Maintenance, Trowel arm adjustment – Multiquip HHN34TVD User Manual

Page 40

page 40 — HHN34TVD RIDe-ON TROWeL • OpeRaTION maNuaL — ReV. #2 (01/10/11)

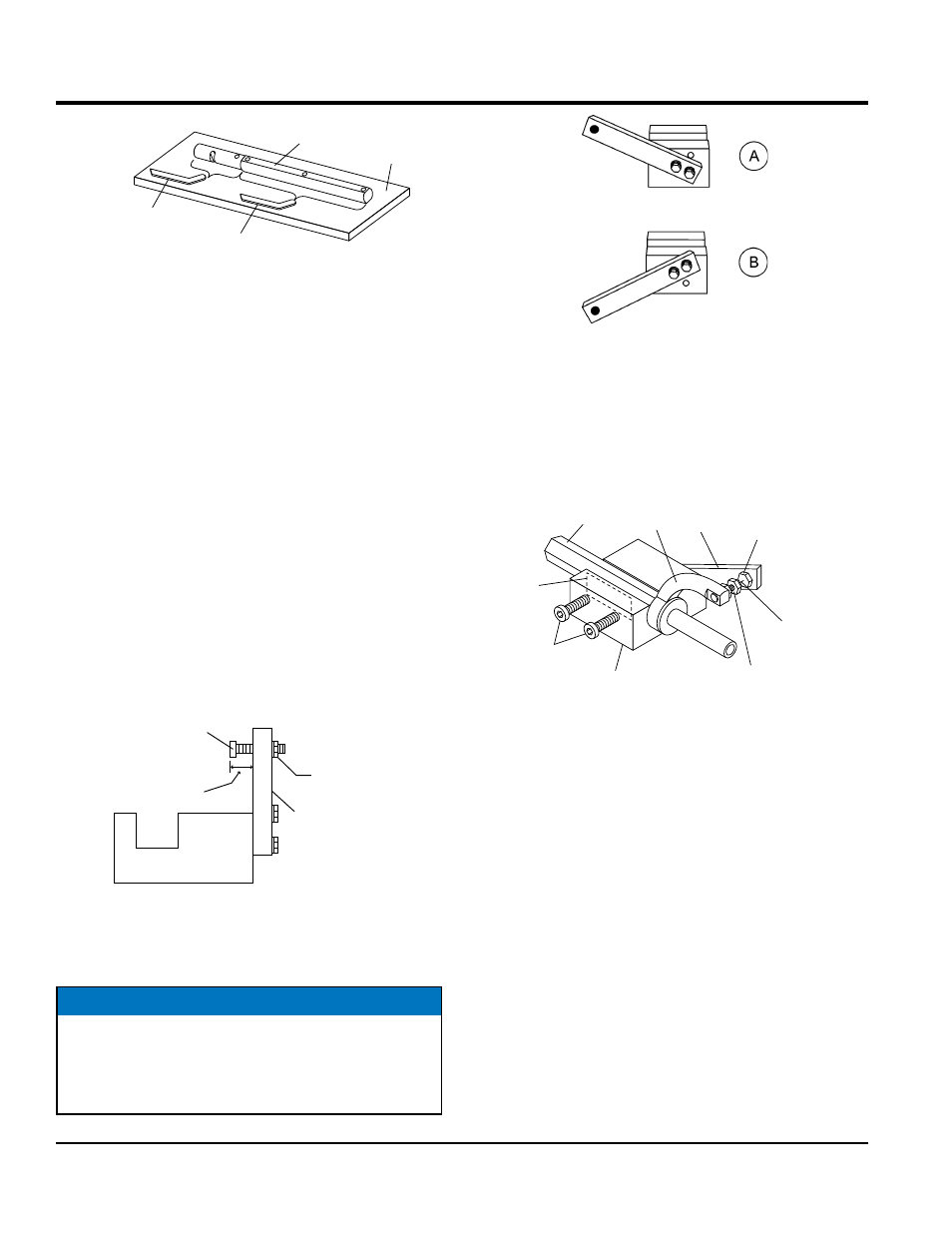

Figure 42. Checking Trowel Arm Flatness

3. Next, check the clearance between the round shaft and

the test surface as one of the flat hex sections of the

arm rests on the test surface. Rotate the arm to each

of the flat hex sections and check the clearance of the

round shaft. Use a feeler gauge of .005" (0.127 mm).

Each section should have the same clearance between

the round of the trowel arm shaft and the test surface.

4. If the trowel arm is found to be uneven or bent, replace

the trowel arm.

TROWeL aRm aDJuSTmeNT

Shown in (Figure 43) is the adjustment fixture with a trowel

arm inserted. As each trowel arm is locked into the fixture,

the arm bolt is adjusted to where it contacts a stop on the

fixture. This will consistently adjust all of the trowel arms,

keeping the finisher as flat and evenly pitched as possible.

1. Locate the trowel arm adjustment tool P/N 9177.

Figure 43. Trowel Arm Adjustment Tool Side View

2. Ensure the fixture arm is in the proper setting (up or down)

for your trowel arm rotation as shown in Figure 44.

TROWEL

ARM

FLAT

TEST

SURFACE

FEELER GAUGE

(.004 in./0.10 mm)

FEELER GAUGE

(.005 in./0.127 mm)

ADJUSTMENT

BOLT

“DISTANCE”

LOCKING

NUT

FIXTURE

ARM

SIDE VIEW

NOTICE

Arms with CLOCK-WISE blade rotation use the fixture arm

in the UP position (Figure 44, A). Arms with COUNTER

CLOCK-WISE blade rotation use the fixture with the fixture

arm in the DOWN position (Figure 44, B).

Maintenance

Figure 44. Trowel Arm Adjustment Setup

3. Unscrew the locking bolts on the adjustment tool and

place the trowel arm into the fixture channel as shown

in Figure 45. A thin shim may be required to cover the

blade holes on the trowel arm. Make sure to align the

trowel adjustment bolt with the fixture adjustment bolt.

Figure 45. Trowel Arm Adjustment Fixture

Components

4. Use an allen wrench to tighten the locking bolts

securing the trowel arm in place.

5. Adjust the bolt “distance” shown in Figure 45to match

one of the arms. The other arms will be adjusted to

match this distance.

6. Loosen the locking nut on the trowel arm lever, then

turn the trowel arm adjusting bolt until it barely touches

(.010") the fixture adjusting bolt.

7. Once the correct adjustment is made, tighten the lock

nut on the trowel arm to lock in place.

8. Loosen locking nuts on the adjustment fixture, and

remove trowel arm.

9. Repeat steps for the remaining trowel arms.

ARM

TROWEL

ARM

LEVER

ADJUSTMENT

BOLT

ADJUSTMENT

BOLT

FIXTURE

ARM

DISTANCE =

.010 in.

TROWEL ARM

ADJUSTMENT

FIXTURE

LOCKING

BOLTS

SHIM