Maintenance, Spider removal, Trowel blade removal – Multiquip HHN34TVD User Manual

Page 38

page 38 — HHN34TVD RIDe-ON TROWeL • OpeRaTION maNuaL — ReV. #2 (01/10/11)

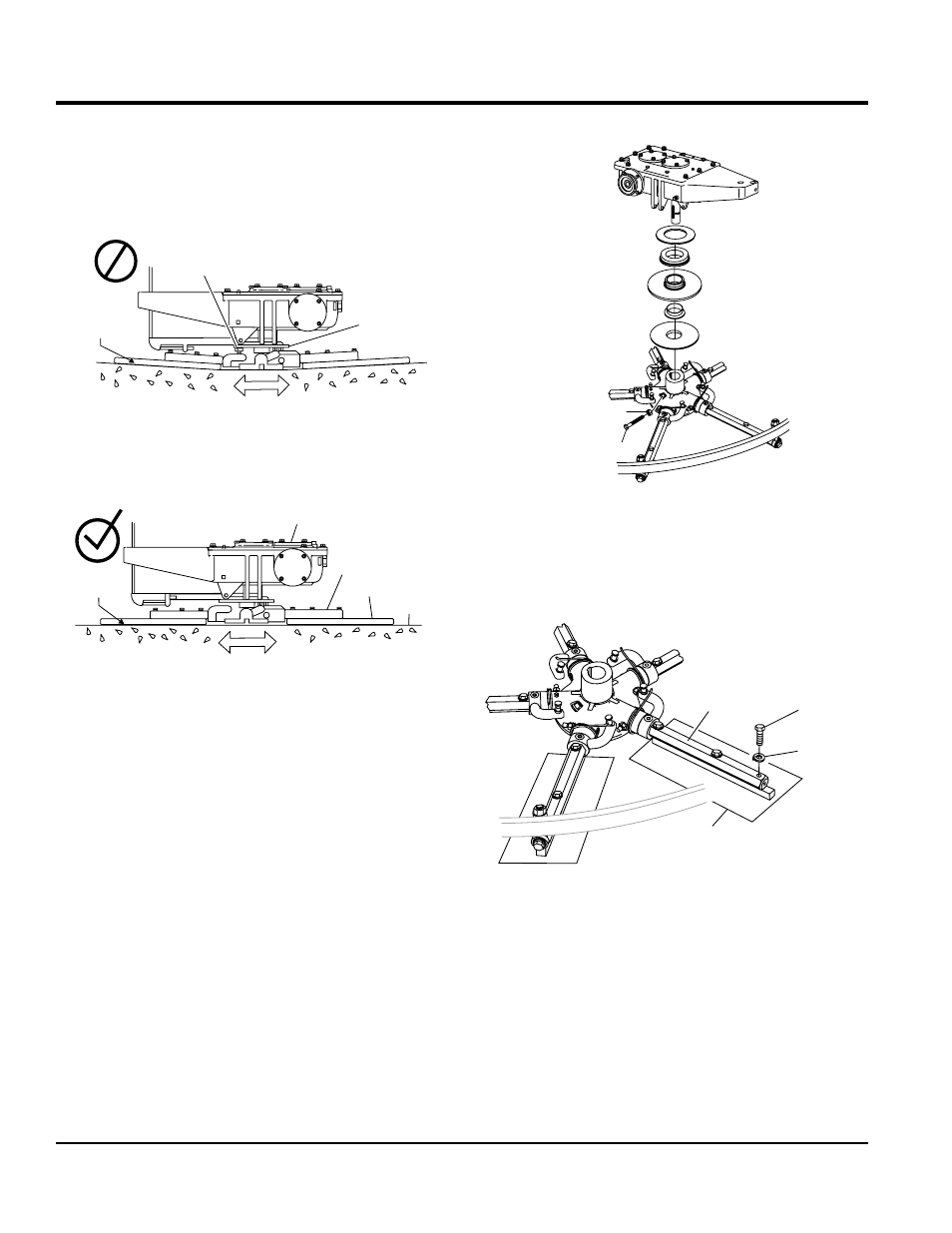

Figure 34 illustrates “incorrect alignment,” worn spider

bushings or bent trowel arms. Check that the adjustment

bolt is barely touching (0.10" max. clearance) lower wear

plate. All alignment bolts should be spaced the same

distance from the lower wear plate.

Figure 34. Incorrect Spider Plate Alignment

Figure 35 illustrates the “correct alignment ” for a spider

plate (as shipped from the factory).

Figure 35. Correct Spider Plate Alignment

SpIDeR RemOVaL

Remove the spider assembly from the gearbox shaft as

follows:

1. Locate the cone point square head set screw (Figure

36) and attached jam nut found on the side of the

spider assembly.

2. Loosen the jam nut and cone point square head set

screw.

3. Carefully lift the upper trowel assembly off of the spider

assembly. A slight tap with a rubber mallet may be

necessary to dislodge the spider from the main shaft

of the gearbox.

ADJUSTMENT BOLT

LOWER

WEAR PLATE

SURFACE

“DISHED”

EFFECT ON

FINISHED

CONCRETE

GEARBOX

SURFACE

CORRECT

ALIGNMENT

TROWEL

ARM

BLADE

MOUNTING BAR

Maintenance

Figure 36. Spider Removal

TROWeL BLaDe RemOVaL

Remove the trowel blades by removing the three hex head

bolts (Figure 37) from the trowel arm. Set blades aside.

Figure 37. Trowel Blade Removal

JAM NUT

GEARBOX

SET SCREW

TROWEL

ARM

TROWEL

BLADE

HEX HEAD

BOLT

LOCK

WASHER