MK Diamond Baldor Motor User Manual

Page 14

2-4 Installation & Operation

MN428

AC Power

Motors with flying lead construction must be properly terminated and insulated.

Connect the motor leads as shown on the connection diagram located on the name plate or inside the cover

on the conduit box. Be sure the following guidelines are met:

1. AC power is within +10% of rated voltage with rated frequency. (See motor name plate for ratings).

OR

2. AC power is within +5% of rated frequency with rated voltage.

OR

3. A combined variation in voltage and frequency of +10% (sum of absolute values) of rated values, provided

the frequency variation does not exceed +5% of rated frequency.

Performance within these voltage and frequency variations are shown in Figure 2-3.

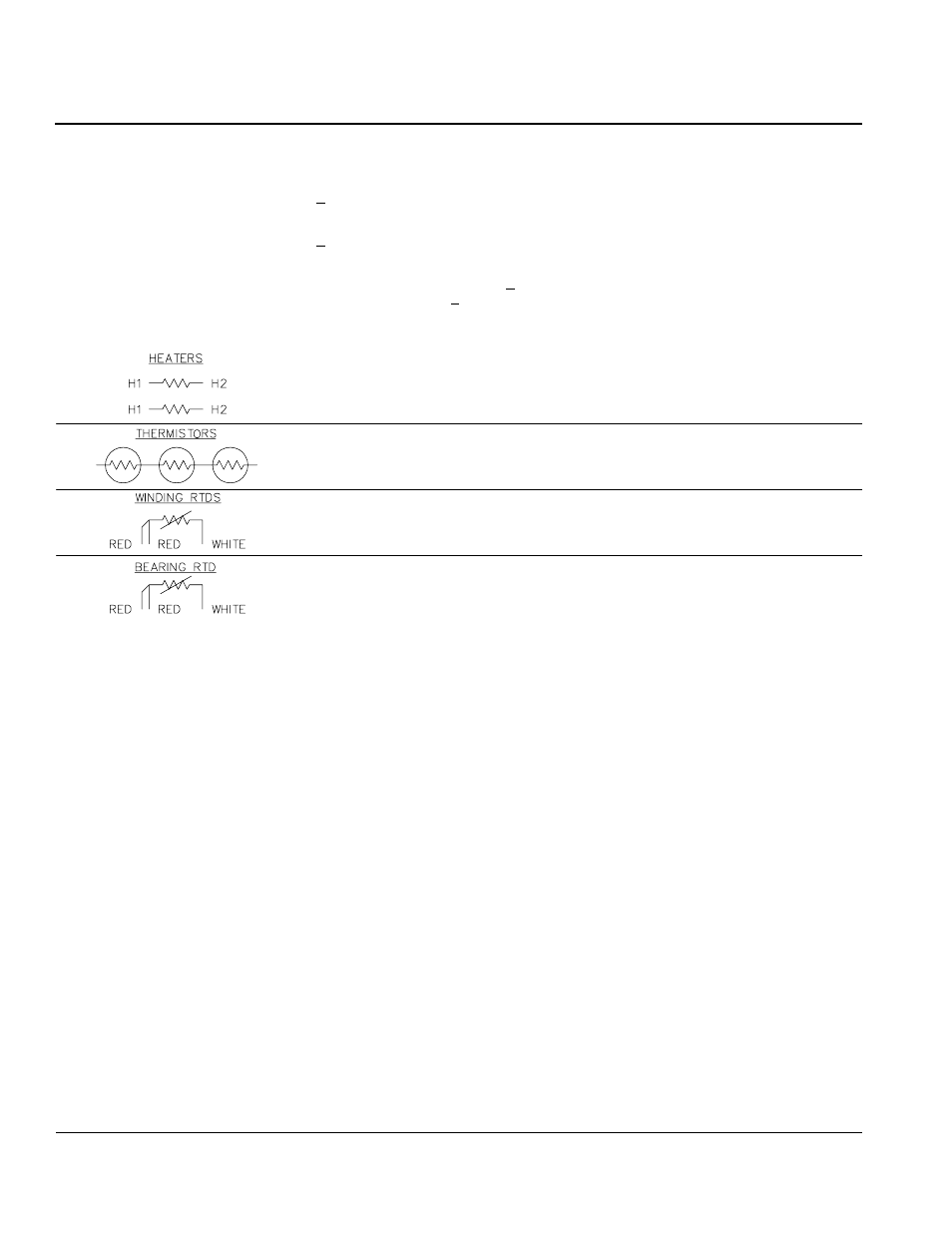

Figure 2-2 Accessory Connections

Rotation

All three phase motors are reversible. To reverse the direction of rotation, disconnect and lock out power

and interchange any two of the three line leads for three phase motors. For single phase motors, check the

connection diagram to determine if the motor is reversible and follow the connection instructions for lead

numbers to be interchanged. Not all single phase motors are reversible.

Adjustable Frequency Power Inverters used to supply adjustable frequency power to induction motors produce

wave forms with lower order harmonics with voltage spikes superimposed. Turn−to−turn, phase−to−phase,

and ground insulation of stator windings are subject to the resulting dielectric stresses. Suitable precautions

should be taken in the design of these drive systems to minimize the magnitude of these voltage spikes.

Consult the drive instructions for maximum acceptable motor lead lengths, and proper grounding.

Note: Main power leads for CE Marked Motors may be marked U,V,W – for standard configurations,

please consult connection diagrams.

Caution:

The space heaters are designed to operate at or below the maximum surface temperature stated on the

nameplate. If the marked ambient and/or voltage are exceeded this maximum surface temperature can

be exceeded and can damage the motor windings. If applied in a division 2 or zone 2 environment this

excessive temperature may cause ignition of hazardous materials.

One heater is installed in each end of motor.

Leads for each heater are labeled H1 & H2.

(Like numbers should be tied together).

Three thermistors are installed in windings and tied in series.

Leads are labeled TD1 & TD2.

Winding RTDs are installed in windings (2) per phase.

Each set of leads is labeled

1TD1, 1TD2, 1TD3, 2TD1, 2TD2, 2TD3 etc

.

* One bearing RTD is installed in Drive endplate (PUEP), leads

are labeled RTDDE.

* One bearing RTD is installed in Opposite Drive endplate (FREP), leads

are labeled RTDODE.

* Note RTD may have 2−Red/1−White leads; or 2−White/1−Red Lead.

TD1

TD2