Maintenance, Trowel arm adjustment, Spider removal – Multiquip HHNG5 User Manual

Page 33

HHNg5 RIDe-ON TROWeL • OpeRaTION maNuaL — Rev. #0 (07/16/13) — page 33

MAIntEnAncE

Trowel Arm Adjustment

A level, clean area to test the trowel prior to and after is

essential. Any unlevel spots in the floor or debris under the

trowel blades will give an incorrect perception of adjustment.

Ideally, a 5' x 5' three-quarters inch thick, flat steel plate

should be used for testing.

Some indications of poor concrete finishing is incorrect

trowel arm alignment, worn spider bushings or bent trowel

arms:

Does your trowel exhibit the following?

Are blades wearing unevenly? Is one blade completely

worn out while the others look new?

Look at the machine while it is running. Do the guard

rings “rock up and down” relative to the ground?

Does the machine have a perceptible rolling or bouncing

motion when in use?

1. To determine which blades need adjustment, place the

trowel in the test area (three-quarter inch thick plate)

and look for the following conditions:

2. Pitch the blades as flat as possible. The adjustment

bolts should all barely make contact with the lower

wear plate on the spider. If one is not making contact,

adjustment will be necessary (Figure 31).

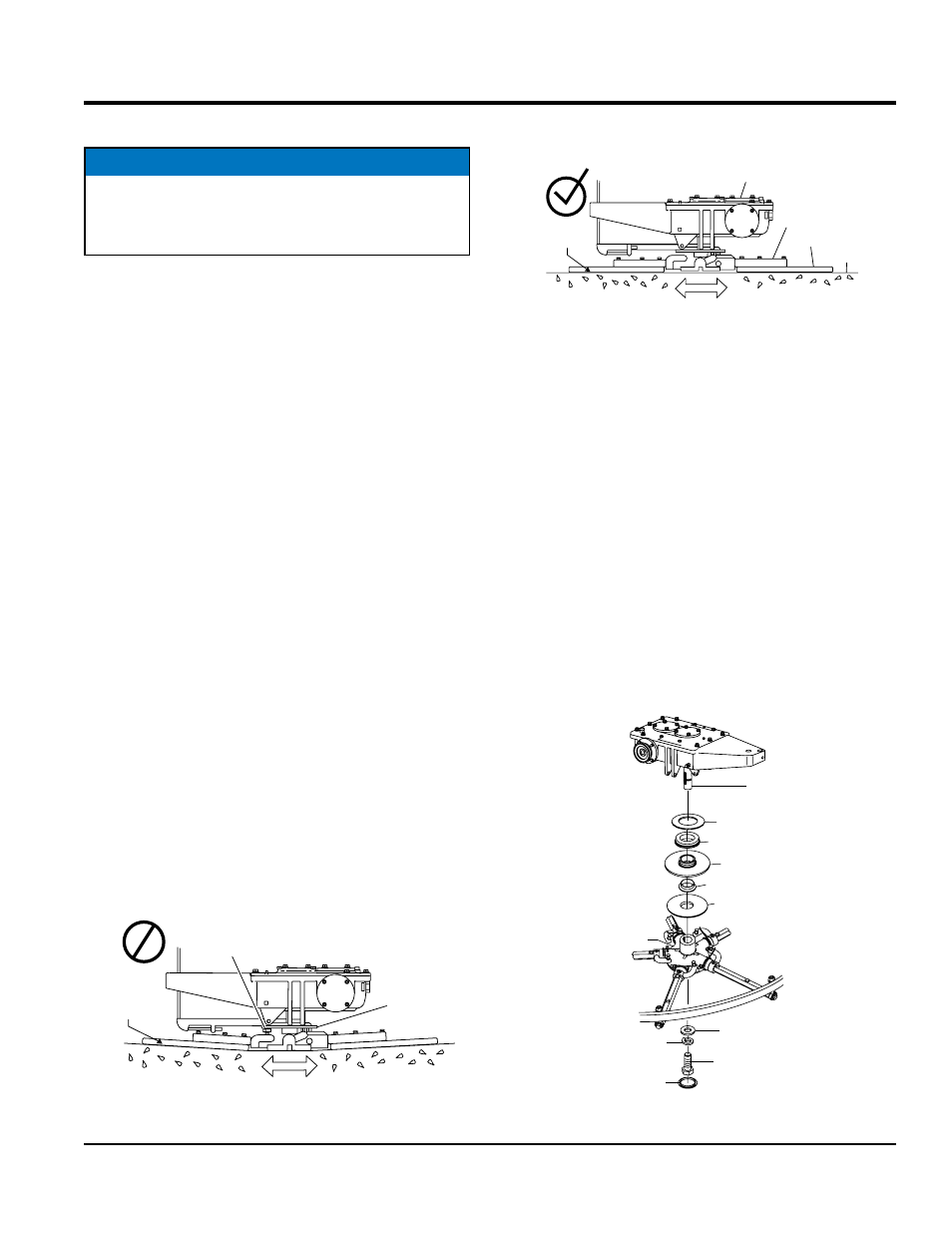

Figure 31 illustrates “incorrect alignment,” worn spider

bushings or bent trowel arms. Check that the adjustment

bolt is barely touching (0.10" max. clearance) lower wear

plate. All alignment bolts should be spaced the same

distance from the lower wear plate.

.

Figure 31. Incorrect Spider Plate Alignment

NOTICE

The following procedure should be followed to adjust

trowel arms when it becomes apparent that the trowel

is finishing poorly or in need of routine maintenance.

ADJUSTMENT BOLT

LOWER

WEAR PLATE

SURFACE

“DISHED”

EFFECT ON

FINISHED

CONCRETE

Figure 32 illustrates the “correct alignment” for a spider

plate (as shipped from the factory).

Figure 32. Correct Spider Plate Alignment

SpIDeR RemOvaL

Remove the spider assembly from the gearbox shaft as

follows:

1. Locate the cone point square head set screw (Figure

33) and attached jam nut found on the side of the

spider assembly.

2. Loosen the jam nut and cone point square head set

screw.

3. Carefully lift the upper trowel assembly off of the spider

assembly. A slight tap with a rubber mallet may be

necessary to dislodge the spider from the main shaft

of the gearbox.

4. For reassembly apply Blue Loctite #242 to the spider

retaining screw and torque to 130 ft.-lbs. (176 N.m)

Figure 33. Spider Removal

GEARBOX

SURFACE

CORRECT

ALIGNMENT

TROWEL

ARM

BLADE

MOUNTING BAR

Upper Wear Plate

Thrust Collar Bearing

Thrust Collar

Thrust Collar Bushing

Lower Wear Plate

Gearbox Shaft

Spider Plate

Retainer

Lock Washer

Retaining Screw

Plug