242 actuator operating considerations, 242 actuator operating considerations 32 – MTS Series 242 Actuators User Manual

Page 32

Series 242 Actuator Product Information

32

242 Actuator Operating Considerations

Operation

242 Actuator Operating Considerations

Piston rod banding

Piston rod banding can occur if the actuator is operated for a long period of time

at a moderate to high frequency, with short stroke displacement and loads of 25%

or more of the actuator capacity. Piston rod banding is the aggravated erosion of

the piston rod chrome plating in a band slightly wider than the width of the seal

encircling the circumference of the piston rod.

If the actuator is being used for this type of testing, the starting position of the

actuator piston rod should be changed approximately every one million cycles.

This will extend the life of the piston rod and minimize the possibility of

banding. If the system configuration allows it, the piston rod starting position can

be changed by using the displacement transducer conditioner zero control and

repositioning the load frame crosshead or fixture.

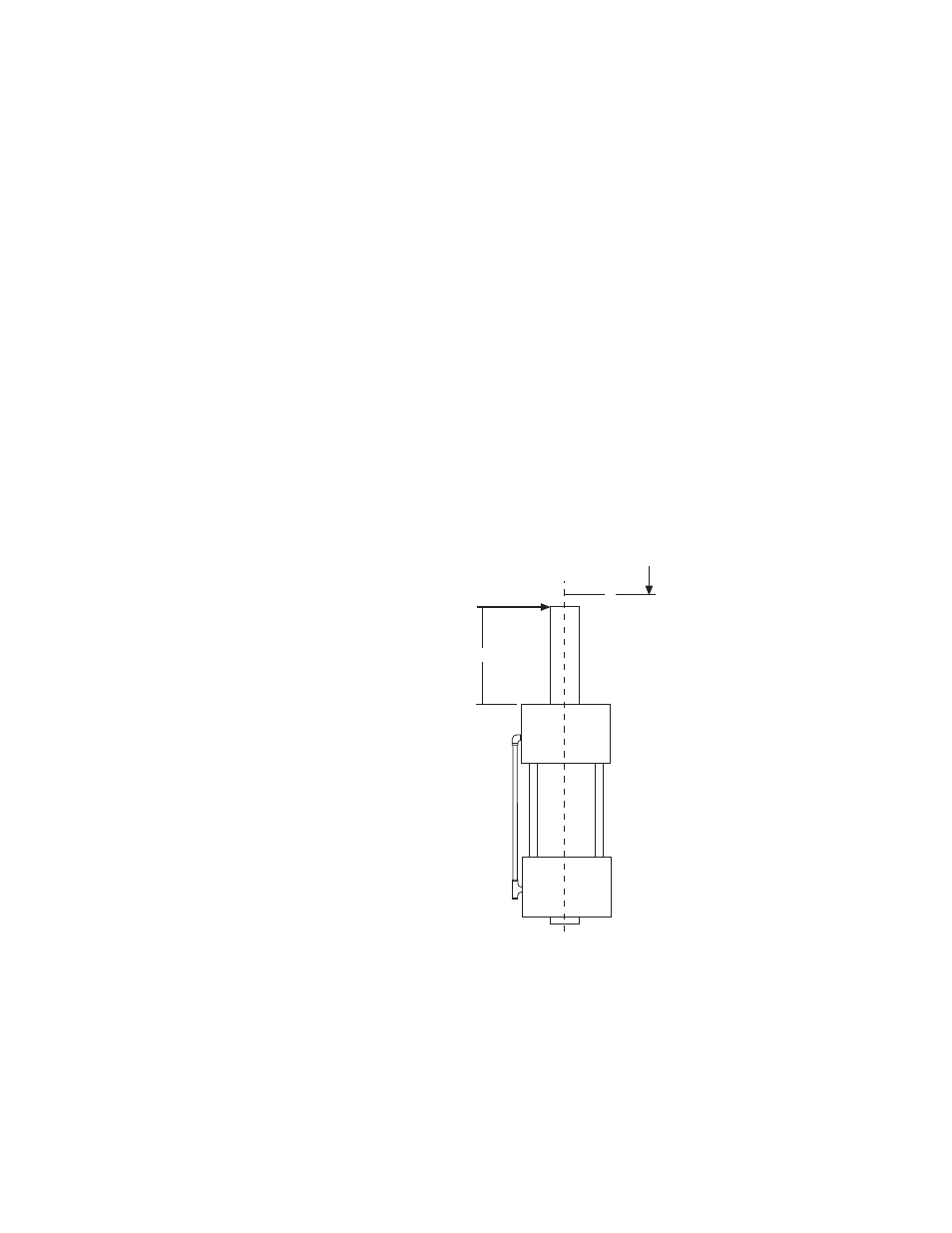

Sideload forces

To avoid damaging the actuator bearings and to ensure proper actuator operation,

tests that subject the actuator to nonaxial loads require special consideration.

Nonaxial loading can occur from sideload forces applied directly to the piston

rod (P in the figure) and from moments caused by off-center loads (F in the

figure).

There are four things that must be considered to determine the suitability of an

actuator for nonaxial loaded tests:

•

Bearing pressure generated during the test

•

Piston rod stress caused by sideload

•

Maximum allowable piston rod velocity

B

F

P

C

Sideload Forces