MK Diamond Baldor Motor User Manual

Page 12

2-2 Installation & Operation

MN428

Frame Mounting Holes

Some motors have standardized frames containing 6 or 8 mounting holes. 6 hole frames are not suitable for

field reversal of mounting from F−1 to F−2, etc. Figure 2-1 indicates the proper mounting holes to use.

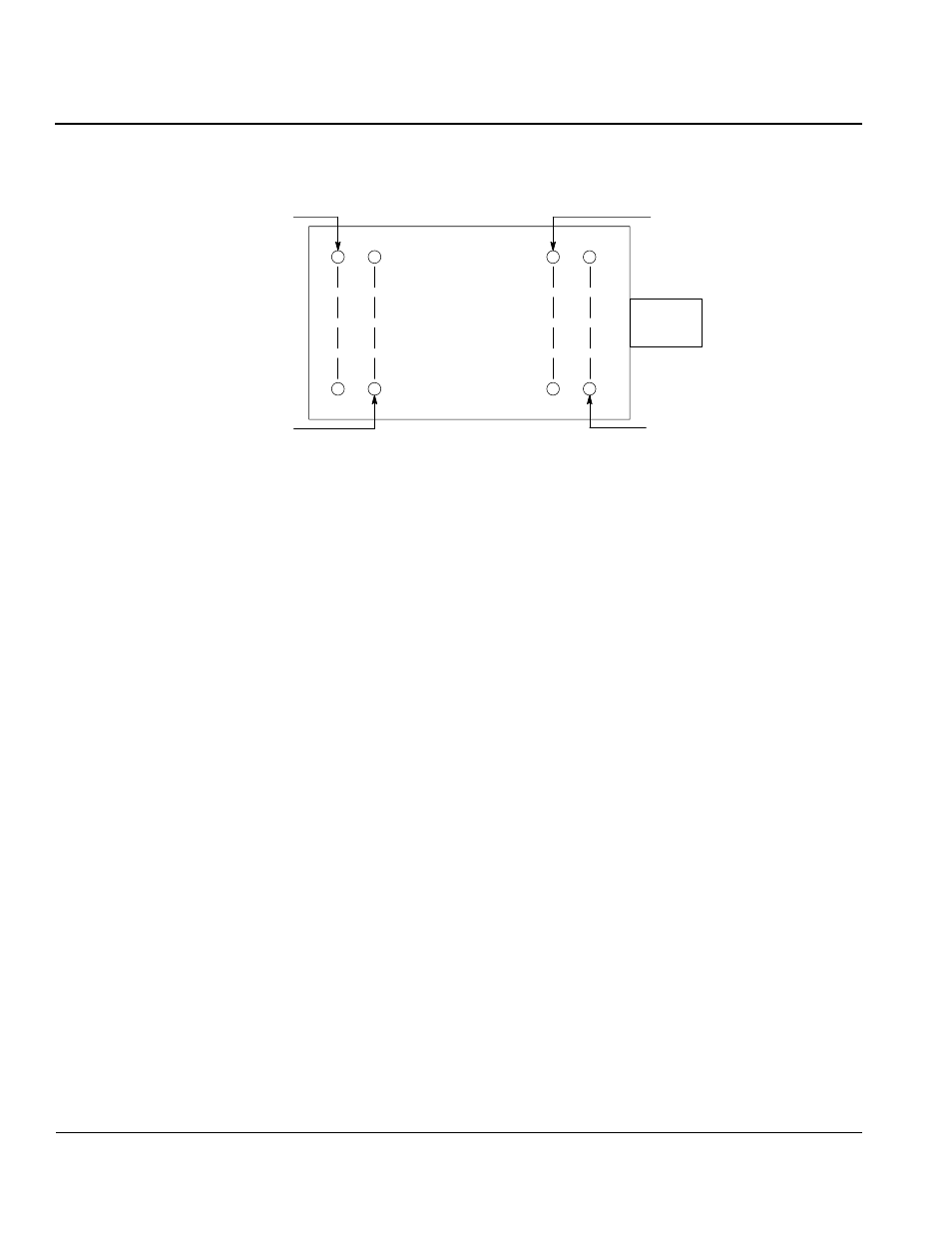

Figure 2-1 6 & 8 Hole Motor Frame Mounting

Caution:

Do not lift the motor and its driven load by the motor lifting hardware. The motor lifting hardware is

adequate for lifting only the motor. Disconnect the load (gears, pumps, compressors, or other driven

equipment) from the motor shaft before lifting the motor.

In the case of assemblies on a common base, any lifting means provided on the motor should not be used

to lift the assembly and base but, rather, the assembly should be lifted by a sling around the base or by other

lifting means provided on the base. Assure lifting in the direction intended in the design of the lifting means.

Likewise, precautions should be taken to prevent hazardous overloads due to deceleration, acceleration or

shock forces.

Alignment

Accurate alignment of the motor with the driven equipment is extremely important. The pulley, sprocket,

or gear used in the drive should be located on the shaft as close to the shaft shoulder as possible. It is

recommended to heat the pulley, sprocket, or gear before installing on the motor shaft. Forcibly driving a unit

on the motor shaft will damage the bearings.

1. Direct Coupling

For direct drive, use flexible couplings if possible. Consult the drive or equipment manufacturer for more

information. Mechanical vibration and roughness during operation may indicate poor alignment. Use dial

indicators to check alignment. The space between coupling hubs should be maintained as recommended

by the coupling manufacturer.

2. End-Play Adjustment

The axial position of the motor frame with respect to its load is also extremely important. The standard

motor bearings are not designed for excessive external axial thrust loads. Improper adjustment will cause

failure.

3. Pulley Ratio

The best practice is to not exceed an 8:1 pulley ratio.

Caution:

Do not over tension belts. Excess tension may damage the motor or driven equipment.

4. Belt Drive

Align sheaves carefully to minimize belt wear and axial bearing loads (see End-Play Adjustment). Belt

tension should be sufficient to prevent belt slippage at rated speed and load. However, belt slippage may

occur during starting.

Doweling & Bolting

After proper alignment is verified, dowel pins should be inserted through the motor feet into the foundation.

This will maintain the correct motor position should motor removal be required.

(Baldor•Reliance motors are designed for doweling.)

1. Drill dowel holes in diagonally opposite motor feet in the locations provided.

2. Drill corresponding holes in the foundation.

3. Ream all holes.

4. Install proper fitting dowels.

5. Mounting bolts must be carefully tightened to prevent changes in alignment.

Top View

Allows F-1 to F-2 Conversion on 8 hole

frames.

Not present on 6 hole frames.

Not used on 8 hole frames.

Shaft

Always use these holes, closer to the

shaft 112S, 132S, 160M, 180M,

200M, 225S, 250S, 280S, (IEC)

For short frame designations 182, 213,

254, 284, 324, 364, 404, 444 (NEMA)

For long frame designations 184, 215,

256, 286, 326, 365, 405, 445 (NEMA)

(IEC) 112M, 132M, 160L, 200L, 225M,

250M, 280M