Standard test area enclosure operation, Hydraulic power off, Specimen installation and setup – MTS Landmark Floor Standing User Manual

Page 71

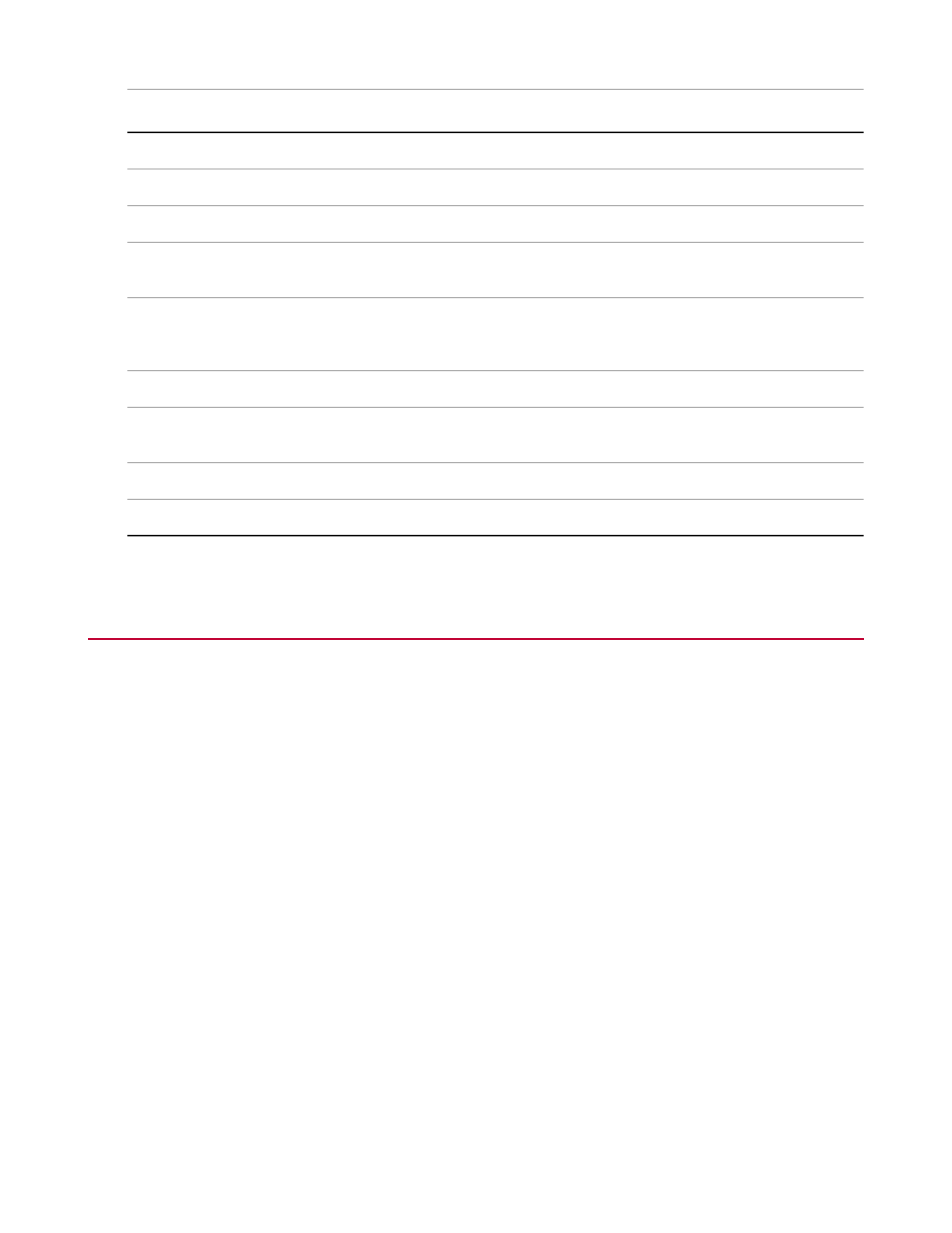

Description

Control/Indicator

Item

RJ-45, to Controller.

Connector

7

Shuts down the HPU.

Hydraulic Off

8

Starts the test action. Only if the application test software is active.

Start

9

Resets active interlock(s) providing the cause for the interlock(s)

has been remedied.

Interlock Reset

10

Press to enable the thumbwheel to position the actuator. Press

again to disable the thumbwheel. The indicator lights when the

thumbwheel is active.

Thumbwheel Enable

11

Indicator. When lit, indicates an active fault or interlock.

Fault

12

Used to enable/disable the handset. When the indicator is lit, the

handset is enabled for control of the actuator.

Handset Enable

13

Selects the highlighted line in the display.

Select (Enter)

14

Four lines, 20 characters per line.

Display

15

Standard Test Area Enclosure Operation

There are four operating modes for an MTS Landmark Test System:

•

Hydraulic Power Off

•

Specimen Installation and Setup

•

Run Mode

•

Service

Hydraulic Power Off

Hydraulic Power is prevented from energizing the circuit via the hydraulic service manifold. Full access to the

test area is allowed in this mode.

Specimen Installation and Setup

The controller provides a means for creating a specimen installation mode. This mode typically uses the

Channel Limited Channel (CLC) control method. The primary control channel is Displacement (stroke) with

maximum limits set on applied force. Tuning parameters unique to this mode optimize manual control during

this mode. In addition, a maximum velocity command is set.

The handset has the ability to have a configuration specific desired response to the thumbwheel encoder on

the handset for a precise level of control.

MTS Landmark™ Floor Standing Load Units Product Information 71

Operation