Machine setup and calibration – Multiquip STXD6i_Setup User Manual

Page 19

HTXD6i/STXD6i TROWEL • SETUP, ADJUSTMENTS AND CALIBRATIONS — REV. #1 (01/24/14) — PAGE 19

MACHINE SETUP AND CALIBRATION

Calibration

1. Set sensor zero position default:

a. Ensure that foot pedal is fully released.

b. Read % SENSOR VOLTAGE.

c. Round % Sensor Voltage value to nearest percent

and enter in CALB POINT 1 DEFAULT.

d. Press "Download" button to update value in MCU.

2. Set sensor full position default:

a. Fully depress pedal.

b. Read % Sensor Voltage (Figure 25).

c. Round value to nearest percent and enter in CALB

POINT 2 DEFAULT.

d. Press "Download button" to update value in MCU.

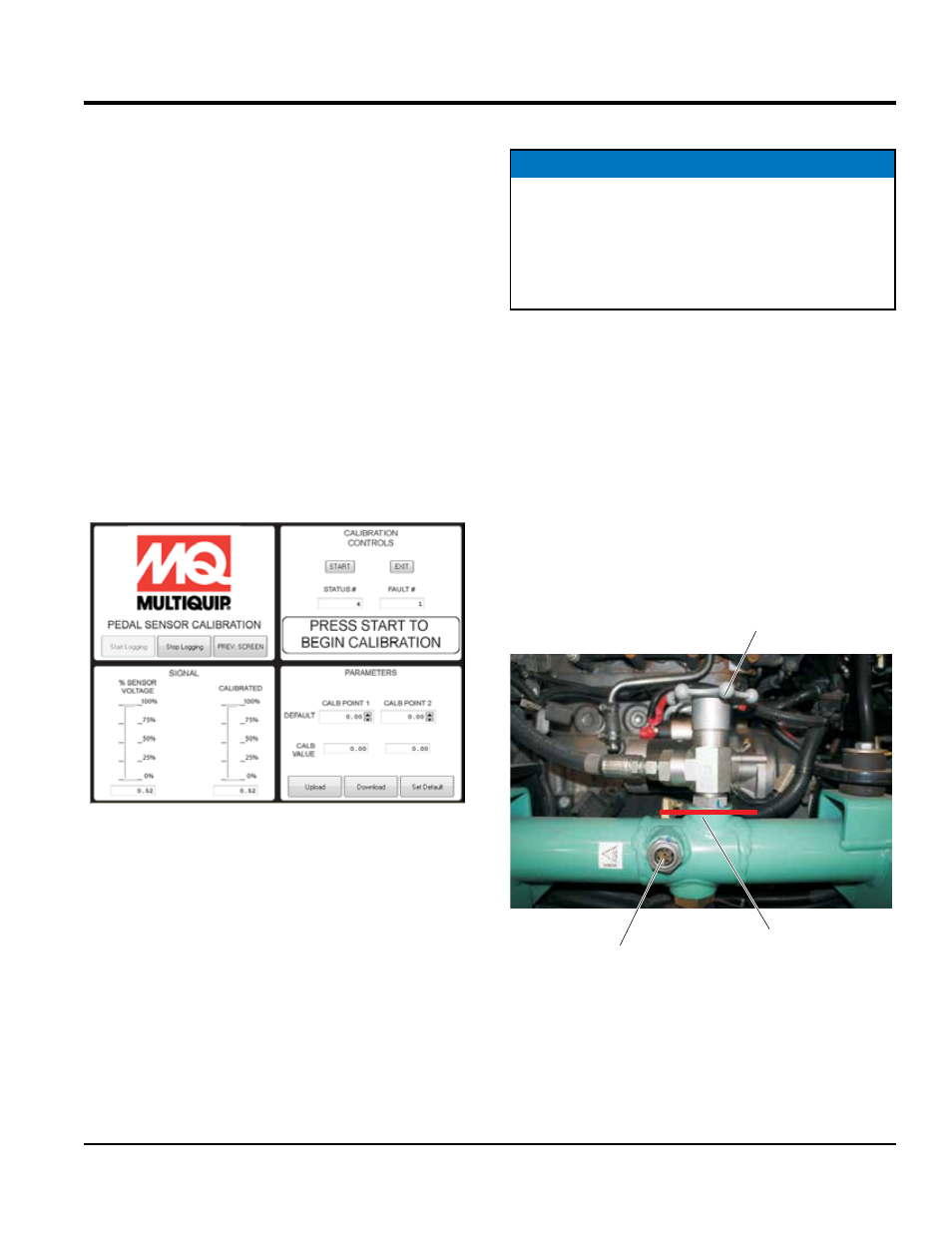

Figure 25. Start Pedal Sensor Calibration

3. Press “START” button to begin calibration and follow

prompts.

4. Once calibrated, move pedal thru range, ensuring

calibrated signal moves from 0 to 100%.

5. Record Calibration Values on Machine Information and

Maintenance Log.

SECONDARY HYDRAULIC FILL PROCEDURES

1. Elevate machine so blades are no longer contacting

floor.

2. Start the unit and run the engine.

3. Check level while machine is cold.

4. Remove the starwheel cap (Figure 6) and visually

check oil level.

5. Fill as needed so oil is at the top line of the reservoir

(red line in Figure 26) and that the oil level cannot be

seen in the fluid condition sight glass.

Figure 26. Checking Oil Level

6. Put back and tighten starwheel cap after filling.

7. Turn off machine and lower.

NOTICE

Once the oil heats up, any oil expansion will go up the

overflow hose and into the fluid expansion tank.

Removing the oil fill cap, once the fluid is at operating

temperature, will cause fluid loss as the expansion will

cause oil to spill out.

FLUID CONDITION

SIGHT GLASS

OIL LEVEL

(FULL)

REMOVE STARWHEEL

CAP TO CHECK OIL LEVEL