Sideload calculation procedure, Sideload calculation procedure 33 – MTS Series 242 Actuators User Manual

Page 33

Sideload Calculation Procedure

Series 242 Actuator Product Information

Operation

33

•

Minimum allowable sideload frequency

Sideload Calculation Procedure

The following procedure provides you with information to determine the

suitability of a particular actuator model for tests requiring nonaxial loading.

Some of the constants used in this procedure are defined in the steps and others

are listed in the following table.

Note

The examples included in this procedure assume that the values of F

and P are measured in pounds force and that B, C, and S (stroke) are

measured in inches.

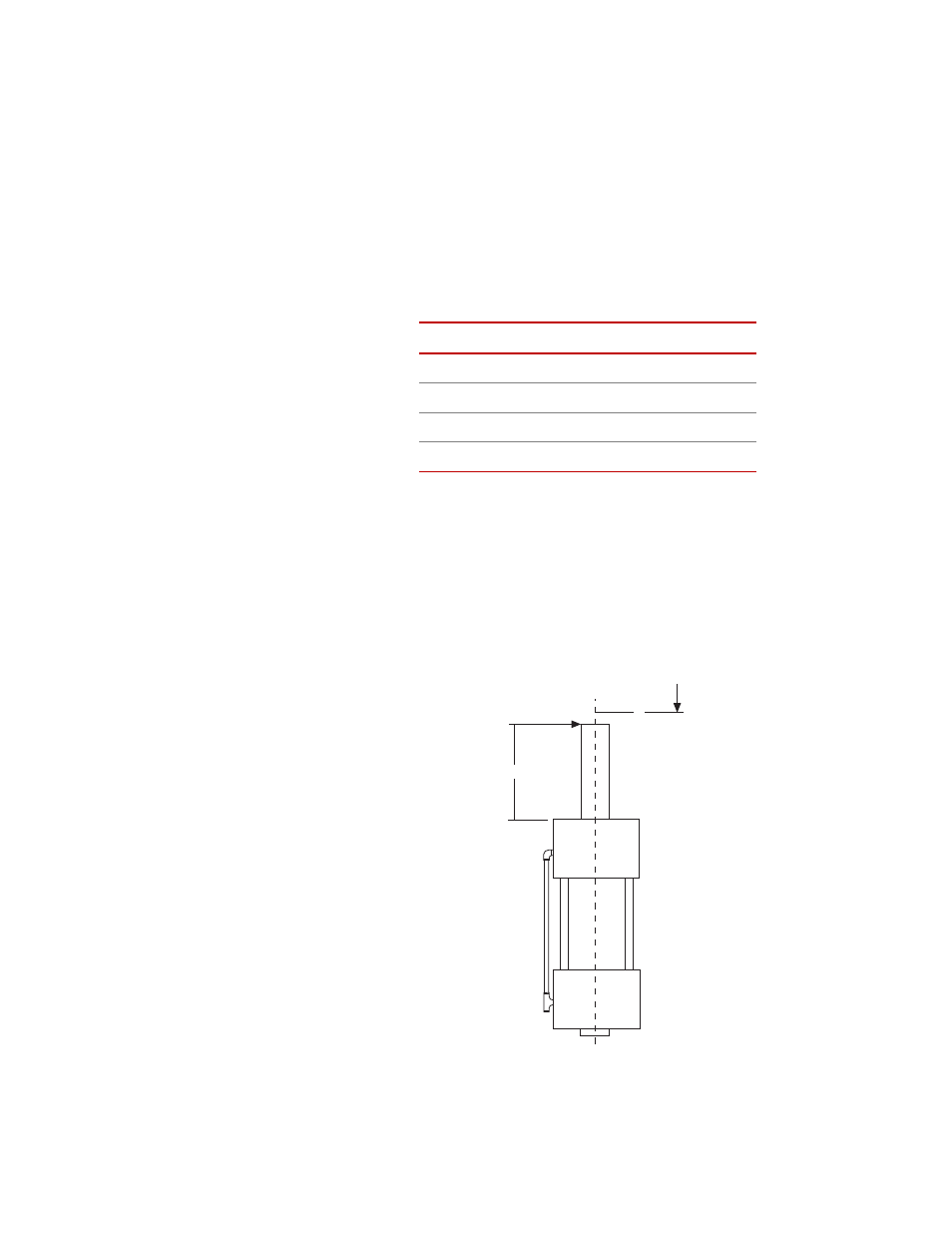

1. Determine the magnitude of nonaxial loads F and P and the point of

application of these loads (B and C respectively). These parameters are

dependent on the test setup configuration. If any parameter is variable

during the test, use the maximum values.

2. Calculate the actuator bearing load (L) using the following formula:

Sideload Constants

S

TROKE

(S)

B

EARING

S

PACING

(A)

25.4 mm (1 in)

96.8 mm (3.82 in)

50.8 mm (2 in)

96.8 mm (3.82 in)

76.2 mm (3 in)

109.5 mm (4.31 in)

101.6 mm (4 in)

109.5 mm (4.31 in)

B

F

P

C

Sideload Forces