MK Diamond Baldor Motor User Manual

Page 28

3-6 Maintenance & Troubleshooting

MN408

Suggested bearing and winding RTD setting guidelines for Non−Hazardous Locations ONLY

Most large frame AC Baldor motors with a 1.15 service factor are designed to operate below a Class B

(80 ºC) temperature rise at rated load and are built with a Class H winding insulation system. Based on this

low temperature rise, RTD (Resistance Temperature Detectors) settings for Class B rise should be used as a

starting point. Some motors with 1.0 service factor have Class F temperature rise.

The following tables show the suggested alarm and trip settings for RTDs. Proper bearing and winding RTD

alarm and trip settings should be selected based on these tables unless otherwise specified for specific

applications.

If the driven load is found to operate well below the initial temperature settings under normal conditions, the

alarm and trip settings may be reduced so that an abnormal machine load will be identified.

The temperature limits are based on the installation of the winding RTDs imbedded in the winding as specified

by NEMA. Bearing RTDs should be installed so they are in contact with the outer race on ball or roller bearings

or in direct contact with the sleeve bearing shell.

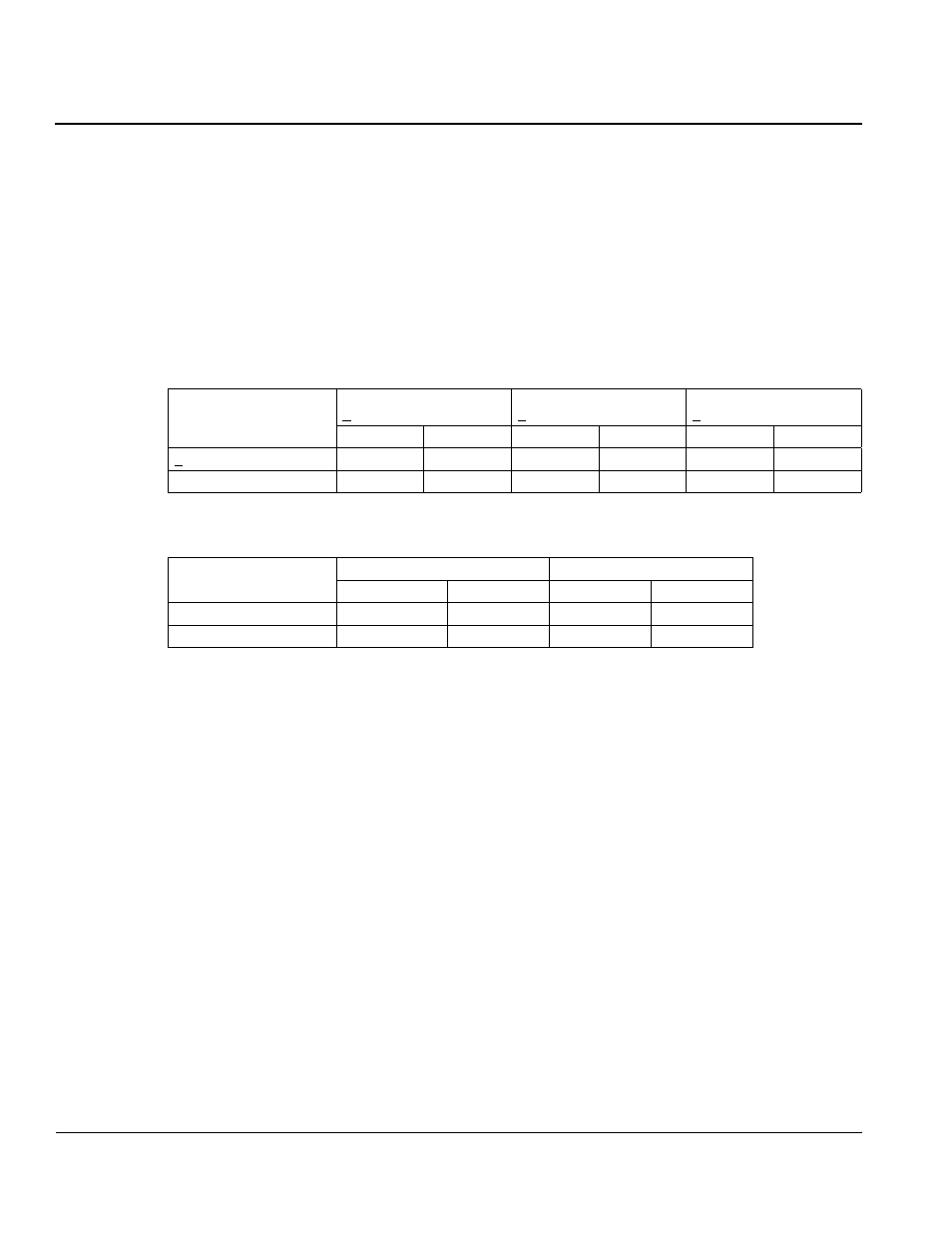

Table 3-7 Winding RTDs − Temperature Limit In ºC (40 ºC Maximum Ambient)

Motor Load

(Typical Design)

Class B Temp Rise

< 80 ºC

Class F Temp Rise

< 105 ºC

Class H Temp Rise

< 125 ºC

Alarm

Trip

Alarm

Trip

Alarm

Trip

< Rated Load

130

140

155

165

175

185

Rated Load to 1.15 S.F.

140

150

160

165

180

185

Note: • Winding RTDs are factory production installed, not from Mod−Express.

When Class H temperatures are used, consider bearing temperatures and relubrication requirements.

Table 3-8 Bearing RTDs − Temperature Limit In oC (40 ºC Maximum Ambient)

Bearing Type Oil or

Grease

Anti−Friction

Sleeve

Alarm

Trip

Alarm

Trip

Standard*

95

100

85

95

High Temperature**

110

115

105

110

Notes: * Bearing temperature limits are for standard design motors operating at Class B temperature rise.

** High temperature lubricants include some special synthetic oils and greases.

Greases that may be substituted that are compatible with Polyrex EM (but considered as “standard” lubricants

include the following:

− Texaco Polystar

− Rykon Premium #2

− Chevron SRI #2

− Mobilith SHC−100

− Pennzoil Pennzlube EM−2

− Chevron Black Pearl

− Darmex 707

− Darmex 711

− Petro−Canada Peerless LLG

See the motor nameplate for replacement grease or oil recommendation.

Contact Baldor application engineering for special lubricants or further clarifications.