Maintenance – Multiquip HHNG5 User Manual

Page 37

HHNg5 RIDe-ON TROWeL • OpeRaTION maNuaL — Rev. #0 (07/16/13) — page 37

MAIntEnAncE

INSTaLLINg paNS ONTO FINISHeR BLaDeS

These round discs sometimes referred to as "pans" attach

to the spiders arms and allow early floating on wet concrete

and easy movement from wet to dry areas. They are also

very effective in embedding large aggregates and surface

hardeners.

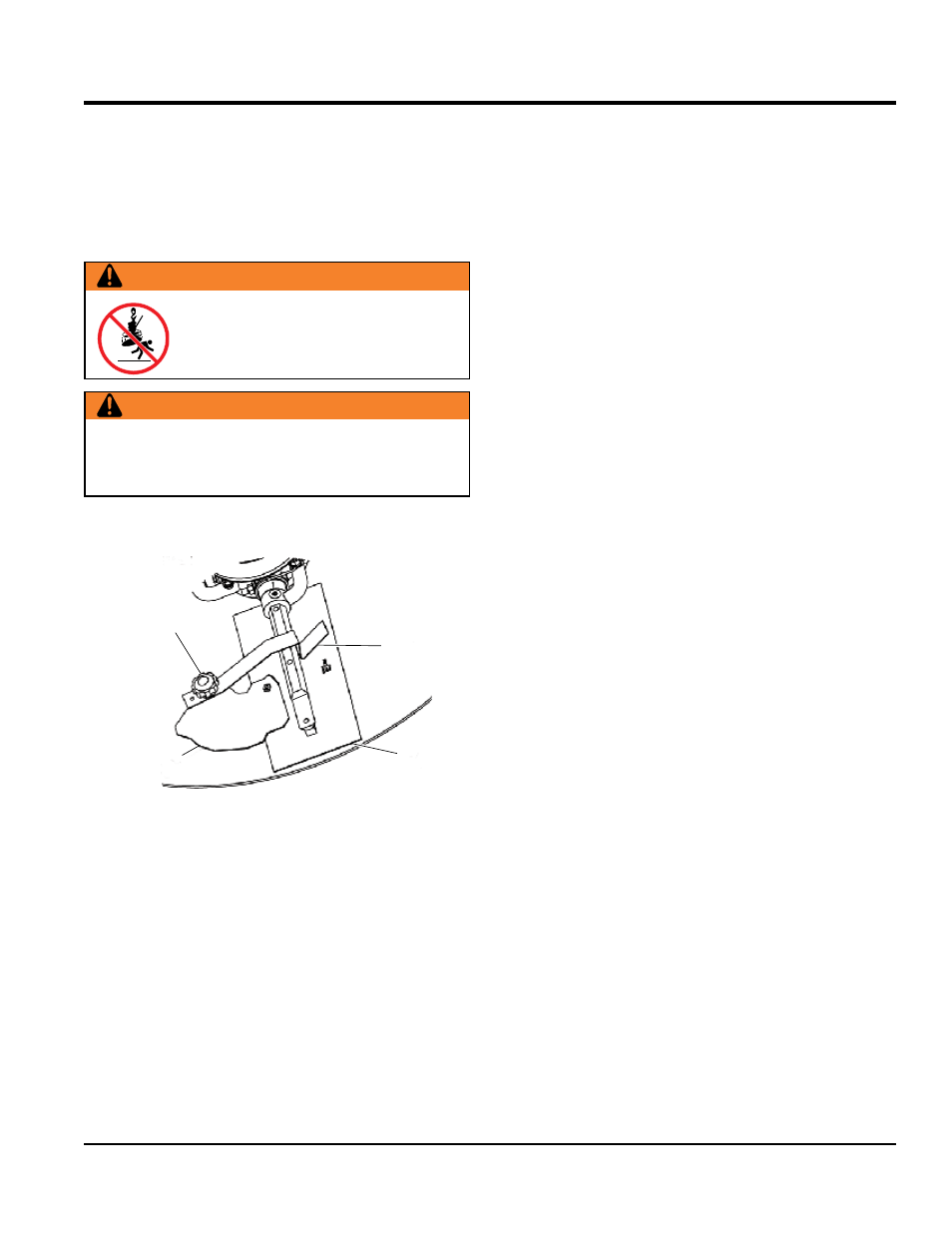

Refer to Figure 43 when installing pans onto finisher blades.

Figure 43. Z-Clip Finisher Pan Installation

wARNiNG

Lifting/Crush Hazard.

dO NOT lift trowel with

pans attached.

wARNiNG

AlwAYS install pans either on the work area or on an

area that is next to and level with the work area.

dO NOT

lift thetrowel when the pans are attached.

BLADE

ASSEMBLY

KNOB, TIE-DOWN

Z-CLIP PANS

TIE-DOWN,

BLADE

Z-CLIP,

PAN

1. Lift trowel just enough to slide pan under blades. Lower

finisher onto pan with blades adjacent to Z-Clips.

2. Rotate blades into position under Z-Clips. Ensure that

the blades are rotated in the direction of travel when

the machine is in operation or use the engine to rotate

the blades into position.

3. Attach the blade tie-downs to the far side of the Z-Clip

brackets with tie-down knobs as shown in Figure 43.

4. Check to make certain that the blade edges are

secured under the Z-Clips and the tie-downs are

secured completely over the edges of the blade bar

before the machine is put back into operation.

DeCOmmISSIONINg TROWeL/COmpONeNTS

Decommissioning is a controlled process used to safely

retire a piece of equipment that is no longer serviceable.

If the equipment poses an unacceptable and unrepairable

safety risk due to wear or damage or is no longer cost

effective to maintain, (beyond life-cycle reliability) and is

to be decommissioned, (demolition and dismantlement),

the following procedure must take place:

1. Drain all fluids completely. These may include oil,

gasoline, hydraulic oil and antifreeze. Dispose of

properly in accordance with local and governmental

regulations. Never pour on ground or dump down

drains or sewers.

2. Remove battery and bring to appropriate facility for lead

reclamation. Use safety precautions when handling

batteries that contain sulfuric acid.

3. The remainder can be brought to a salvage yard or

metal reclamation facility for further dismantling.