Installation & operation – MK Diamond Baldor Motor User Manual

Page 11

Installation & Operation 2-1

MN428

Section 2

Installation & Operation

Overview

Installation should conform to the National Electrical Code as well as local codes and practices. When other

devices are coupled to the motor shaft, be sure to install protective devices to prevent future accidents.

Some protective devices include, coupling, belt guard, chain guard, shaft covers etc. These protect against

accidental contact with moving parts. Machinery that is accessible to personnel should provide further

protection in the form of guard rails, screening, warning signs etc.

Location

It is important that motors be installed in locations that are compatible with motor enclosure and ambient

conditions. Improper selection of the motor enclosure and ambient conditions can lead to reduced operating

life of the motor.

Proper ventilation for the motor must be provided. Obstructed airflow can lead to reduction of motor life.

1.

Open Drip−Proof/WPI motors are intended for use indoors where atmosphere is relatively clean, dry, well

ventilated and non−corrosive.

2.

Totally Enclosed and WPII motors may be installed where dirt, moisture or dust are present and in

outdoor locations.

Severe Duty, IEEE 841 and Washdown Duty enclosed motors are designed for installations with high corrosion

or excessive moisture conditions. These motors should not be placed into an environment where there is the

presence of flammable or combustible vapors, dust or any combustible material, unless specifically designed

for this type of service. IEEE841 motors are suitable for application in Class I Division 2 and Class I Zone 2

areas on sine wave power in accordance with the applicable codes and standards.

Hazardous Locations are those where there is a risk of ignition or explosion due to the presence of

combustible gases, vapors, dust, fibers, or flyings. Facilities requiring special equipment for hazardous

locations are typically classified in accordance with local requirements. In the US market, guidance is provided

by the National Electric Code.

EMC Compliance Statement for European Union

The motors described in this instruction manual are designed to comply 2004/108/EC . These motors are

commercial in design and not intended for residential use.

Mounting Location

The motor should be installed in a location compatible with the motor enclosure and specific ambient. To allow

adequate air flow, the following clearances must be maintained between the motor and any obstruction:

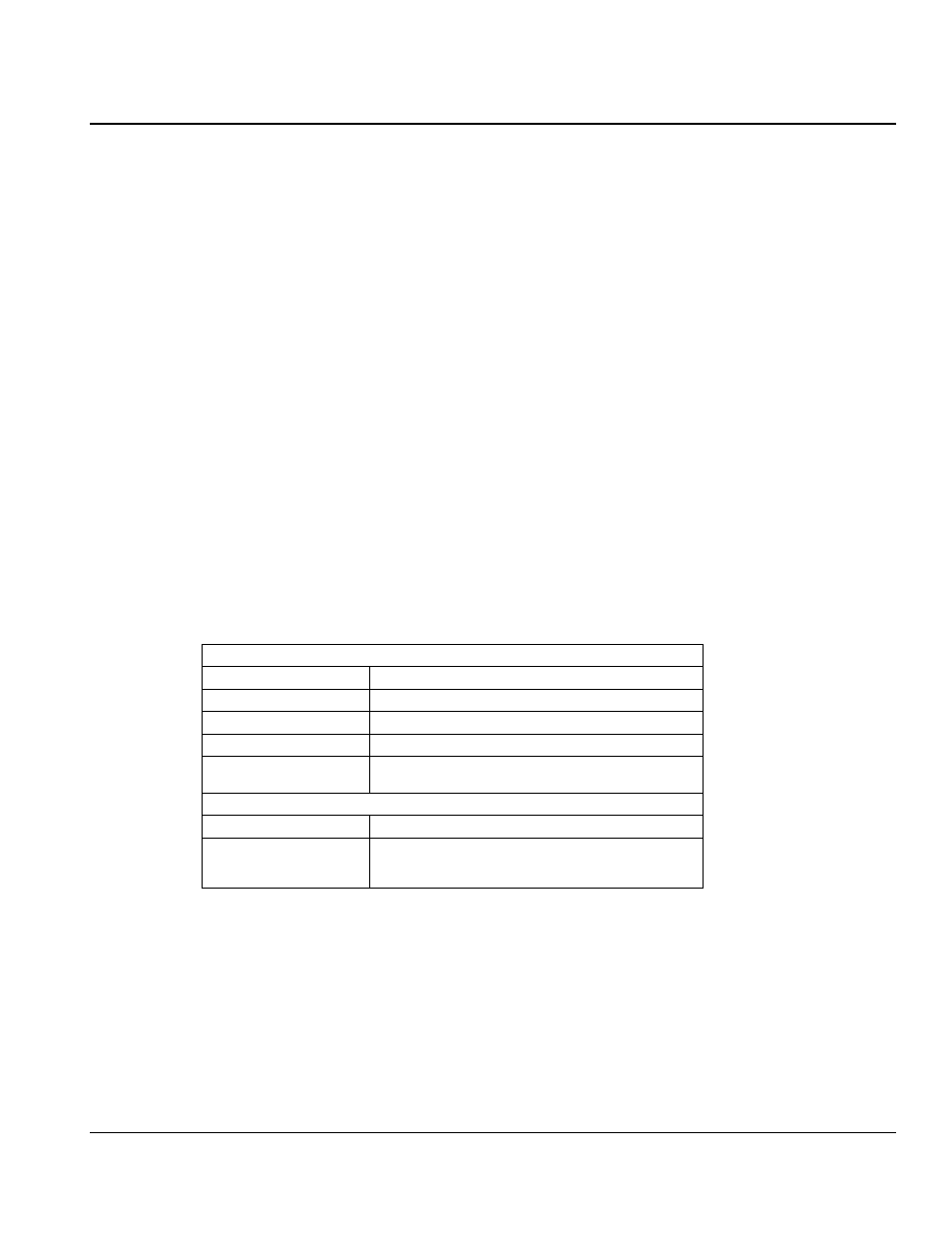

Table 2-1 Enclosure Clearance

TEFC / TENV ( IC0141 ) Enclosures

Fan Cover Air Intake

180 − 210T Frame 1” ( 25mm)

Fan Cover Air Intake

250 − 449T Frame 4” (100mm)

IEC 112 − 132 1” ( 25mm)

IEC 160 − 280 4” (100mm)

Exhaust

Envelope equal to the P Dimension on the motor

dimension sheet

OPEN/Protected Enclosures

Bracket Intake

Same as TEFC

Frame Exhaust

Exhaust out the sides envelope

A minimum of the P dimension plus 2” (50mm)

Exhaust out the end same as intake.

The motor must be securely installed to a rigid foundation or mounting surface to minimize vibration and

maintain alignment between the motor and shaft load. Failure to provide a proper mounting surface may cause

vibration, misalignment and bearing damage.

Foundation caps and sole plates are designed to act as spacers for the equipment they support. If these

devices are used, be sure that they are evenly supported by the foundation or mounting surface.

When installation is complete and accurate alignment of the motor and load is accomplished, the base should

be grouted to the foundation to maintain this alignment.

The standard motor base is designed for horizontal or vertical mounting. Adjustable or sliding rails are

designed for horizontal mounting only. Consult your Baldor distributor or authorized Baldor Service Center for

further information.