If the tee

bolt is adjusted more than 10 turns in total, perform

the entire “Wing Float Set-Up” procedure detailed on

page 87.

2. If stubble at center of header is longer than at dividers,

or if cutterbar pushes dirt near the ends of the header,

proceed as in Step 1, but lower the tee bolt to transfer

weight from the wings to the center section.

3. When properly adjusted, the wing float indicators (G)

will be moving continuously, indicating header wings

are flexing between “smile” and “frown”. If not, re-

adjust as required per steps 1 & 2.

B

A

WING FLOAT LOCKOUT:

(A) – ENGAGED / (B) – DISENGAGED

G

ADJUST BELL CRANK BOLT –

UP FOR HEAVIER WING / DOWN FOR

LIGHTER WING

C

D

F

E

NOTE: Functions of inner and outer wing

float lock pins – Each wing of the Flex Header

has an inner and outer float lock-out pin as

shown in top photo above. These pins can be

engaged (as at (A) above) or disengaged (as at

(B) above) with the following results:

• Both pins engaged – Wing float is fully

locked out.

• Inner pin engaged, Outer pin disengaged –

Wing can smile, not frown.

• Outer pin engaged, Inner pin disengaged –

Wing can frown, not smile

• Both pins disengaged – Wing is free to flex

to smile and frown positions.

C

E

F

D