MTS Axial Extensometers User Manual

Page 55

Installation

55

1. The arms of the extensometer must be in the zero reference

position. Depending on the extensometer, this can be accomplished

using the zero pin, stop block, or a special fixture.

The extensometer arms can be damaged when mishandled.

Excessive torque on the extensometer arms can damage the

extensometer.

Use an adjustable wrench to hold the extensometer arm or attachment

adapter. Loosen or tighten only those socket head cap screws on the

arm being held with the wrench. Do not hold the extensometer case

when loosening or tightening the socket head cap screws.

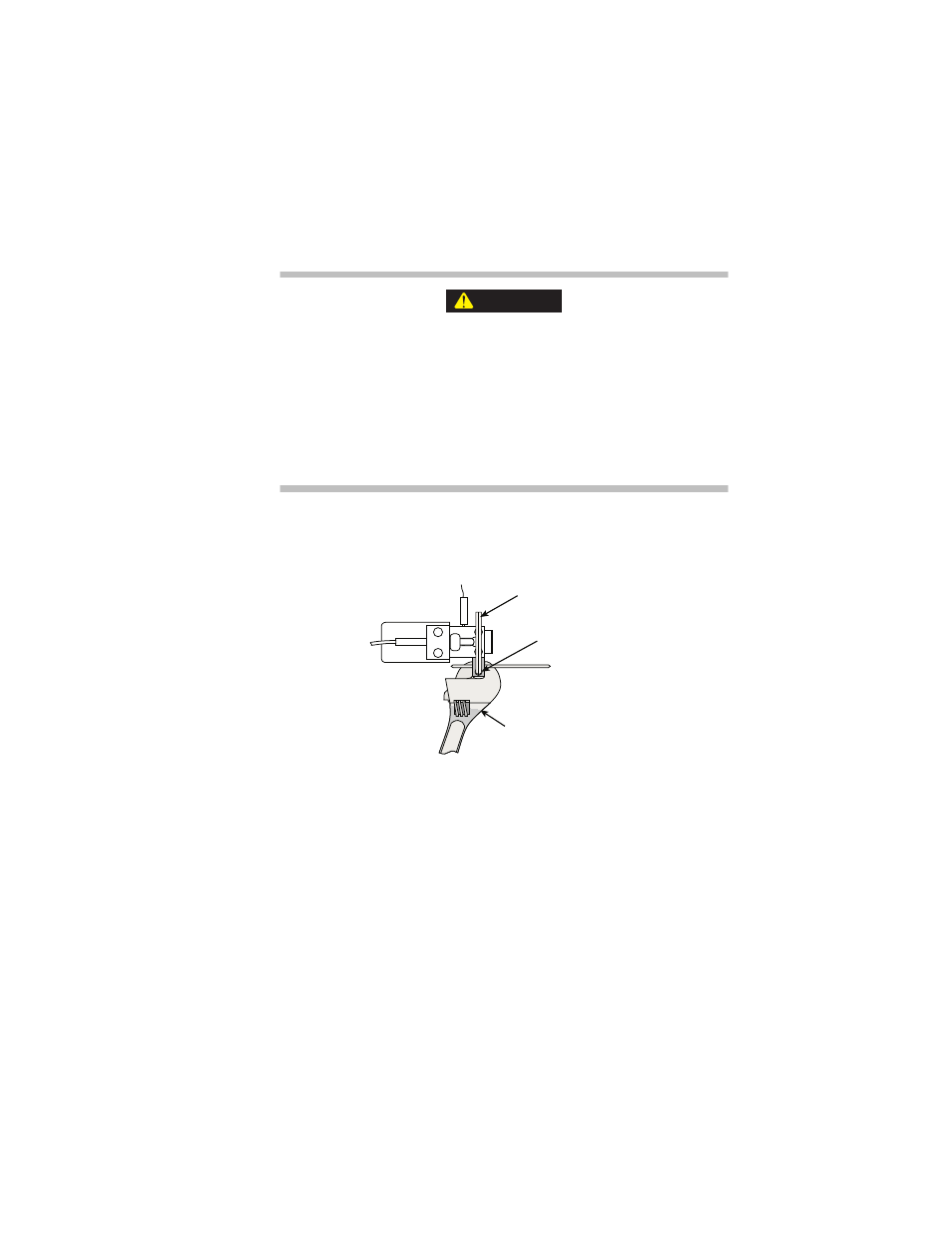

2. Using a small adjustable wrench, grasp the sides of one attachment

adapter.

.

3. While securely holding the attachment adapter, loosen the spring

locking screw on that attachment adapter with a hex wrench.

4. Repeat Step 2 and Step 3 to loosen the spring locking screw on the

other attachment adapter.

5. While measuring the wire end length, slide the spring in or out as

required for the specimen diameter or thickness.

CAUTION

Grasp the attachment

adapter with a small

adjustable wrench

when using the hex

wrench.

Spring

Locking

Screw

Hex Wrench